Welcome to a comprehensive exploration of ring mesh curtain technology, a versatile and aesthetic solution gaining significant traction across diverse industries. At Jinjiu Wire Mesh, we are at the forefront of designing, manufacturing, and exporting high-quality metal ring mesh curtains, offering unparalleled expertise and innovative solutions to our global clientele. This article delves into the intricacies of ring mesh curtain, from its fundamental design and manufacturing processes to its myriad applications and profound technical advantages, ensuring you gain a holistic understanding of this cutting-edge material.

The Evolving Landscape of Architectural and Industrial Mesh Curtains

The demand for intelligent and adaptable material solutions in modern architecture, interior design, and industrial applications continues to surge. Among these, the ring mesh curtain has emerged as a preferred choice, largely due to its unique combination of aesthetic appeal, functional versatility, and robust durability. Unlike traditional solid barriers, metal ring mesh curtain offers dynamic transparency, allowing for controlled light diffusion, ventilation, and visual interaction while providing a distinct architectural texture. Global market analyses indicate a steady growth in the architectural mesh sector, driven by increasing construction activities, a growing preference for sustainable building materials, and the desire for visually striking facades and interior elements. Projections suggest that the market for architectural metal meshes, including ring mesh curtain, will continue its upward trajectory, reaching valuations exceeding several billion dollars in the coming decade, fueled by innovations in material science and design methodologies.

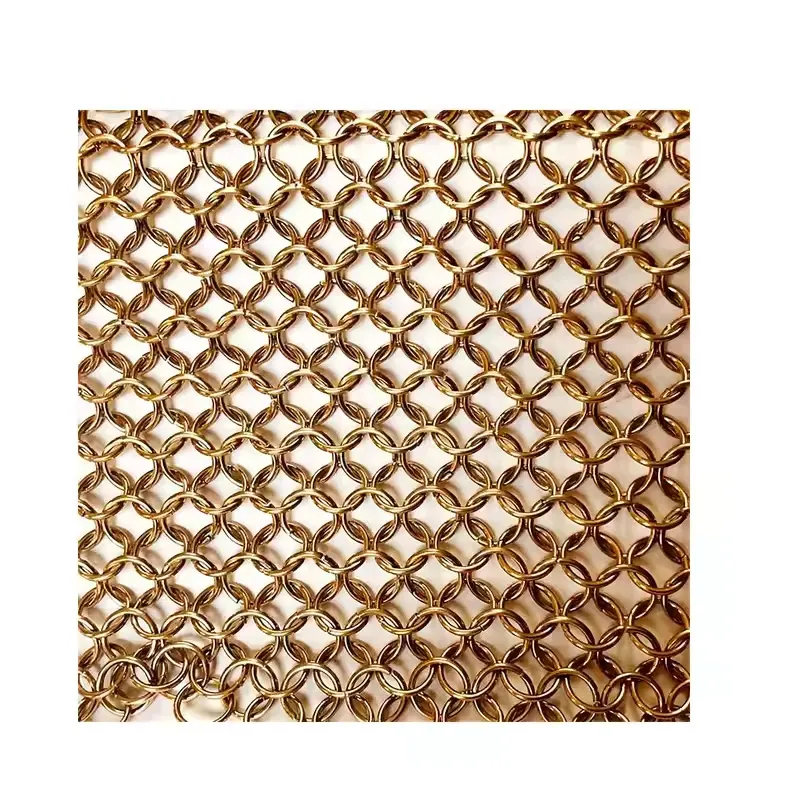

Fig 1: Illustrative application of ring mesh curtain in modern architectural design.

Understanding Ring Mesh Curtain: Technical Specifications and Parameters

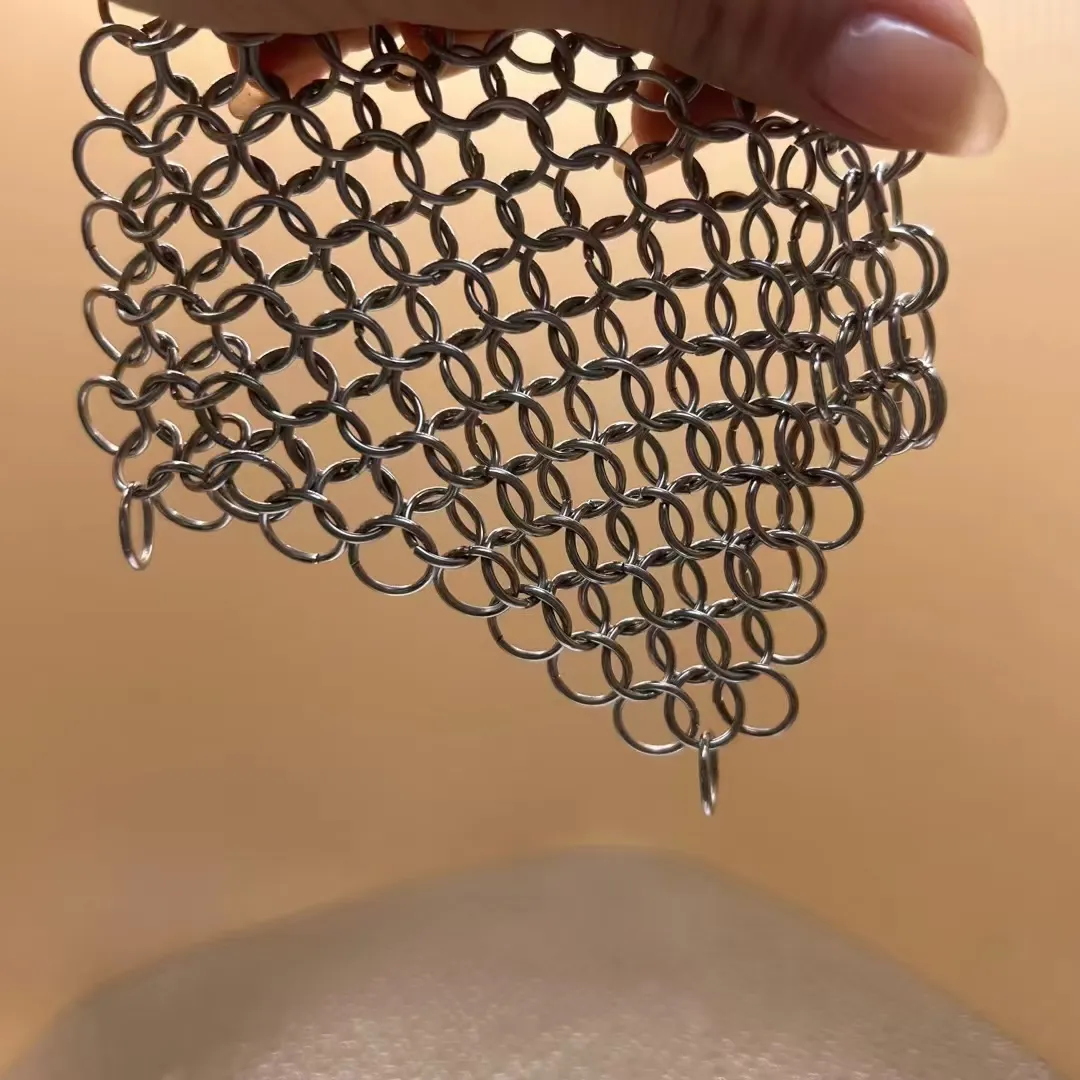

A ring mesh curtain is essentially an assembly of individual metal rings, meticulously linked together to form a flexible, shimmering fabric. The intricate interweaving of these rings creates a material that is both robust and fluid, capable of adapting to various shapes and forms. The fundamental technical parameters define the performance and aesthetic characteristics of the curtain:

- Material Composition: Primarily manufactured from high-grade stainless steel (e.g., SUS 304, 316, 316L for superior corrosion resistance), carbon steel, or aluminum alloys. Specialized coatings or finishes (e.g., anodized aluminum, PVD coatings) can be applied for enhanced durability, color, and specific environmental resistances.

- Ring Diameter: Ranges typically from 8 mm to 20 mm, influencing the visual transparency and structural integrity. Smaller diameters create a denser, more opaque fabric, while larger ones allow for greater light penetration and a more open feel.

- Wire Diameter: The thickness of the wire used to form each ring, typically between 0.8 mm to 2.0 mm. A thicker wire contributes to greater strength and rigidity.

- Weight: Varies significantly based on material, ring diameter, and wire diameter. Stainless steel curtains can range from 4 kg/m² to 10 kg/m², impacting installation requirements and structural considerations.

- Open Area: A critical parameter determining light transmission and ventilation, ranging from 50% to 80% or more, depending on ring configuration.

- Tensile Strength: Measures the material's resistance to breaking under tension, a crucial factor for load-bearing applications, typically exceeding 500 MPa for stainless steel variants.

- Corrosion Resistance: Especially vital for outdoor or high-humidity environments. Stainless steel 316L offers excellent resistance to pitting and crevice corrosion in chloride environments, making it suitable for marine or coastal applications.

Ring Mesh Curtain Typical Specifications Table

| Parameter |

Typical Range |

Remarks |

| Material |

Stainless Steel (304, 316, 316L), Aluminum Alloy, Carbon Steel |

Choice depends on environment and budget. |

| Ring Outer Diameter |

8mm - 20mm |

Smaller for denser look, larger for higher transparency. |

| Wire Diameter |

0.8mm - 2.0mm |

Affects strength and overall weight. |

| Overall Weight |

4 kg/m² - 10 kg/m² (Stainless Steel) |

Crucial for structural load calculations. |

| Open Area |

50% - 80% |

Influences light, ventilation, and visual privacy. |

| Maximum Width |

Up to 10 meters (Customizable) |

Depends on manufacturing capabilities and installation. |

| Maximum Height |

Customizable, virtually unlimited |

Can be joined for larger vertical spans. |

| Surface Finish |

Natural, Polished, Anodized, PVD Coated, Painted |

For aesthetics and additional protection. |

| Fire Rating |

Non-combustible (for metal variants) |

Meets ASTM E84 Class A for flame spread. |

| Sound Absorption |

Moderate (NRC 0.1-0.3, depending on configuration) |

Can help reduce reverberation in large spaces. |

The Meticulous Manufacturing Process of Ring Mesh Curtain

The production of a high-quality ring mesh curtain involves a series of precise and controlled steps, ensuring the integrity, durability, and aesthetic perfection of the final product. As a leading ring mesh curtain factory, Jinjiu Wire Mesh adheres to stringent quality control measures throughout the entire process.

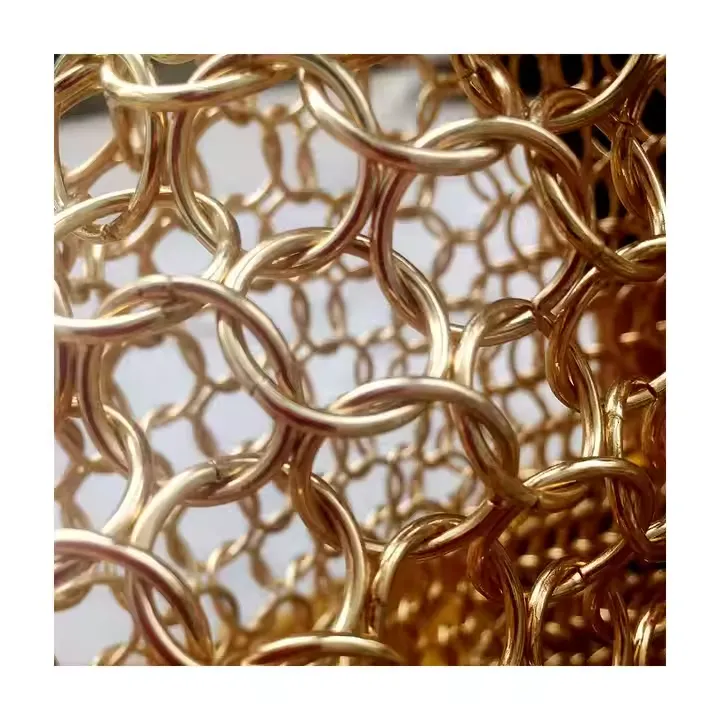

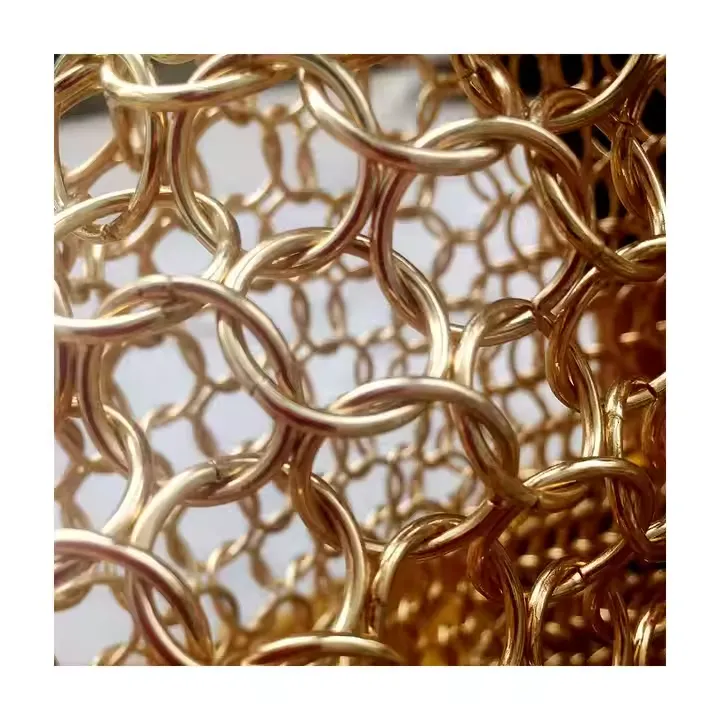

Fig 2: A close-up view of the interlocking rings, showcasing precision in manufacturing.

Detailed Process Flow of Ring Mesh Curtain Production:

⚙️

1. Material Selection & Wire Drawing

The journey begins with the careful selection of raw materials, typically high-grade metal alloys like SUS 304, 316, or specialized aluminum. These materials are chosen based on the desired properties such as corrosion resistance, tensile strength, and aesthetic finish. The raw wire rods are then subjected to a wire drawing process, where they are pulled through a series of progressively smaller dies. This process reduces the wire's diameter to the precise specification (e.g., 0.8mm to 2.0mm), simultaneously enhancing its tensile strength and ensuring uniformity. This step is crucial for achieving the consistent quality required for subsequent forming operations.

➰

2. Ring Forming (Coiling & Cutting)

Once the wire reaches the desired diameter, it is fed into automated ring-forming machines. These machines precisely coil the wire around a mandrel to create individual metal rings of a specific diameter. After coiling, integrated cutting mechanisms accurately sever each ring, ensuring clean edges and uniform size. Advanced CNC (Computer Numerical Control) technology is often employed here to guarantee extreme precision in ring diameter and roundness, minimizing material waste and maximizing consistency. This automation drastically improves production efficiency and product quality.

🔗

3. Ring Linking & Weaving

This is the core assembly stage where the individual rings are meticulously linked together to form the continuous mesh fabric. Rings are interlocked one by one, typically in a four-in-one or six-in-one configuration, where each ring connects with multiple neighboring rings. This linking can be performed manually for intricate patterns or, more commonly for large-scale production, by semi-automated machinery. The critical aspect here is ensuring that each link is secure and consistent, allowing the curtain to drape smoothly and uniformly without weak points. The integrity of these connections is paramount to the curtain's overall strength and longevity.

✨

4. Surface Treatment & Finishing

After the mesh fabric is formed, it undergoes various surface treatments to enhance its aesthetics, durability, and corrosion resistance. Common finishes include:

- Polishing: For a bright, reflective surface.

- Anodizing: For aluminum curtains, providing a durable, corrosion-resistant, and colored finish.

- PVD (Physical Vapor Deposition) Coating: For stainless steel, offering a range of vibrant colors and enhanced scratch resistance.

- Powder Coating/Painting: For custom color requirements, providing an additional layer of protection.

These treatments are vital for the product's performance in challenging environments and for meeting specific architectural design specifications.

🧪

5. Quality Control & Testing

Before shipment, every ring mesh curtain undergoes rigorous quality inspection. This includes:

- Visual Inspection: Checking for defects, inconsistencies in linking, and surface imperfections.

- Dimensional Accuracy: Verifying overall dimensions, ring diameter, and wire diameter against specifications.

- Tensile Strength Testing: Random samples are subjected to load tests to ensure they meet specified tensile strength requirements, adhering to standards like ASTM E8.

- Corrosion Resistance Testing: Salt spray tests (e.g., ASTM B117) are performed on treated samples to evaluate their resistance to corrosive environments.

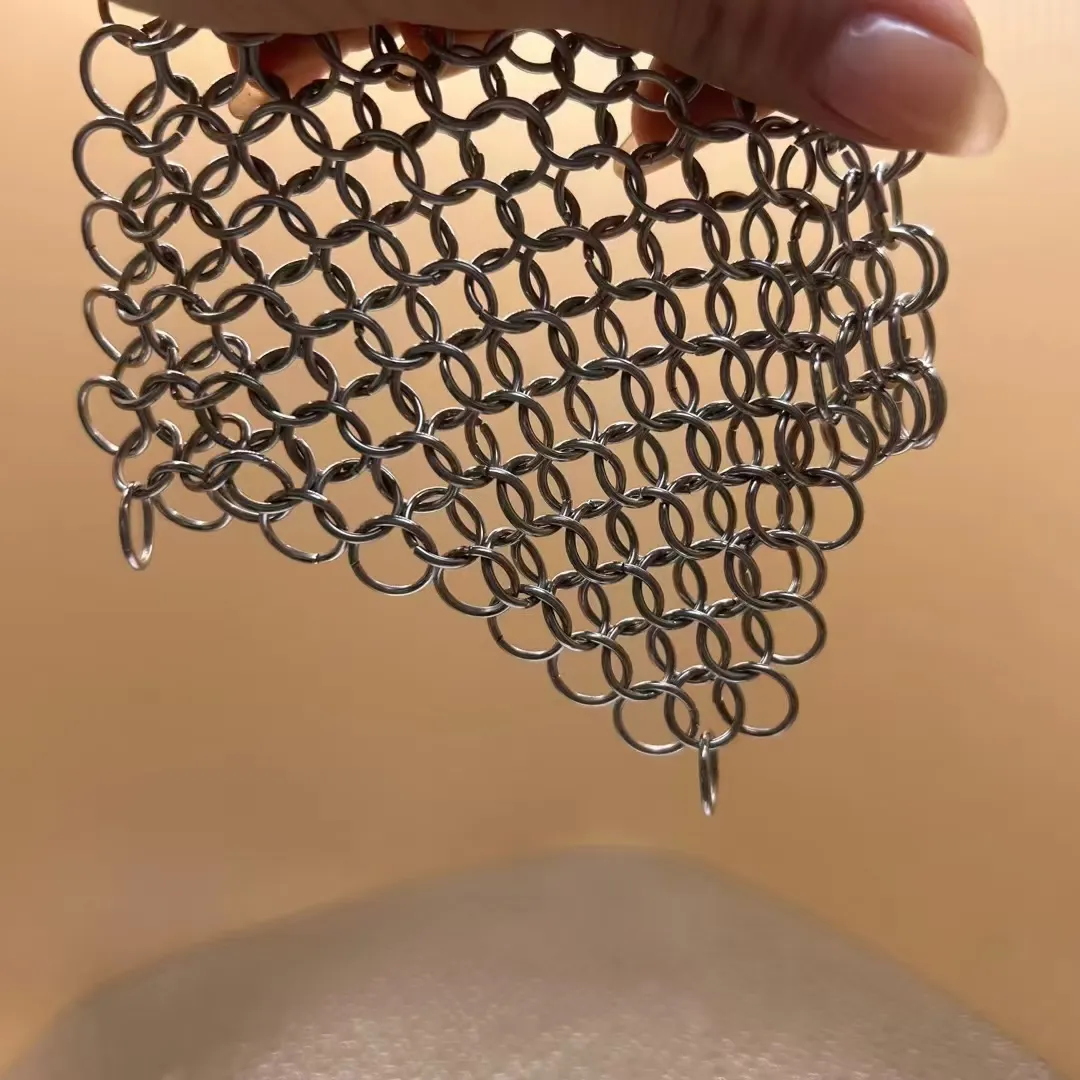

- Drape & Flexibility Test: Ensuring the curtain hangs and folds uniformly, demonstrating its inherent flexibility.

Adherence to international standards such as ISO 9001 (Quality Management) and relevant ASTM/ANSI standards ensures that the product consistently meets or exceeds client expectations. The average service life of a well-maintained stainless steel ring mesh curtain can exceed 20 years, even in challenging outdoor environments, due to these meticulous quality checks and superior material selection.

Applications and Advantages of Ring Mesh Curtain

The versatility of ring mesh curtain allows it to transcend traditional material boundaries, finding innovative applications across a broad spectrum of industries. Its unique properties offer both functional and aesthetic benefits that conventional materials cannot match.

Typical Application Scenarios:

- Architectural Facades & Cladding: For dynamic building envelopes that offer solar shading, wind resistance, and striking visual appeal. It allows light penetration while providing privacy and a unique shimmer.

- Interior Dividers & Space Partitions: Creating elegant, semi-transparent barriers in offices, hotels, shopping malls, and exhibition centers. They define spaces without completely isolating them, promoting airflow and light distribution.

- Ceiling Treatments & Drapery: As decorative elements in large halls, auditoriums, and lobbies, providing a sense of grandeur and acoustic dampening.

- Retail & Exhibition Displays: Backgrounds, signage elements, or unique product display solutions due to their captivating texture and reflectivity.

- Safety Barriers & Guardrails: In industrial settings or public spaces where a flexible, durable, and visually unobtrusive barrier is required for crowd control or light-duty safety.

- Lamp Shades & Lighting Features: Diffusing light to create unique atmospheric effects, particularly in artistic installations.

- Art Installations & Sculptures: Its inherent flexibility and metallic sheen make it a favored material for contemporary art pieces.

Fig 3: Ring mesh curtain elegantly used as an interior space divider in a commercial setting.

Key Technical Advantages:

- Exceptional Aesthetics & Design Flexibility: The shimmering, fluid nature of metal ring mesh curtain provides a captivating visual element. It can be dyed, painted, or finished in various colors, offering immense design freedom. Its ability to conform to various shapes allows for complex, organic forms that are impossible with rigid materials.

- Superior Durability & Longevity: Made from high-grade stainless steel or aluminum, it is inherently resistant to corrosion, rust, and degradation from UV exposure. This makes it ideal for both indoor and outdoor applications, promising a long service life with minimal maintenance.

- Excellent Light & Air Permeability: The open weave allows for controlled transmission of natural light and airflow, reducing the need for artificial lighting and improving ventilation. This translates directly into energy savings and enhanced indoor air quality, contributing to sustainable building practices.

- Fire Resistance: Being composed entirely of metal, ring mesh curtain is non-combustible. It meets stringent fire safety standards (e.g., ASTM E84 Class A), making it a safe choice for public and commercial buildings.

- Acoustic Properties: While not a primary sound-blocking material, the textured surface and open structure of the mesh can help in diffusing sound waves, reducing echo and reverberation in large, open spaces, contributing to better acoustic comfort.

- Easy Installation & Maintenance: The lightweight nature and inherent flexibility simplify installation. Once installed, it requires minimal maintenance, typically just occasional cleaning to remove dust or debris, which can be done with mild detergents and water.

- Environmental Sustainability: Metal ring mesh curtains are often made from recycled content and are fully recyclable at the end of their long lifespan, aligning with green building initiatives and reducing environmental impact.

Choosing Your Ring Mesh Curtain Partner: Manufacturer Comparison and Customization

When investing in ring mesh curtain solutions, selecting the right manufacturer and exporter is paramount to ensuring product quality, performance, and successful project execution. While many suppliers exist, a true ring mesh curtain factory stands out by offering not just a product, but a comprehensive solution backed by expertise, customization capabilities, and unwavering support.

Factors to Consider When Choosing a Ring Mesh Curtain Exporter:

- Experience and Reputation: Look for a company with a proven track record, extensive experience in metal mesh fabrication, and positive client testimonials. Jinjiu Wire Mesh has over two decades of specialized experience in wire mesh products, establishing itself as a reliable ring mesh curtain exporter globally.

- Quality Certifications: Adherence to international quality management systems like ISO 9001 demonstrates a commitment to consistent quality. Product-specific certifications (e.g., material certifications, performance tests) further validate claims.

- Manufacturing Capability: A state-of-the-art ring mesh curtain factory will possess advanced machinery for wire drawing, ring forming, and linking, ensuring precision, efficiency, and scalability for large projects.

- Customization Options: The ability to tailor material, ring size, wire diameter, dimensions, color, and finish to specific project requirements is crucial.

- Technical Support & Engineering: A reputable supplier should offer comprehensive technical assistance, from design consultation and material selection to installation guidance and structural analysis support.

- After-Sales Service & Warranty: Clear warranty policies and responsive customer support are indicators of a trustworthy partner.

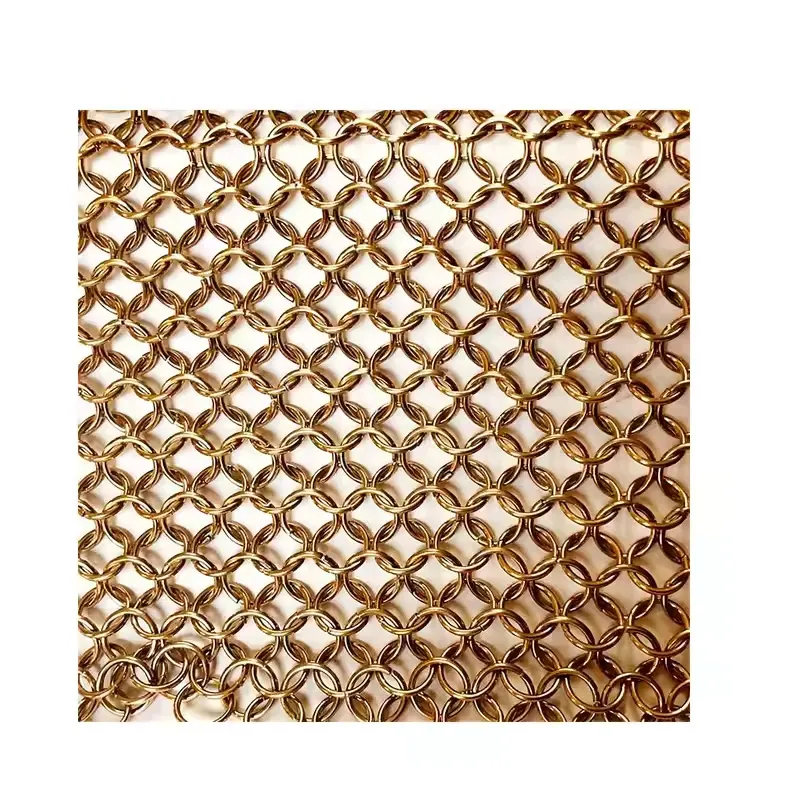

Fig 4: Customization options for ring mesh curtain color and texture.

Tailored Customization Solutions by Jinjiu Wire Mesh

At Jinjiu, we understand that every project is unique. Our expertise as a leading ring mesh curtain factory allows us to offer extensive customization options, ensuring that our products seamlessly integrate with your vision and functional requirements.

- Material & Alloy Customization: From standard SUS 304/316 stainless steel for general applications to specialized alloys for extreme environments (e.g., high-salinity coastal areas, chemical plants for anti-corrosion), we advise and provide the optimal material.

- Dimensions & Weave Patterns: We can produce curtains of virtually any width and height, tailored to your exact architectural dimensions. While the standard four-in-one link is common, we can explore variations in weave density to achieve specific transparency or light diffusion effects.

- Color & Finish Variety: Beyond natural metal finishes, we offer a palette of colors through anodizing for aluminum or PVD coating/powder coating for stainless steel, allowing for complete design integration.

- Edge Treatment & Installation Systems: We provide custom edge treatments and integrate specialized hanging systems (e.g., rod pocket, track systems, eyelets) to facilitate seamless and secure installation, engineered to your project's specific needs.

- Logo & Pattern Integration: For branding or unique aesthetic requirements, it is possible to integrate custom patterns or logos into the mesh design, creating a truly bespoke element.

Our dedicated engineering team collaborates closely with architects, designers, and contractors from concept to completion, ensuring that every customized ring mesh curtain solution not only meets but exceeds expectations.

Real-World Application Cases & Client Feedback

The practical application of ring mesh curtain spans a multitude of successful projects worldwide, demonstrating its adaptability and performance. Our clients, ranging from renowned architectural firms to leading hospitality groups and industrial corporations, consistently commend the transformative impact of our products.

Fig 5: A grand building facade incorporating ring mesh curtain for solar shading and aesthetics.

Case Study Snippets:

- Luxury Hotel Lobby (Dubai): A leading hospitality client required a striking yet functional partition for their hotel lobby to separate the lounge area from the reception. Our custom-designed, bronze-anodized aluminum ring mesh curtain provided a shimmering, semi-transparent divider that allowed light to pass through while creating an intimate ambiance. The client praised its elegant aesthetic and ease of maintenance, noting, "The curtain transformed our lobby, adding a touch of modern luxury while maintaining an open feel."

- Corporate Office Atrium (New York): For a Fortune 500 company's headquarters, a large metal ring mesh curtain was installed in the central atrium as a decorative ceiling feature and a subtle acoustic dampener. The stainless steel mesh, polished to a high sheen, reflected natural light, illuminating the space and creating a dynamic visual effect. The facilities manager reported improved light distribution and a more inviting atmosphere for employees.

- Museum Exhibition Space (London): A prestigious museum utilized ring mesh curtain as flexible backdrops for temporary art exhibitions. The material's neutrality and ability to drape elegantly made it an ideal choice for showcasing diverse artworks. The museum curators appreciated its versatility and durability, allowing for frequent reconfigurations without wear and tear.

- Industrial Security Partition (Petrochemical Plant, Saudi Arabia): In a demanding industrial environment, a robust stainless steel ring mesh curtain was used as a lightweight, non-corrosive security barrier around sensitive equipment. Its high tensile strength and resistance to harsh chemicals ensured long-term safety and minimal operational disruption, showcasing its value beyond mere aesthetics.

These diverse applications underscore the versatility and inherent value of ring mesh curtain solutions provided by a trusted ring mesh curtain exporter like Jinjiu Wire Mesh. Our commitment to excellence is reflected in the success of our clients' projects and their continued trust in our products.

Fig 6: Ring mesh curtain used in an industrial setting for safety and environmental separation.

Ensuring Trustworthiness: FAQ, Delivery, Warranty, and Support

Building long-term relationships with clients is founded on transparency, reliability, and robust support systems. As a leading ring mesh curtain factory and exporter, Jinjiu Wire Mesh prioritizes client satisfaction through clear communication, comprehensive service, and unwavering commitment to quality.

Frequently Asked Questions (FAQ) about Ring Mesh Curtain

1. What materials are available for ring mesh curtain?

We primarily offer ring mesh curtain in high-grade stainless steel (SUS 304, 316, 316L) due to its excellent durability and corrosion resistance. Aluminum alloy is also available for lighter weight and color anodizing options, and carbon steel can be used for specific industrial applications where cost-effectiveness and certain finishes are prioritized. The choice of material largely depends on the specific application environment and desired aesthetic.

2. How is the ring mesh curtain installed?

Ring mesh curtain is typically installed using various hanging systems tailored to the application. Common methods include track systems with rollers (allowing the curtain to slide), rod pocket installations (for fixed or gathered drapes), or direct attachment via hooks/eyelets to a frame. We provide detailed installation guides and can offer customized mounting hardware solutions engineered to your project's structural requirements, ensuring secure and aesthetically pleasing integration.

3. Can the ring mesh curtain be customized in terms of color and size?

Absolutely. Customization is a cornerstone of our service. We can produce ring mesh curtain in virtually any size required for your project. For color, stainless steel can be PVD coated in various hues (e.g., gold, rose gold, black), while aluminum mesh can be anodized in a wide range of colors. We can also provide powder coating services for specific RAL colors, allowing for complete design flexibility.

4. What is the expected lifespan of a metal ring mesh curtain?

When properly selected and installed, a metal ring mesh curtain, particularly those made from high-grade stainless steel, boasts an exceptionally long service life. In typical architectural applications, an outdoor stainless steel mesh curtain can last well over 20 years, while indoor applications can easily exceed 30-40 years with minimal maintenance. Its inherent resistance to rust, UV degradation, and environmental factors contributes to this longevity.

5. Is ring mesh curtain suitable for outdoor use?

Yes, our ring mesh curtain, especially those made from SUS 316 or 316L stainless steel, is highly suitable for outdoor applications. These materials offer superior corrosion resistance, particularly in environments exposed to moisture, salt, or industrial pollutants. They are also highly resistant to UV degradation, ensuring their aesthetic and structural integrity is maintained over decades in exterior settings like building facades or sunscreens.

6. How does ring mesh curtain contribute to sustainable building?

Ring mesh curtain contributes to sustainable building in several ways. Firstly, its open structure allows for natural light penetration and improved ventilation, reducing the reliance on artificial lighting and air conditioning, thereby cutting energy consumption. Secondly, metal meshes are durable, long-lasting, and often made from recycled content. At the end of their long life, they are fully recyclable, minimizing waste and promoting a circular economy in construction. This aligns with LEED and other green building certifications.

7. What are the maintenance requirements for ring mesh curtain?

One of the significant advantages of ring mesh curtain is its low maintenance. For most applications, occasional cleaning with water and a mild detergent is sufficient to remove dust or accumulated debris. For outdoor installations, natural rainfall often provides adequate cleaning. Avoid harsh chemicals or abrasive tools that could damage the finish. Our team can provide specific cleaning guidelines based on the material and finish of your curtain.

Delivery Cycle and Logistics

As an experienced ring mesh curtain exporter, we understand the importance of timely delivery for project success. Our streamlined production process, combined with robust logistics partnerships, enables us to offer efficient delivery schedules.

Typical Production Lead Time: For standard orders, lead times usually range from 2-4 weeks, depending on the volume and customization complexity. Large or highly custom projects may require longer, which will be communicated clearly during the quotation phase.

Shipping: We utilize reliable global freight carriers (sea, air, and express services) to ensure your ring mesh curtain reaches your site securely and on schedule. All shipments are meticulously packaged to prevent damage during transit. We provide tracking information and dedicated logistics support to keep you informed every step of the way.

Quality Assurance and Warranty Commitment

At Jinjiu Wire Mesh, our commitment to quality is unwavering. Every ring mesh curtain leaving our factory undergoes rigorous multi-stage quality control inspections, adhering to international standards such as ISO 9001:2015. We offer a comprehensive warranty on our products, covering manufacturing defects and material integrity for a specified period (typically 5-10 years, depending on product type and application). This warranty underscores our confidence in the durability and craftsmanship of our metal ring mesh curtain solutions. Our professional customer support team is always available to address any post-purchase queries or concerns, ensuring a seamless and satisfying experience.

References and Further Reading