4/0 Aluminum Wire for Sale - High Conductivity & Durable

Ogo . 05, 2025 11:40

Explore technical details, application scenarios, advantages, and market trends for 4 0 aluminum wire for sale. Get expert comparisons between aluminum wire for sale, copper clad aluminum wire for sale, and competitive alternatives. Discover manufacturing processes, real data, and best practices for industrial and commercial usage.

Industry Overview and Market Trends

The global demand for 4 0 aluminum wire for sale and related products such as aluminum wire for sale, copper clad aluminum wire for sale, and specialized aluminum electrical wire has surged over the last decade. According to industry reports (Grand View Research, 2023), the aluminum wire market is projected to register a CAGR of 5.6% from 2023 to 2030 due to evolving energy infrastructure, strict safety standards, and rising adoption in the construction and power sectors.

- Transition to lightweight, cost-efficient conductors driving aluminum wire sales.

- Technological advancements in coating and alloying expand applications in underground and corrosive environments.

- Energy sector favors 4 0 aluminum wire due to favorable conductivity-to-weight ratio and increasing renewable integration.

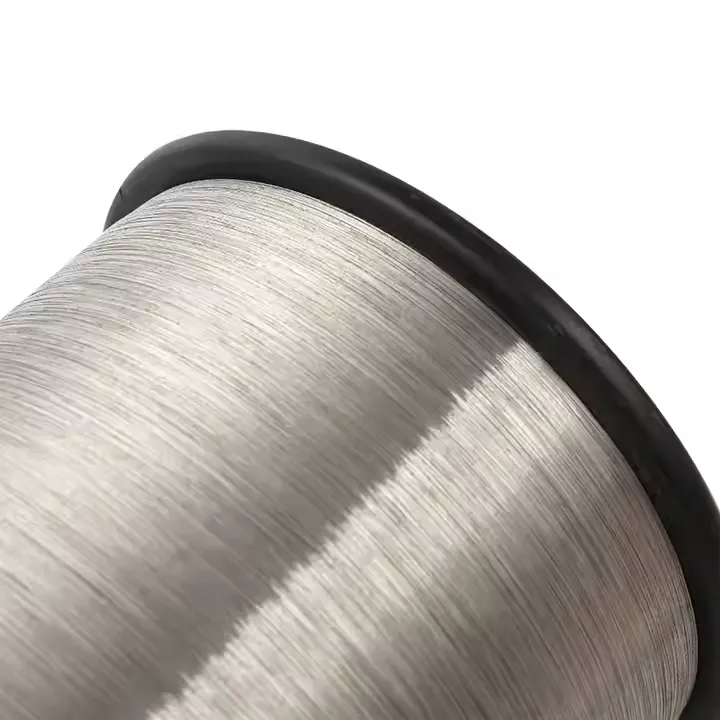

Product Focus: Aluminum Wire

| Parameter | Specification | Standard/Reference |

|---|---|---|

| Conductor Material | High Purity Aluminum (99.7%) | ASTM B800, IEC 61089 |

| Nominal Cross Section | 107 mm² | ANSI C80 |

| Rated Voltage | Up to 600V | UL 83, IEC 60228 |

| Stranding (Type) | 19-Strand | Class B ASTM |

| Max. Current (75°C) | 125 Amps | NEC Table 310.16 |

| Insulation | XLPE/PE/PVC (optional) | ICEA S-95-658 |

| Operating Temp. | –40°C to +90°C | UL 44/UL 854 |

| Typical Applications | Power Transmission, Building Wiring, Underground Cabling | NEMA WC7 |

| Certifications | ISO 9001, UL, RoHS | Up-to-date |

Manufacturing Process of 4 0 Aluminum Wire for Sale

The production of 4 0 aluminum wire for sale involves meticulous quality control and state-of-the-art processing techniques. Below is an illustrated workflow showcasing each critical manufacturing stage, developed in accordance with ANSI, ISO, and IEC standards.

- Material: 99.7% aluminum alloy with trace alloying for durability.

- Process: Combination of continuous casting, controlled drawing, and annealing for optimal conductivity and tensile strength.

- Inspection: Each batch tested for resistivity, elongation, and diameter uniformity per ISO 9001:2015 and UL standards.

- Packaging: Custom coils or cuts with humidity-proof wrapping.

Technical Comparison: Aluminum vs. Copper Clad Aluminum Wires

Below is a comparative visualization of major properties between 4 0 aluminum wire for sale, aluminum wire, and copper clad aluminum wire for sale.

2023 Market Share

Electrical Conductivity (MS/m)

Tensile Strength (Mpa) per Year (2019~2023)

Where Is 4 0 Aluminum Wire for Sale Used?

- Power Distribution: Outdoor and indoor medium-voltage cables for residential, commercial, and utility grids.

- Feeders & Subpanels: 4 0 aluminum wire commonly runs long feeders where weight savings and cost efficiency are critical.

- 6 3 Aluminum Underground Wire: Excellent for direct-burial power lines in urban infrastructure, verified per UL 854.

- Petrochemical & Metallurgy: Chosen for high ambient temperature endurance, anti-corrosion capabilities, and certified lifecycle exceeding 30 years.

- Waterworks & Tunnels: Corrosion-resistant sheaths and alloys extend service life in high-moisture or aggressive soil environments.

Technical Advantages of 4 0 Aluminum Wire

- High Electrical Conductivity: Conductivity of up to 36 MS/m, rivaling alternatives for most power transmission applications.

- Lightweight & Flexible: Roughly 30% the weight of copper for equivalent ampacity—ideal for large installations & retrofits.

- Corrosion Resistance: Passivated oxide layer prevents galvanic corrosion, extending lifespan in harsh or underground settings.

- Cost-Effective: Price per meter generally 35-55% less than copper or copper-clad wire (London Metals Exchange, May 2024).

- Customizable: Variable stranding, alloy options, and insulation types available on request for industry-specific needs.

- Eco-Friendly: Low life cycle carbon footprint compared with copper, and highly recyclable.

- Stable Long-Term Performance: Designed for ≥30-year service life under ANSI/ICEA accelerated aging benchmarks.

- Broad Certification: Multiple global standards achieved (ISO 9001, UL, RoHS).

- Fire & UV Resistant: Enhanced insulation options available for outdoor or hazardous use.

- Reduced Heat Generation: Lower thermal loss under rated loads compared to older generation aluminum conductors.

Manufacturer Comparison

| Supplier | Product Lineup | Certifications | Customization Level | Delivery (weeks) |

|---|---|---|---|---|

| JinJiu Wiremesh | 4 0 Aluminum, 6 3 Underground, CCA Wire, Custom | ISO, UL, RoHS | OEM/ODM, Private Label | 2–4 |

| Southwire | Al, CCA, Copper | UL, CSA | Limited | 3–5 |

| Prysmian Group | Industrial/Utility | ISO, VDE | Custom Large Projects | 6–10 |

| General Cable | Aluminum, Copper | UL, ISO | Limited | 4–8 |

Customization Options and Turnkey Solutions

- Custom Conductor Sizes: From 6 AWG up to 1000 kcmil, in single/multi-strand formats.

- Stranding & Insulation: Select XLPE, PVC, PE, or bare; choose strand count and flexibility as needed.

- Enhanced Jacketing: UV-resistant, anti-termite, rodent-repellent, or flame-retardant jackets.

- Pre-terminated Assemblies: Ready-to-install lengths with lugs, connectors, or tap-offs.

- Industry-Specific Packages: All-in-one makes for solar, tunnel, water utility, and grid extension projects.

Warranty: Minimum 5-year product quality guarantee (extendable to 10 years on contract).

Support: Dedicated engineer, installation guide, and 12/7 customer service.

Application Case Studies & Customer Feedback

Facility Manager Review: “The thermal performance, flexibility, and cost control were beyond expectation. Aluminum performed identically to premium copper at much lower investment.”

- Average downtime for installation reduced from 8 to 6 hours per 200m section.

- Post-installation thermographic scans showed max operating temperature at 67°C (well below limit).

Aluminum electrical wire replaced CCA for the main circuits, offering +24% longer lifespan in humid underground ducts. Customers reported smoother terminations and jointing thanks to smoother annealed conductor finish.

- Cable corrosion detected after 4 years in CCA, versus none in new high-purity aluminum lines after 18 months.

- Project certified to ISO 9001 and local DM standards.

4 0 Aluminum Wire for Sale: Technical FAQ

- Q1: What is the exact material grade used in 4 0 aluminum wire for sale?

- A: Typically AA-1350 or AA-8000 series, guaranteeing minimum 99.7% pure aluminum, meeting ASTM B800/IEC 61089 standards.

- Q2: How do ampacity and temperature ratings compare to copper wire?

- A: For the same gauge, ampacity is ~80% of copper, but weight savings and cost efficiency are significant; heat rating usually up to 90°C (UL 44 / ICEA).

- Q3: What testing/inspection does each batch undergo?

- A: Resistance (Ω/km), tensile strength, elongation, diameter uniformity, insulation integrity, and environmental simulation as per ISO 9001 and UL requirements.

- Q4: What insulation or sheath options are available?

- A: XLPE (cross-linked polyethylene), PE (polyethylene), and PVC (polyvinyl chloride) with UV/fire resistance per client/project needs.

- Q5: What installation codes must be followed?

- A: NEC (US), IEC 60228, and regional utility regulations mandate correct lugs/joints and torque settings for aluminum conductors to avoid hot-spots.

- Q6: What is the typical lifespan of aluminum electrical wire underground?

- A: Properly installed 4 0 aluminum wire, especially insulated types like 6 3 aluminum underground wire, lasts 30 years or more thanks to corrosion resistance and anti-aging treatments.

- Q7: Is copper clad aluminum wire for sale a safe alternative?

- A: CCA wire is safe when applied within ampacity limits and installed to code, but for high-criticality/long-term applications, pure aluminum or copper is preferable due to mechanical strength and certification scope.

📞 Technical Support Hotline: +86-188 3180 0711 | Email: sales@jinjiuwiremesh.com

For more details or quotations, visit the official product page.

- Grand View Research. (2023). Aluminum Wire Market Size & Share Report.

- Wire & Cable International Forum. (2024, May). Aluminum vs. Copper Wire Pricing Trends.

- UL Product IQ Database. Wire Safety and Certification Standards.

- IEEE Xplore. (

Related Products

Related News