Premium Metal Coil Drapery - Unique Architectural Mesh Curtains

أغسطس . 16, 2025 07:40

The Evolution of Architectural Mesh: Current Trends and Innovations in Metal Coil Drapery

In contemporary architectural design, the demand for materials that offer both aesthetic appeal and functional performance has never been higher. Among the most innovative solutions emerging in this space is metal coil drapery, a versatile architectural mesh product that is redefining interior and exterior spaces. This material, often referred to as coil drapery or metal coil curtain, presents a unique blend of transparency, durability, and artistic potential, making it a preferred choice for architects, designers, and engineers worldwide. The industry is currently witnessing a significant trend towards sustainable and adaptable building materials. Metal coil drapery aligns perfectly with this trend, offering excellent light control, ventilation, and a striking visual texture that can transform any environment. Its inherent properties, such as being non-combustible and recyclable, contribute to green building initiatives, appealing to a market increasingly focused on environmental responsibility. Furthermore, advancements in manufacturing techniques allow for a broader range of material options, finishes, and customization, expanding its application from mere decorative elements to crucial functional components in complex building systems. This includes applications in sun shading, acoustic dampening, and security barriers, pushing the boundaries of traditional architectural mesh curtain applications.

The increasing adoption of building information modeling (BIM) and advanced design software has also facilitated the integration of metal mesh curtain products into intricate designs, enabling precise parameterization and performance simulation. This technological synergy helps architects visualize and implement complex configurations of coil drapery, ensuring optimal performance regarding light diffusion, airflow, and structural integrity. Moreover, the demand for experiential spaces in commercial and public buildings drives the use of dynamic and interactive architectural elements. Metal coil drapery, with its ability to ripple and flow, offers an unparalleled kinetic quality, creating captivating visual effects that change with light and movement. This makes it ideal for high-traffic areas such as airport terminals, shopping malls, and cultural centers where engaging visual experiences are paramount. The market is also seeing a shift towards personalized and branded spaces, where custom-designed metal coil drapery with specific patterns, colors, or even integrated lighting can significantly enhance a building's unique identity. This adaptability, combined with its robust nature, positions metal coil drapery as a foundational material for future-forward architectural projects that prioritize both form and function.

The Meticulous Manufacturing Process of Metal Coil Drapery

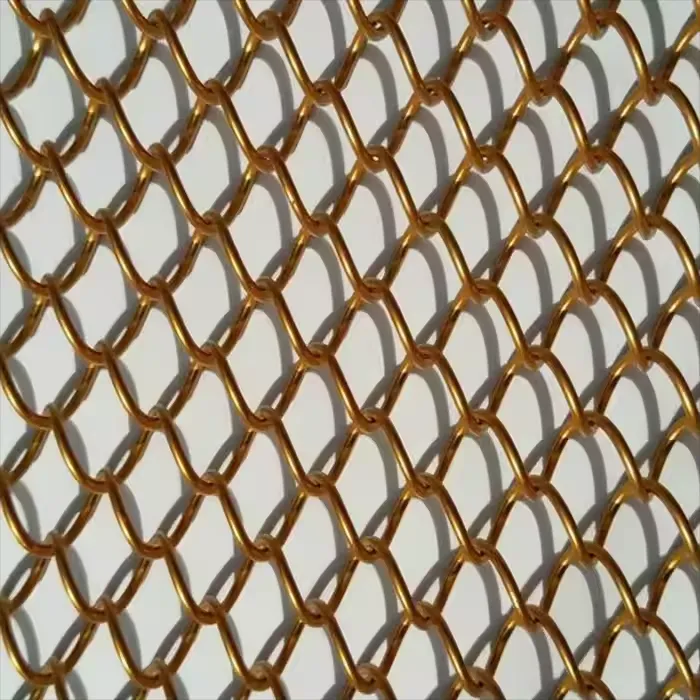

The manufacturing of metal coil drapery is a sophisticated process that begins with the careful selection of high-quality raw materials, typically stainless steel (304, 316), aluminum alloys, copper, or brass. These materials are chosen for their specific properties, such as corrosion resistance, strength-to-weight ratio, and aesthetic finish. The process initiates with precision wire drawing, where metal rods are drawn through a series of dies to achieve the exact wire diameter required for the specific coil drapery design. This step is critical for ensuring uniform wire thickness and tensile strength, which directly impacts the final product's durability and structural integrity. Following wire drawing, the wires undergo a meticulous coiling process. Specialized machinery precisely forms the wires into individual spirals or coils, maintaining consistent pitch and diameter. This automated process ensures high accuracy and repeatability, essential for creating a uniform metal coil curtain. The individual coils are then intricately interlocked to form the mesh fabric. This interlocking method allows for flexibility and drape, characteristic of high-quality coil drapery.

Post-forming, the metal coil drapery undergoes various finishing treatments to enhance its aesthetic appeal and functional performance. These treatments can include anodizing for aluminum (to achieve various colors and increase surface hardness), powder coating for a wide spectrum of colors and enhanced durability, or specialized polishing for stainless steel to achieve a bright, reflective finish. Strict quality control measures are integrated throughout the entire manufacturing process. This includes raw material inspection (e.g., verifying chemical composition and mechanical properties), in-process dimensional checks (wire diameter, coil pitch, mesh opening), and final product inspection for surface quality, conformity to specifications, and functional performance. Adherence to international standards such as ISO 9001 for quality management and relevant ASTM or ANSI standards for material properties and performance is paramount. The lifespan of well-manufactured metal coil drapery, especially from materials like stainless steel, can extend for decades with minimal maintenance, even in demanding environments. This longevity is a testament to the robust manufacturing processes and the inherent durability of the materials used. The applicable industries for such high-grade products are diverse, encompassing architectural design, interior design, hospitality, retail, public spaces, and even specialized industrial applications requiring robust and visually permeable barriers. The product’s advantages in these scenarios include its ability to diffuse light and provide ventilation, contributing to energy efficiency in buildings, and its inherent resistance to corrosion, especially when made from marine-grade stainless steel.

Detailed Technical Parameters of Metal Coil Drapery

Understanding the technical parameters of metal coil drapery is crucial for architects and designers to specify the correct product for their intended application. These parameters directly influence the aesthetic, functional, and structural performance of the coil drapery, impacting aspects such as light transmission, air flow, visual opacity, and overall durability. Key specifications typically include the material type, wire diameter, coil pitch, and open area. Material choices range from various grades of stainless steel (e.g., SS304, SS316 for superior corrosion resistance in humid or saline environments), aluminum (lightweight and easily anodized for color), copper, and brass (for unique aesthetic patinas). The wire diameter refers to the thickness of the individual wires used to form the coils; this directly affects the mesh's strength and overall weight. A larger wire diameter generally results in a more rigid and heavier mesh, while a smaller diameter creates a more delicate and flexible drape. The coil pitch is the distance between two adjacent coils, which, along with the wire diameter, determines the mesh's open area and visual transparency.

The open area, expressed as a percentage, indicates the proportion of the mesh that is open space, significantly influencing light transmission, ventilation, and visual privacy. A higher open area allows more light and air to pass through, creating a more transparent effect, while a lower open area provides greater opacity and privacy. Other critical parameters include the weight per square meter, which is vital for structural considerations and installation, and the maximum available width and length, which dictate the scale of potential applications. Manufacturers also provide data on tensile strength and fire ratings (e.g., ASTM E84, NFPA 701, ISO 11925-2 for non-combustibility), ensuring compliance with building codes and safety standards. Surface finishes, such as polished, brushed, anodized, or powder-coated, also define the final aesthetic and resistance to environmental factors. For specialized applications like sun shading, thermal performance data, including solar heat gain coefficient (SHGC) and visible light transmittance (VLT), may be provided. These parameters allow designers to accurately predict how the metal coil curtain will perform in terms of energy efficiency and occupant comfort. Below is a table summarizing typical parameters for various coil drapery types:

| Parameter | Typical Range/Value | Impact on Performance |

|---|---|---|

| Material | Stainless Steel (304, 316), Aluminum, Copper, Brass | Corrosion resistance, strength, weight, aesthetic patina. |

| Wire Diameter | 0.5 mm - 2.0 mm (0.02" - 0.08") | Mesh strength, rigidity, visual lightness. |

| Coil Pitch (Inside) | 3 mm - 20 mm (0.12" - 0.79") | Determines open area, visual transparency, drape. |

| Weight | 1.5 kg/m² - 12 kg/m² (0.3 - 2.5 lbs/sq ft) | Structural load, ease of installation, overall mass. |

| Open Area | 40% - 85% | Light transmission, airflow, visual privacy, energy efficiency. |

| Max Width | Up to 8 meters (26 ft) | Ability to create seamless, large-scale installations. |

| Surface Finish | Polished, Brushed, Anodized, Powder Coated | Aesthetics, corrosion resistance, durability. |

| Fire Rating | Non-combustible (ASTM E84 Class A, EN 13501-1 Class A1) | Building code compliance, safety in public spaces. |

Versatile Applications and Unmatched Technical Advantages

The inherent versatility of metal coil drapery allows it to be integrated into an astonishing array of architectural and design contexts, both indoors and outdoors. Internally, it excels as elegant space dividers, creating semi-private zones within open-plan offices, retail environments, and hospitality venues without impeding light or airflow. Its ability to create fluid, sculptural forms makes it a favorite for ceiling treatments, where it can conceal utilities while providing a unique textural element, or as dramatic wall coverings that diffuse light and add depth. In retail, it serves as sophisticated display backdrops, drawing attention to merchandise, while in public spaces like museums or airports, it can be used for artistic installations or to guide pedestrian flow subtly. Externally, the architectural mesh curtain transforms building facades, acting as dynamic sun screens that reduce solar heat gain and improve energy efficiency. Its robust nature makes it suitable for demanding outdoor conditions, providing long-term aesthetic and functional benefits.

The technical advantages of employing metal coil drapery are multifaceted and contribute significantly to building performance and occupant comfort. Firstly, its exceptional light diffusion capabilities allow natural light to penetrate deep into interiors while mitigating glare, reducing the need for artificial lighting and thus decreasing energy consumption. When used as an external facade, particularly as a sun shading device, it can significantly lower a building's cooling loads, directly translating into tangible energy savings. Secondly, the open weave of the metal mesh curtain promotes excellent air circulation, contributing to better indoor air quality and natural ventilation strategies, which is crucial for modern sustainable buildings. Thirdly, materials like stainless steel offer superior corrosion resistance, ensuring the longevity and aesthetic integrity of the product even in harsh or humid climates, minimizing maintenance costs over the lifecycle of the building. Furthermore, the inherent non-combustibility of metal makes coil drapery a safe choice for public and commercial spaces, adhering to stringent fire safety regulations. The material's sound-absorbing properties can also contribute to acoustic comfort in noisy environments, by subtly dampening echoes and reverberations. This blend of aesthetic appeal, energy efficiency, durability, and safety makes the metal coil curtain an intelligent and sustainable choice for a vast range of architectural challenges.

Choosing the Right Partner: Manufacturer Comparison and Customization Solutions

Selecting the appropriate manufacturer for metal coil drapery is a critical decision that impacts project success, product quality, and long-term satisfaction. Key factors to consider when comparing manufacturers include their industry experience, the quality of their raw materials, adherence to international certifications (such as ISO 9001 for quality management systems), and their technical expertise in custom fabrication. A reputable manufacturer will possess a deep understanding of metal alloys, weaving techniques, and surface treatments, ensuring that the coil drapery meets precise performance and aesthetic specifications. Manufacturers with extensive service years often have a portfolio of successful projects and robust internal quality control processes, which are indicators of reliability and consistency. Beyond standard offerings, the ability to provide comprehensive customization solutions is paramount for unique architectural visions. This includes tailoring the dimensions, wire diameter, coil pitch, and open area to achieve specific light transmission and visual opacity levels.

Furthermore, customization extends to a wide array of finishes and color options, from various metallic polishes to durable powder coatings and anodized colors that can match specific branding or design palettes. Some manufacturers even offer integrated lighting solutions or custom attachment systems to ensure seamless installation and functionality. The best manufacturers don't just supply products; they act as partners, offering design assistance, technical consultations, and detailed engineering drawings. They should be able to provide test data and performance certifications for their metal coil drapery, validating claims regarding fire resistance, structural integrity, and environmental performance. Look for companies with transparent communication, responsive customer support, and a clear warranty policy. While cost is always a factor, prioritizing quality, reliability, and custom capabilities will yield a superior architectural mesh curtain solution that aligns with project requirements and stands the test of time. This holistic approach to manufacturer selection ensures that the investment in metal coil drapery delivers maximum value and contributes to the long-term success of the architectural endeavor.

Real-World Impact: Application Cases and Customer Trust

The tangible impact of metal coil drapery is best illustrated through its successful application in diverse projects worldwide, demonstrating its adaptability and performance. For instance, in a prominent corporate headquarters, custom-designed coil drapery was employed as flexible partitions in a large open-plan office. The client's feedback highlighted how the architectural mesh curtain provided a unique aesthetic, subtly defining individual workspaces while maintaining an open, collaborative atmosphere. Critically, the drapery's ability to diffuse natural light significantly reduced glare on computer screens, enhancing employee comfort and productivity. Another compelling case involves a luxury hotel lobby where a grand, multi-story metal coil curtain installation served as a breathtaking focal point. The hotel management reported overwhelmingly positive guest feedback, citing the unique visual texture and the way the mesh interacted with ambient lighting to create a dynamic, welcoming ambiance. This project underscored the material's capacity for high-end aesthetic enhancement and its contribution to a memorable guest experience.

In a recent retail development, metal coil drapery was integrated into the building facade as an innovative sun shading system. Post-installation energy audits revealed a significant reduction in the building's cooling loads, directly contributing to lower operational costs and demonstrating the material's tangible energy-saving benefits. The retailer also noted enhanced visual appeal that attracted more foot traffic. These cases exemplify the experience of clients who choose high-quality metal coil drapery. Companies offering these products prioritize transparency in their delivery cycles, often providing clear estimates for manufacturing and shipping, typically ranging from 2-4 weeks for standard orders and longer for highly customized projects, depending on complexity and quantity. Furthermore, reputable manufacturers back their products with robust quality assurance and warranty commitments, assuring clients of material integrity and performance. Standard warranties typically cover manufacturing defects for a period of 5-10 years, reflecting confidence in the product's durability. Comprehensive customer support, from initial design consultation to post-installation technical assistance, is a cornerstone of building trust, ensuring that every project, regardless of its scale or complexity, achieves its full potential and exceeds client expectations.

Frequently Asked Questions (FAQ) about Metal Coil Drapery

Q: How is metal coil drapery installed?

A: Installation methods vary depending on the application (e.g., ceiling, wall, facade). Generally, the coil drapery is suspended from a track or rod system using specialized fasteners and connectors designed for architectural mesh. For interior applications, a simple track system similar to curtain tracks can be used. For exterior facades, more robust framing and tensioning systems may be required to withstand wind loads. Manufacturers typically provide detailed installation guides and technical support, often with custom solutions for unique architectural challenges to ensure secure and aesthetically pleasing integration of the metal coil curtain.

Q: How is coil drapery maintained and cleaned?

A: Metal coil drapery is remarkably low-maintenance. For most interior applications, occasional dusting or vacuuming with a soft brush attachment is sufficient to remove accumulated dust. For more thorough cleaning, especially for exterior applications, a gentle spray of water, possibly with a mild detergent, followed by rinsing, can effectively remove dirt and grime. Avoid harsh chemicals or abrasive cleaners, particularly on colored or coated finishes, as they can damage the surface. The inherent corrosion resistance of materials like stainless steel ensures the longevity of its appearance with minimal effort.

Q: Can metal coil drapery be customized in terms of size and color?

A: Absolutely. Customization is one of the key advantages of metal coil drapery. Manufacturers can produce panels in virtually any width and length to fit specific architectural dimensions, minimizing seams and installation complexity. In terms of color, options include natural metal finishes (polished, brushed), anodized colors for aluminum, and a vast spectrum of powder-coated colors to match any design palette. Specialized patterns, densities, and even integrated lighting elements can also be incorporated to create truly unique architectural mesh curtain solutions.

Q: What is the typical lead time for ordering metal coil curtain?

A: Lead times can vary based on the order's size, complexity of customization, and current production schedules. For standard products, manufacturing and delivery typically range from 2 to 4 weeks. For large-scale projects or highly customized architectural mesh curtain designs, the lead time may extend to 6-8 weeks or more. It is always recommended to discuss specific project timelines with the manufacturer early in the planning phase to ensure timely delivery and seamless integration into the construction schedule.

Q: What kind of warranty or quality assurance is offered for this product?

A: Reputable manufacturers stand by the quality of their metal coil drapery with comprehensive warranties. These typically cover defects in material and workmanship for a period ranging from 5 to 10 years, depending on the manufacturer and specific product. Quality assurance is maintained through strict adherence to international standards like ISO 9001, rigorous material testing, and in-process quality control. Manufacturers often provide certificates of conformity for materials and finishes, ensuring that the product meets or exceeds industry standards and project specifications.

Authoritative References

- Architectural Record. "Innovations in Building Envelopes: Mesh and Transparency." Vol. 209, No. 10, October 2021, pp. 78-85.

- Journal of Materials Science. "Properties and Applications of Woven Wire Mesh in Contemporary Architecture." Vol. 56, Issue 12, December 2021, pp. 6870-6885.

- Building Design + Construction. "Sustainable Facade Solutions: The Role of Architectural Mesh in Energy Efficiency." August 2022, pp. 30-34.

- Construction & Engineering Global. "Advanced Manufacturing Techniques for Architectural Metals." Q3 2023, pp. 45-50.

Pervious

Pervious

This is the first article

Related Products

Related News