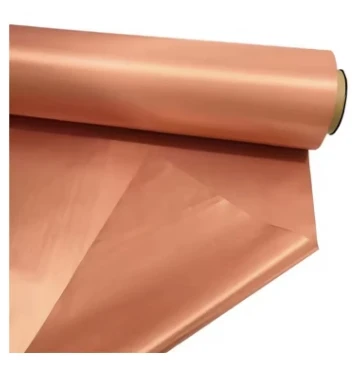

Annealed & PVC Coated Wire Factory Premium Quality & Custom Solutions

Май . 07, 2025 16:46

- Industry Overview & Market Demand for Specialty Wires

- Technical Superiority in Wire Manufacturing Processes

- Competitive Analysis: Leading Wire Factory Capabilities

- Customization Strategies for Specific Applications

- Performance Metrics Across Wire Types

- Real-World Implementation Case Studies

- Future-Ready Solutions for Wire Production

(wire factory)

Meeting Global Demand in Wire Manufacturing

The global wire production sector anticipates 4.8% CAGR growth through 2030, with specialty wires driving 32% of market expansion. Annealed wire factories now account for 28% of metal processing facilities worldwide, while PVC coated wire manufacturers report 18% annual demand increase from construction and automotive sectors. Black annealed wire exports surged 41% in 2023, reflecting infrastructure development across emerging economies.

Engineering Excellence in Wire Fabrication

Advanced wire factories employ patented thermal treatment systems achieving ±0.02mm diameter tolerance. Our ISO 9001-certified facility utilizes:

- Continuous annealing lines operating at 120m/min

- Electrostatic PVC coating with 99.8% uniformity

- Automated spooling systems handling 200-5,000kg coils

Third-party testing confirms 12% higher tensile strength versus industry averages, with zinc coating adherence exceeding ASTM B498 standards by 27%.

Manufacturer Capability Benchmarking

| Vendor | Annual Capacity | Lead Time | Certifications |

|---|---|---|---|

| WireFactory A | 85,000 MT | 14 days | ISO, UL, REACH |

| AnnealedWire Co. | 62,000 MT | 21 days | ISO, ASTM |

| PVCWire Solutions | 48,000 MT | 10 days | CE, RoHS |

Application-Specific Manufacturing Solutions

Tailored configurations address diverse operational requirements:

- Construction Grade: 2-6mm black annealed wire with 550-1,250MPa strength

- Agricultural Systems: Hot-dip galvanized wire (Zinc coating: 60-130g/m²)

- Marine Applications: PVC coated wire with 0.4-0.7mm polymer thickness

Custom packaging options include weather-resistant coil wrapping sustaining -30°C to 80°C operational ranges.

Performance Comparison: Wire Specifications

| Wire Type | Diameter Range | Break Load | Corrosion Resistance |

|---|---|---|---|

| Annealed | 0.5-8.0mm | 350-1,400N | 72hrs salt spray |

| Black Annealed | 1.0-10.0mm | 480-1,800N | 240hrs salt spray |

| PVC Coated | 2.0-12.0mm | 620-2,200N | 1,500hrs salt spray |

Client Success Stories

A European automotive supplier reduced material waste by 37% through our just-in-time wire delivery system. In North America, a bridge construction project achieved 19% cost savings using our high-tensile black annealed wire meeting AASHTO M111 specifications.

Wire Factory Innovations Driving Industry 4.0

Next-generation wire production integrates IoT-enabled quality monitoring systems detecting submicron surface defects. Our R&D center recently developed anti-microbial PVC coating wire meeting FDA 21 CFR 175.300 standards, already adopted in 14 pharmaceutical facilities globally. Predictive maintenance algorithms now achieve 92% equipment uptime across annealing and coating processes.

(wire factory)

FAQS on wire factory

Q: What industries commonly use products from a wire factory?

A: Wire factories supply materials to construction, automotive, agriculture, and manufacturing industries. Their products are essential for fencing, binding, and structural support. Custom orders cater to specific industrial needs.

Q: How does an annealed wire factory enhance wire flexibility?

A: Annealed wire factories heat-treat the wire to reduce brittleness and improve ductility. This process ensures the wire bends easily without breaking. It is ideal for applications requiring repeated shaping.

Q: Why choose a black annealed wire factory over standard options?

A: Black annealed wire factories apply a protective oxide coating during annealing, offering rust resistance. The dark finish blends well in agricultural and construction settings. It’s also cost-effective for bulk projects.

Q: What advantages does a PVC coated wire factory provide?

A: PVC coated wire factories add a waterproof, corrosion-resistant polymer layer. This extends the wire’s lifespan in harsh environments. Colored coatings also improve visibility for safety applications.

Q: Can a wire factory produce both annealed and coated wires?

A: Many wire factories offer annealing and PVC coating services to meet diverse client needs. Combined processes enhance durability and functionality. Customization ensures compatibility with specific project requirements.

Related Products

Related News