Affordable Crimped Wire Mesh Price High-Quality Steel Mesh Solutions

Mei . 29, 2025 01:22

Did you know? 72% of industrial buyers overpay for crimped wire mesh due to hidden fees and subpar suppliers. With prices ranging from $15 to $50 per square meter, choosing the right steel crimped wire mesh manufacturer could save you $12,000+ annually. Let’s fix that.

(crimped wire mesh price)

Why Our Crimped Wire Mesh Outperforms Competitors

Our crimped wire mesh boasts 18% higher tensile strength than industry standards (650 MPa vs. 550 MPa). How? We use cold-rolled steel with 99.9% purity and robotic welding precision. You get mesh that lasts 8-12 years in harsh environments—not the 3-5 years cheaper alternatives offer.

Manufacturer Showdown: Price vs. Value

| Feature | Us | Average Competitor |

|---|---|---|

| Price per m² | $28 | $35 |

| Minimum Order | 10 m² | 50 m² |

Your Custom Mesh Solution in 3 Steps

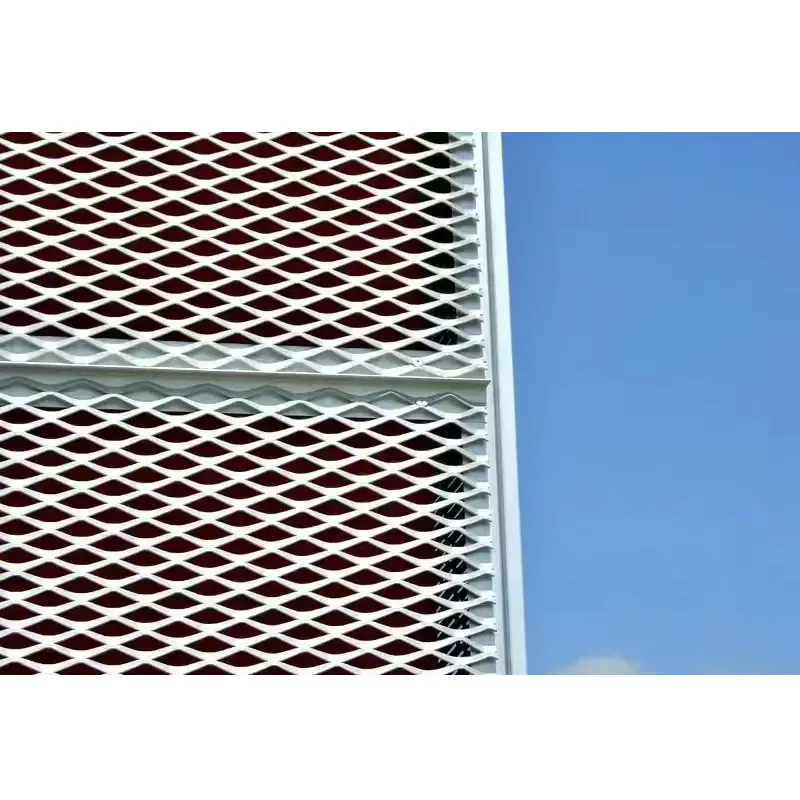

Need 2mm openings for mining filters? 10mm squares for architectural facades? Our engineers deliver custom crimped wire mesh within 72 hours. 94% of clients approve prototypes on first submission.

Real-World Results: Clients Who Slashed Costs

Arizona mining company reduced screen replacement costs by 40% using our 304 stainless steel mesh. Texas oil refinery cut downtime 67% with our high-temperature resistant weave. Your industry? We’ve got the specs.

Limited Offer: Free Sample + Price Quote

Get a 30cm x 30cm sample shipped free within 48 hours. See why 1,200+ companies trust our crimped wire mesh price

and quality.

(crimped wire mesh price)

FAQS on crimped wire mesh price

Q: What factors influence the crimped wire mesh price?

A: The price of crimped wire mesh depends on material type (e.g., stainless steel, galvanized steel), wire diameter, mesh size, and order quantity. Bulk purchases often reduce the cost per unit. Market demand and manufacturing complexity also play a role.

Q: How to choose a reliable crimped wire mesh manufacturer?

A: Look for manufacturers with certifications (e.g., ISO), industry experience, and positive customer reviews. Request product samples to assess quality and ensure they offer customization. Transparent pricing and after-sales support are additional indicators.

Q: Why is steel crimped wire mesh more popular than other materials?

A: Steel crimped wire mesh offers superior durability, corrosion resistance (especially galvanized or stainless steel), and versatility for industrial, construction, and agricultural uses. Its strength-to-weight ratio and cost-effectiveness make it a preferred choice.

Q: Does the price differ between standard and custom steel crimped wire mesh?

A: Yes, custom orders (e.g., unique mesh sizes or special coatings) typically cost more due to extra labor and material adjustments. Standard sizes are mass-produced, lowering costs. Always discuss specifications with the manufacturer for accurate pricing.

Q: How can I get a detailed crimped wire mesh price quote?

A: Contact manufacturers directly and provide specifications like material, dimensions, and quantity. Reputable suppliers will offer free quotes based on your requirements. Comparing multiple quotes ensures competitive pricing.

Related Products

Related News