Durable PVC Coated Wire for Sale - High Quality & Protection

Ago . 13, 2025 05:00

Understanding the Market Dynamics of PVC Coated Wire

The global market for pvc coated wire for sale is experiencing robust growth, primarily propelled by escalating demand in construction, agriculture, and security fencing sectors. This expansion is further bolstered by its superior protective qualities and extended service life, making it a preferred choice over conventional wire materials. Recent market analyses project a significant compound annual growth rate (CAGR) for PVC coated wire, indicating its increasing adoption in both developed and emerging economies. The rising emphasis on durable, low-maintenance infrastructure and perimeter security solutions consistently fuels this demand. Procurement specialists and project managers recognize the inherent value proposition of PVC coated wire, which offers an optimal balance of performance, longevity, and aesthetic versatility across diverse applications.

Technological advancements continue to enhance the properties of pvc coated wire, introducing variations with improved UV resistance, flame retardancy, and specialized color options. This adaptability allows it to meet stringent industry standards and aesthetic requirements. For instance, the demand for pvc coated galvanized wire is particularly strong in environments prone to corrosion, such as coastal regions or industrial zones. Furthermore, the push for sustainable building materials and practices, coupled with a focus on reducing replacement cycles, positions pvc coated wire for sale as an environmentally conscious and economically viable investment. Understanding these macro trends is vital for stakeholders looking to leverage the full potential of this versatile material in their upcoming projects.

The Engineering Behind PVC Coated Wire: A Detailed Process Overview

The manufacturing of PVC coated wire is a precise, multi-stage process designed to impart exceptional protective and aesthetic qualities to a steel core. It begins with high-quality low-carbon steel wire, chosen for its ductility and inherent strength. The wire first undergoes drawing, a process that reduces its diameter and enhances its tensile strength to meet specific gauge requirements. Following this, an annealing process is typically performed, which involves heating the wire to a precise temperature and then slowly cooling it. This heat treatment softens the wire, making it more pliable and easier to handle during subsequent coating stages, while still retaining its structural integrity for applications requiring resilience.

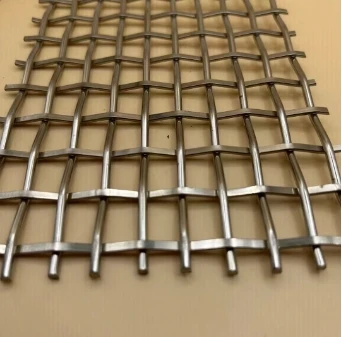

For superior corrosion resistance, the annealed wire is then hot-dip galvanized. This critical step involves immersing the wire in a bath of molten zinc, forming a metallurgically bonded, uniform zinc coating that acts as a primary sacrificial barrier against rust and corrosion. The thickness of this zinc layer is meticulously controlled to meet standards such as ASTM A641. After galvanization, the wire is meticulously cleaned to ensure optimal adhesion of the PVC. The PVC coating itself is applied through an extrusion process, where the galvanized wire passes through a die and is uniformly enveloped by molten Polyvinyl Chloride compound. Precise temperature regulation and extrusion speed are paramount to ensure consistent coating thickness and a smooth finish, free from imperfections. This results in products like pvc coated galvanized steel wire, renowned for its dual-layer protection. Rigorous quality control, adhering to ISO 9001 standards, is maintained throughout, ensuring each batch of pvc coated wire for sale meets stringent performance criteria for its intended use in industries such as petrochemical, metallurgy, and water treatment where resistance to harsh elements is vital.

Key Technical Parameters and Performance Specifications

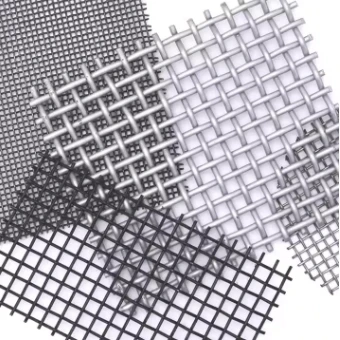

The technical efficacy of pvc coated wire is defined by a series of critical parameters that dictate its suitability for diverse applications. These specifications typically include the core wire diameter (often expressed in BWG – Birmingham Wire Gauge), the uniform thickness of the PVC coating, and the resultant overall wire diameter. For instance, a common configuration for fencing applications might involve a 2.5mm (12 BWG) galvanized core wire with a 1.0mm PVC coating, leading to an overall diameter of 4.5mm. This precise layering contributes significantly to the wire's durability and protective capabilities. The tensile strength of the underlying steel wire is also a key parameter, typically ranging from 350 to 550 N/mm², providing the necessary structural integrity for various load-bearing and tension applications.

Beyond dimensional attributes, the performance of pvc coated gi wire is evaluated based on its resistance to environmental stressors. This includes its tolerance to a wide temperature range, typically from -30°C to +70°C, its UV stability to prevent degradation from sunlight, and its resistance to abrasion, chemicals, and general weathering. A high-quality PVC coating extends the wire's operational lifespan by decades, drastically reducing maintenance and replacement costs. The table below presents typical product specifications for various gauges of pvc coated wire for sale, highlighting the versatility and robustness of this material. These figures are instrumental for engineers and purchasers in selecting the precise product variant that aligns with their project's technical and budgetary requirements.

| Core Wire Diameter (mm) | BWG Gauge | PVC Coating Thickness (mm) | Overall Diameter (mm) | Tensile Strength (N/mm²) | Typical Lifespan (Years) |

|---|---|---|---|---|---|

| 0.9 | 20 | 0.5 - 0.7 | 1.9 - 2.3 | 350-550 | 15-25 |

| 1.6 | 16 | 0.8 - 1.0 | 3.2 - 3.6 | 350-550 | 20-30 |

| 2.5 | 12 | 1.0 - 1.2 | 4.5 - 4.9 | 350-550 | 25-30+ |

| 4.0 | 8 | 1.0 - 1.5 | 6.0 - 7.0 | 350-550 | 25-30+ |

Unmatched Advantages: Why PVC Coated Wire Excels

The core strength of PVC coated wire lies in its unparalleled resistance to environmental degradation. The robust PVC layer forms an impenetrable barrier, shielding the underlying steel from corrosive agents such as moisture, road salts, agricultural chemicals, and industrial pollutants. This significantly extends the wire's operational lifespan, often enabling it to last two to three times longer than bare galvanized wire in challenging conditions. The long-term durability provided by the PVC coating directly translates into substantial cost savings by reducing the frequency of replacement and associated labor and material expenses. This characteristic is particularly beneficial in aggressive environments, ensuring structural integrity and safety for prolonged periods.

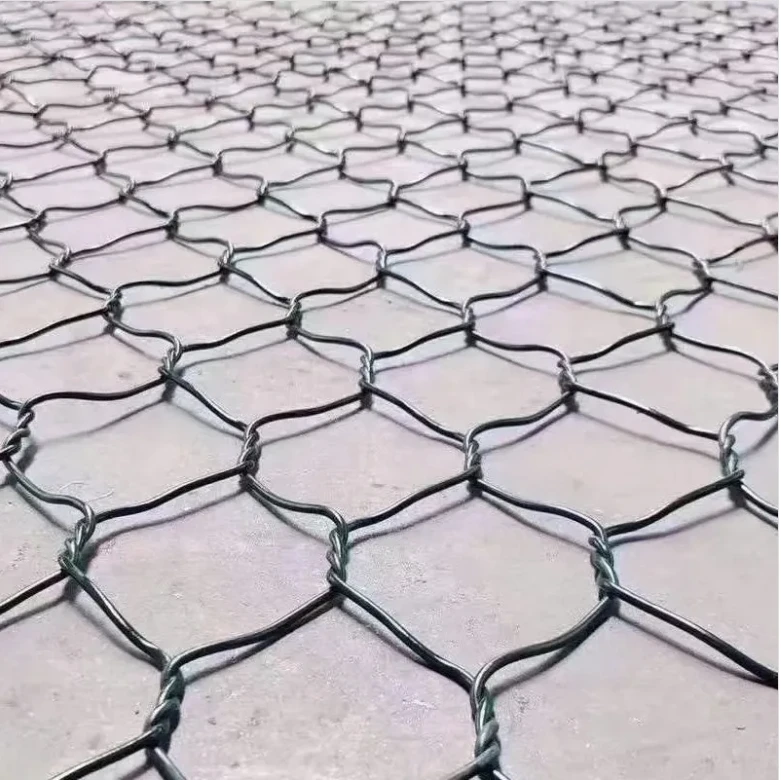

Beyond its exceptional corrosion protection, pvc coated gi wire offers several other distinct advantages. Its smooth, resilient surface exhibits excellent abrasion resistance, which is crucial in applications involving friction or movement. The PVC material also provides effective electrical insulation, enhancing safety in certain setups. Furthermore, the low-maintenance nature of PVC coated wire means it requires minimal upkeep after installation, contributing to reduced operational costs. Aesthetically, pvc coated wire for sale is available in a broad spectrum of colors, allowing it to seamlessly blend into various landscapes or serve specific demarcation purposes, as seen with popular options like black pvc chain wire used extensively in security fencing. This combination of protective, functional, and visual attributes makes it an ideal choice for durable and adaptable wire solutions.

Diverse Application Scenarios Across Industries

The inherent versatility and robust characteristics of PVC coated wire make it an indispensable material across a wide array of industrial and commercial applications. In the agricultural sector, it is extensively used for vineyard trellising, orchard support systems, and protective enclosures for livestock and crops, where its resistance to weather and chemicals ensures long-term reliability. For residential, commercial, and industrial security, products like black pvc chain wire are the standard for chain link fencing, providing both formidable security and an appealing visual finish that integrates well with architectural and natural surroundings. Its resilience against environmental factors ensures minimal degradation over time, even in exposed conditions.

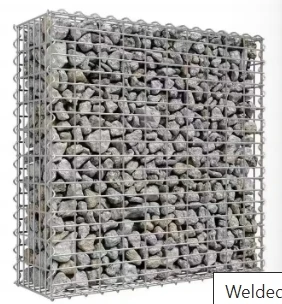

Beyond fencing, pvc coated wire for sale plays a crucial role in construction as tying wire for rebar, and in gabion baskets for erosion control, riverbank stabilization, and architectural features. Its anti-corrosive properties are highly valued in marine and aquatic environments, making it ideal for aquaculture cages, oyster cultivation systems, and shoreline protection barriers where constant exposure to saltwater demands exceptional material resilience. Moreover, its electrical insulation properties make it suitable for certain cable management applications and low-voltage wiring. The ability to tailor the wire's gauge, coating thickness, and color allows for highly specialized applications, from supporting delicate plants in nurseries to securing heavy industrial components in corrosive petrochemical or mining environments, demonstrating its adaptability across a spectrum of demanding uses.

Choosing Your Supplier: Manufacturer Comparison and Custom Solutions

When sourcing pvc coated wire, the selection of a reputable manufacturer is paramount to ensure consistent quality, timely delivery, and competitive pricing. Key evaluation criteria should include the manufacturer's adherence to international quality standards such as ISO 9001, their specific material certifications (e.g., ASTM standards for wire and coating), and their in-house quality assurance protocols. A transparent supplier will readily provide material test reports and certification documentation, offering verifiable proof of product integrity. Beyond standard product lines, the capacity for custom manufacturing solutions is a significant advantage. This allows for precise tailoring of wire gauges, PVC coating thicknesses, specific color matching, and the integration of specialized additives for enhanced properties like increased UV stability or fire resistance to meet unique project specifications.

A thorough comparison of manufacturers for pvc coated wire for sale should also consider their production capacity, lead times for both standard and custom orders, and their logistical capabilities for domestic and international shipments. Experienced B2B suppliers, particularly those with a long-standing track record in serving large-scale industrial and infrastructure projects, often possess superior technical expertise and customer support. They can offer valuable insights during the design and planning phases, helping to optimize material selection for specific environmental challenges or performance requirements. Engaging with a manufacturer that offers comprehensive pre-sales consultation and robust post-sales support ensures a streamlined procurement process and minimizes potential project disruptions, securing the long-term success of your investment.

Proven Success: Real-World Application Cases

The reliability and performance of PVC coated wire are consistently validated through its successful deployment in diverse and demanding applications worldwide. One compelling example is a large-scale solar farm project located in a desert environment, where extreme temperatures and abrasive sand necessitate highly durable materials. Conventional galvanized wires previously used for perimeter fencing showed rapid degradation. By switching to high-quality pvc coated galvanized steel wire, the project owners observed a dramatic increase in fence lifespan, projecting over 25 years of service with minimal maintenance, leading to substantial long-term cost efficiencies and enhanced site security. This case demonstrates the material's resilience under harsh climatic conditions.

Another notable success story involves a major chemical processing plant that required robust and corrosion-resistant wire for structural mesh and containment applications. The acidic and alkaline atmospheres within the plant rapidly corroded untreated metals. The implementation of specialized pvc coated gi wire, engineered with enhanced chemical resistance, proved to be an ideal solution, preventing material degradation and ensuring operational safety and continuity. Customer testimonials frequently highlight the ease of installation and the consistent, high-performance characteristics of our pvc coated wire for sale, even in the most challenging industrial settings. These practical applications underscore the tangible benefits and superior return on investment delivered by selecting premium PVC coated wire solutions for critical infrastructure and industrial requirements.

Frequently Asked Questions (FAQ) about PVC Coated Wire

-

Q: How does the PVC coating extend the lifespan of the wire?

A: The PVC coating acts as a robust, impermeable barrier that protects the underlying steel (and galvanized layer, if present) from moisture, oxygen, chemicals, and UV radiation, which are primary causes of corrosion and degradation. This significantly slows down the aging process of the metal core, extending the overall service life of pvc coated wire to 20-30 years in many environments.

-

Q: Is pvc coated wire for sale suitable for harsh industrial chemical environments?

A: Yes, PVC is inherently resistant to a wide range of acids, alkalis, and salts, making it highly suitable for many industrial chemical environments. For extreme conditions, specialized PVC compounds with enhanced chemical resistance can be formulated. It's crucial to specify the exact chemical exposure to your supplier for optimal material selection.

-

Q: Can the color of black pvc chain wire be customized?

A: Absolutely. While black is a common choice for its aesthetic appeal and UV stability, PVC coatings can be produced in virtually any RAL color to match specific project designs, corporate branding, or environmental blending requirements. Custom colors are often available for minimum order quantities, providing significant flexibility for bespoke applications.

Seamless Procurement: Delivery, Warranty, and Expert Support

Ensuring a smooth and reliable procurement process for industrial materials like pvc coated wire is crucial for project continuity. We are committed to transparent and efficient logistics, providing clear delivery schedules tailored to meet diverse project timelines, whether for domestic distribution or complex international shipments. Our standard lead times for typical product orders range from 10-20 business days, with established protocols for accommodating expedited requests or large-volume contracts requiring specialized handling. Each outgoing shipment undergoes a rigorous final quality assurance check, guaranteeing that the delivered product strictly adheres to agreed-upon specifications and quality benchmarks, affirming its readiness for immediate deployment.

To underscore our unwavering confidence in product quality and our dedication to client satisfaction, all our pvc coated galvanized wire solutions are backed by a comprehensive warranty. This warranty, typically ranging from 5 to 10 years depending on the product grade and specific application, covers manufacturing defects and ensures long-term performance under normal operating conditions. Our commitment extends beyond the point of sale; a team of highly experienced technical support specialists is readily available to provide expert guidance on product selection, offer installation best practices, and address any post-purchase inquiries. With over 25 years of specialized experience in the industry, we pride ourselves on delivering not just a product, but a complete, reliable solution supported by unparalleled technical expertise and customer service, making us a trusted partner for your `pvc coated wire for sale` needs.

References and Further Reading

- ASTM International. (2023). "Standard Specification for Zinc-Coated (Galvanized) Steel Barbed Wire". ASTM A121/A121M.

- ISO. (2022). "Quality management systems — Requirements". ISO 9001.

- Polyvinyl Chloride (PVC) Global Market Research Report, MarketsandMarkets. (Latest Edition).

- "The Role of Polymer Coatings in Corrosion Protection of Metals," Corrosion Science Journal. (Recent relevant issue, e.g., Vol. 185, 2021).

Related Products

Related News