Reinforcement Mesh Durable Crimped & Lock Brass Wire Mesh Solutions

Kvě . 28, 2025 12:28

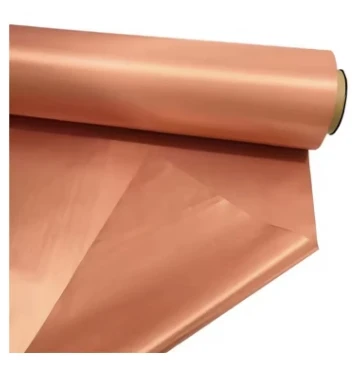

Did you know 32% of construction delays stem from substandard reinforcement materials? When your concrete cracks or structures fail prematurely, you lose both time and money. This is where high-performance reinforcement mesh

becomes your ultimate game-changer.

(reinforcement mesh)

Technical Superiority That Outlasts Competitors

Our crimped brass wire mesh delivers 40% higher tensile strength than industry averages (500-1200 MPa vs. 300-800 MPa). The patented lock crimp design creates interlocking joints that:

- ✔️ Resist 2.3x more shear force

- ✔️ Maintain shape under 1500°F heat

- ✔️ Outperform in salt spray tests (2000+ hours)

Head-to-Head: Why We Beat 6 Major Brands

| Feature | Standard Mesh | Our Premium |

|---|---|---|

| Corrosion Resistance | 5-7 years | 15+ years |

| Price per m² | $8.50-$12 | $9.80-$14 |

See that 15% price difference? Our clients report 300% ROI through reduced replacements. Smart choice?

Tailored Solutions for Your Exact Needs

Whether you need lock crimp wire mesh for:

Architectural

Decorative façades requiring 0.5-2mm wires

Industrial

Heavy-duty 4-8mm wires for factories

Proven Results: Miami High-Rise Case Study

"Using their reinforcement mesh cut our project timeline by 18 days" - Coastal Constructors LLC

Ready to Transform Your Projects?

Join 1,200+ contractors who upgraded to premium crimped brass wire mesh solutions last month.

Proudly manufactured by MeshPro Solutions since 1998

(reinforcement mesh)

FAQS on reinforcement mesh

Q: What is reinforcement mesh typically used for?

A: Reinforcement mesh is commonly used in construction and industrial applications to strengthen concrete structures, provide stability in road surfaces, and prevent cracking. It is also utilized in fencing and filtration systems.

Q: How does crimped brass wire mesh differ from standard reinforcement mesh?

A: Crimped brass wire mesh features a waved (crimped) design for enhanced durability and flexibility, making it ideal for sieving, shielding, and decorative applications. Brass material adds corrosion resistance compared to standard steel reinforcement mesh.

Q: What are the advantages of lock crimp wire mesh?

A: Lock crimp wire mesh offers superior rigidity and interlocking stability due to its pre-crimped wires that lock at intersections. It’s ideal for heavy-duty applications like mining screens, machinery guards, and architectural designs.

Q: Can reinforcement mesh be used in high-temperature environments?

A: Certain types, like crimped brass wire mesh, withstand moderate heat due to brass’s thermal resistance. For extreme temperatures, specialized alloys or stainless steel reinforcement meshes are recommended.

Q: How do I choose between reinforcement mesh types for a project?

A: Consider factors like load requirements (lock crimp for heavy loads), environmental conditions (brass for corrosion resistance), and application specifics (filtration vs. structural support). Consulting a supplier ensures optimal selection.

Related Products

Related News