FAQS

Brass Woven Mesh FAQ

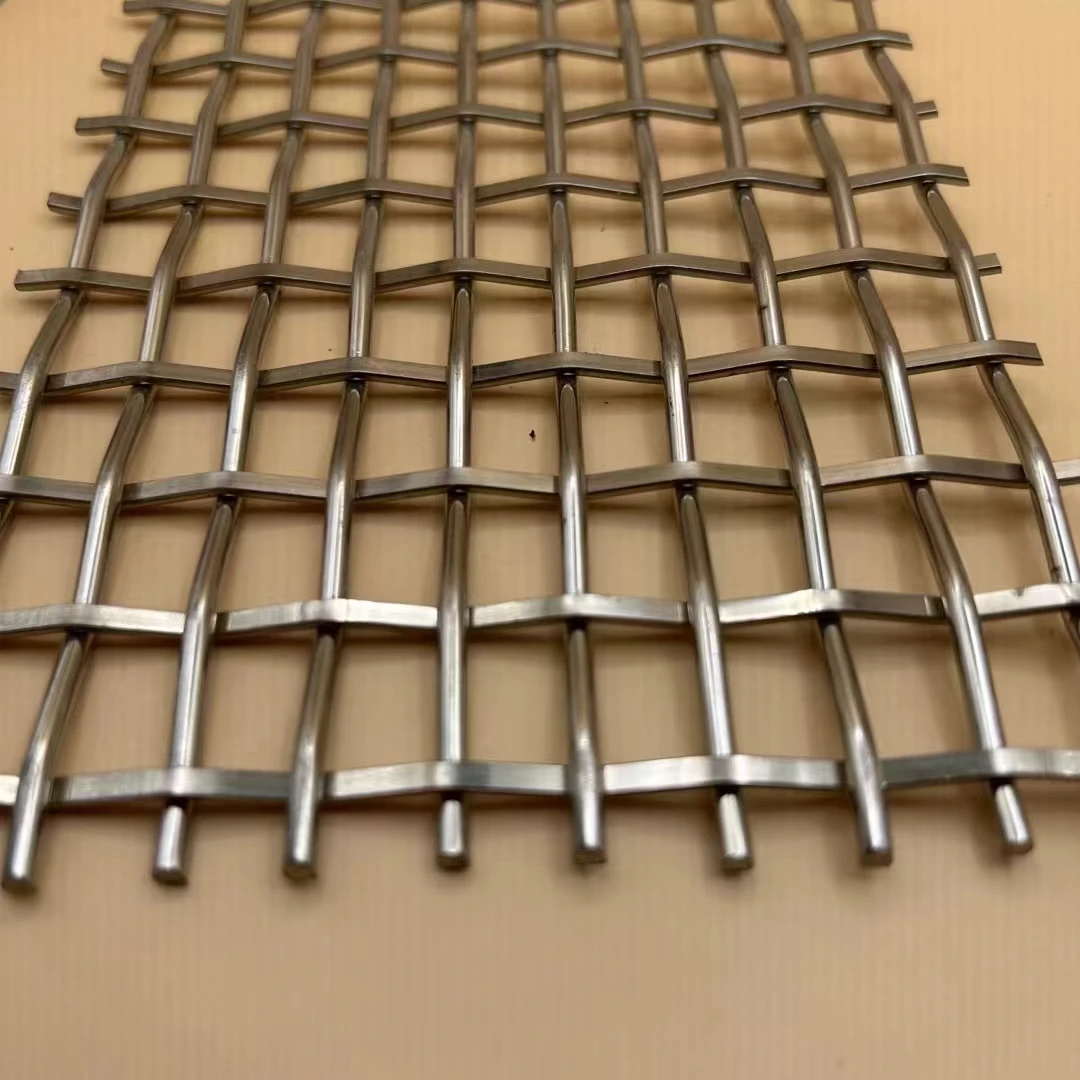

What are the application scenarios of brass woven mesh?

The use of brass woven mesh in industrial environments for filtration and separation processes can effectively filter particles and allow liquids or gases to pass through; Used for decorative screens, railings, and facades in architectural applications; In jewelry and craft projects, it is also highly favored for its aesthetic quality.

How to maintain brass woven wire mesh?

Brass woven wire mesh should be kept clean and free of debris, and regularly dusted or wiped with a soft cloth to prevent loss of luster. If it loses its luster, it can be cleaned with a mild brass cleaner or a mixture of vinegar and baking soda. Avoid using abrasive materials to scratch the surface. For outdoor applications, consider applying protective coatings to improve durability and prevent corrosion.

What are the advantages of copper woven wire mesh compared to other materials?

Compared with ordinary metal woven mesh, copper woven wire mesh has stronger corrosion resistance and can be used for a long time in humid environments; Compared to plastic woven mesh, it is more durable and has a unique metallic texture and color, which performs better in decorative aspects and enhances overall aesthetics.

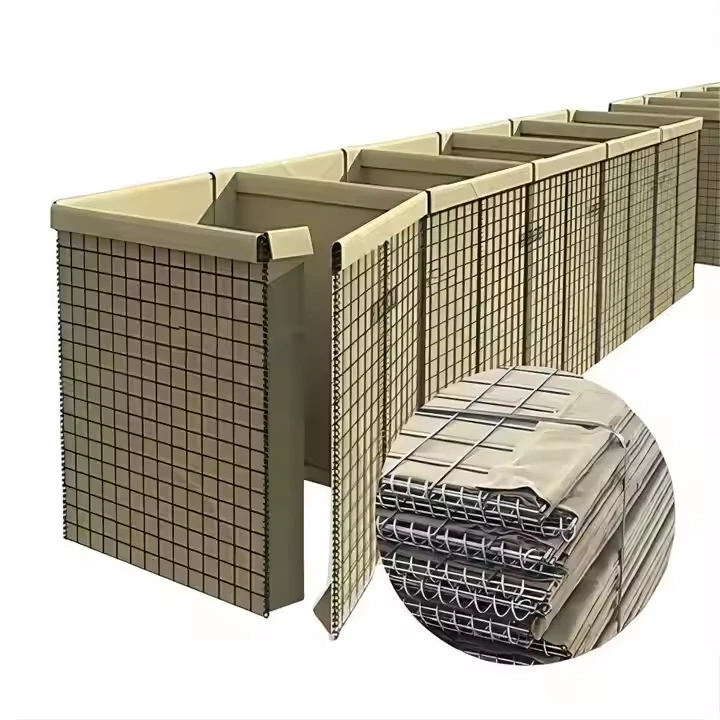

Can your company provide services for customizing decorative brass mesh screen with special specifications?

We are committed to providing customers with high-quality products and services. For customized decorative brass mesh screen with special specifications, we have a professional team and rich experience. We will evaluate and produce according to your specific requirements to meet your personalized needs in the project.

Related Products

Related News

We can customized wire mesh products

by your drawing and requirements