Hesco Barrier

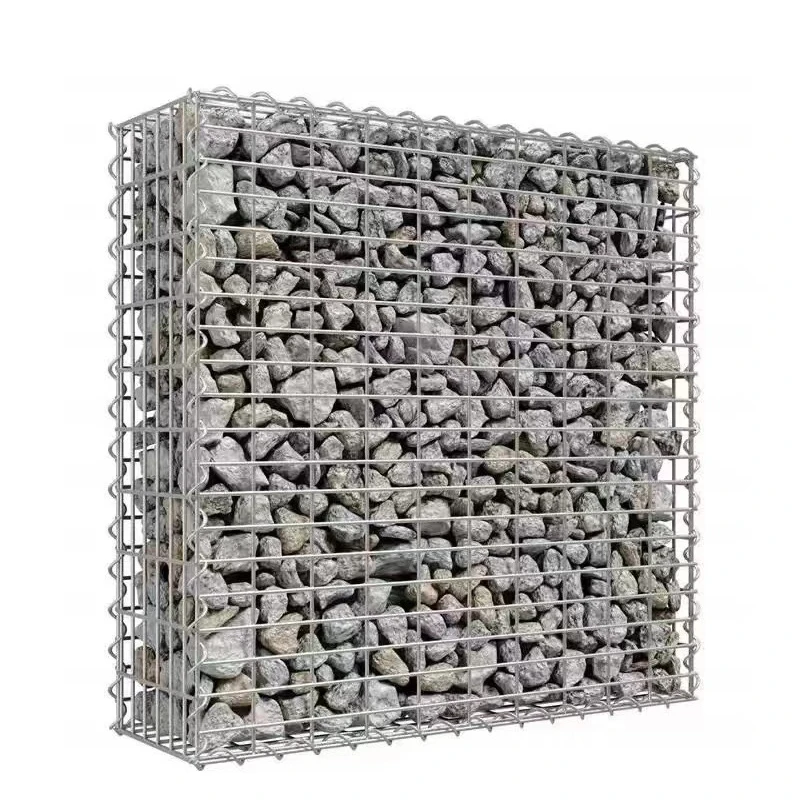

The explosion-proof cage, also known as explosion-proof wall or explosion-proof net, also known as Hesco barrier or Hesco fortress, is an important form of protection in modern warfare and flood control. In actual use, it forms a solid wire mesh protective wall by filling stones, sand or soil in the mesh cage. Due to its recommended installation, foldable and easy operation, it is applied in modern warfare.

|

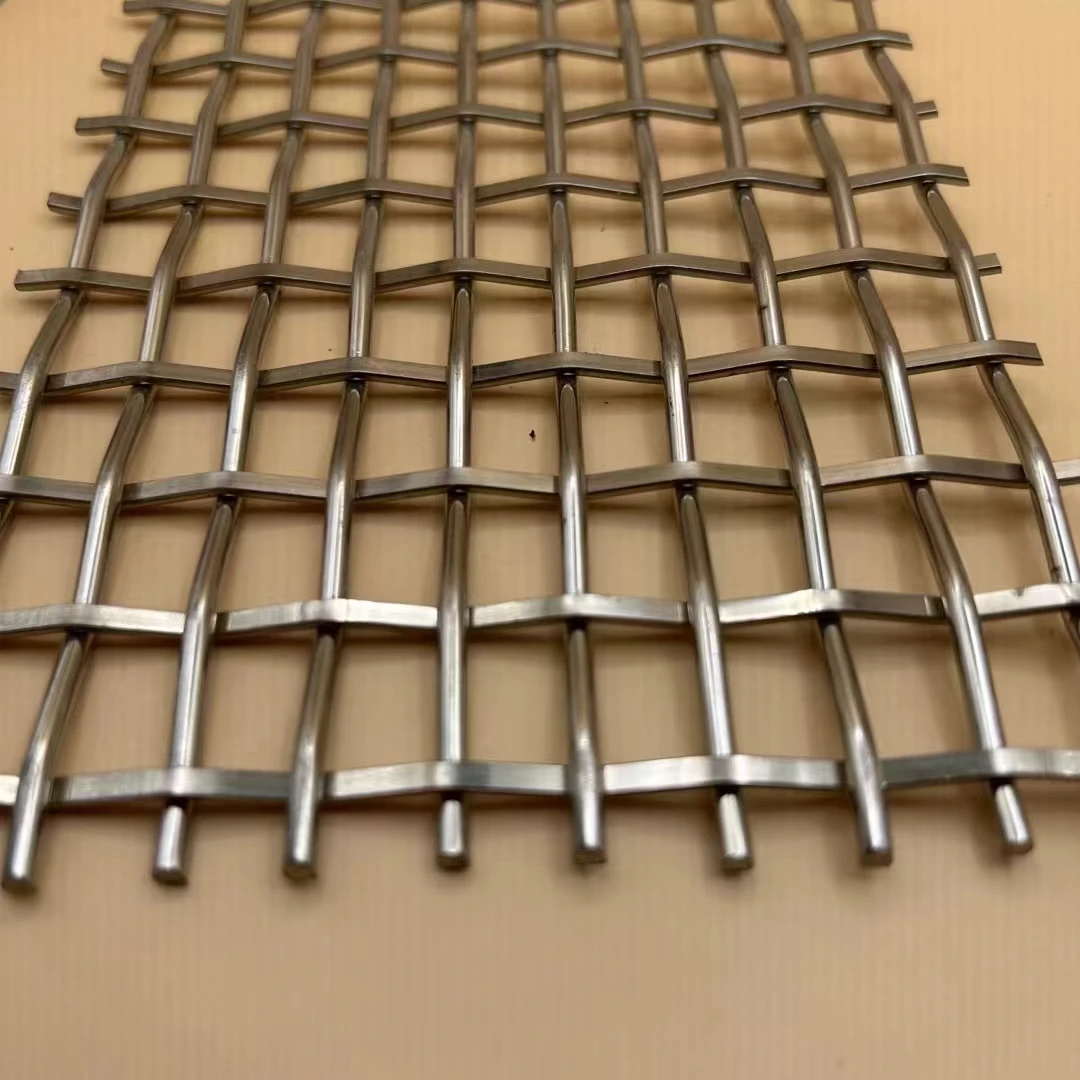

Mesh wire diameter

|

3mm,4mm,5mm,6mm etc

|

|

Spring wire diameter

|

3mm,4mm,5mm,6mm etc

|

|

Mesh size

|

50*50mm,50*100mm,37.5*100mm,60*60mm,65*65mm,70*70mm,76*76mm,80*80mm or

as your request.

|

|

Panel Size

|

0.61*0.61m,1*1m,1.2*1.2m,1.5*1.5m,1.5*2m,2*2m, 2.21*2.13m or as your request.

|

|

Finish

|

Electro galvanized after welded

Hot dipped galvanized welded

Galfan coated after welded

|

|

Geotextile

|

Heavy duty non-woven polypropylene

|

|

Packing

|

Wrapped with shrink film or packed in pallet

|

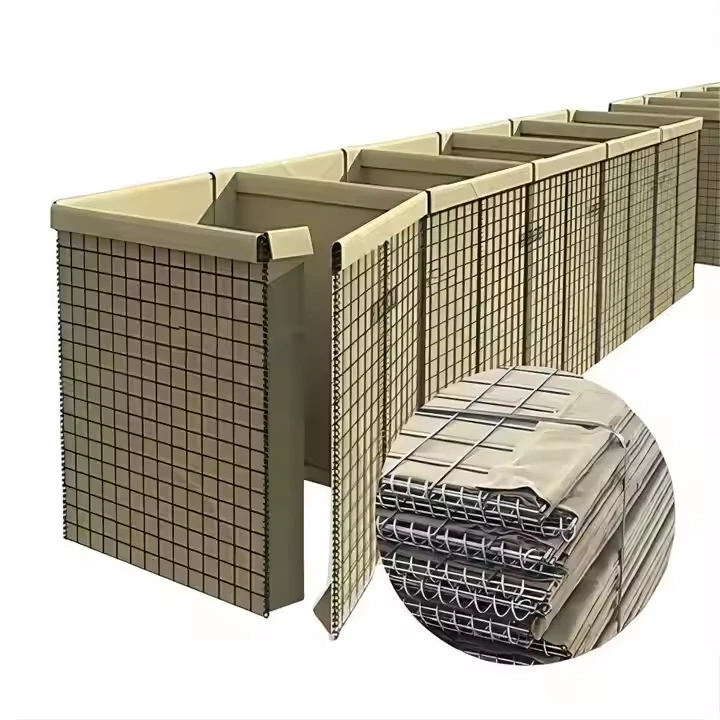

A defensive barrier / defensive barrier is a modern type of gabion used for defense and flood protection. It is made of a collapsible wire mesh container and a heavy-duty fabric lining and can be used as a single unit or multiple units connected together

Packaging Detail

Wrapped with shrink film or packed in pallet.5-10 units on the pallet.

Application

1)Perimeter Security and Defence Walls

2) Protecting Existing Structures

3) Explosives and Contraband Search Areas

4) Protection engineering of seaside area

5)Defensive Firing Positions

6)Flood control retaining wall

Introducing our premium Hesco barriers, expertly designed to provide superior protection and fortification for various applications, from military use to construction sites and emergency response scenarios. Our barriers are constructed using high-quality, durable materials that ensure long-lasting performance and reliability even in the most demanding environments. Each Hesco barrier features a robust welded wire mesh structure, filled with non-woven geotextile fabric, which allows for exceptional strength and stability.

The unique design of our barriers offers easy deployment, allowing for rapid setup in critical situations where time is of the essence. The versatility of our Hesco barriers makes them ideal for flood control, containment of hazardous materials, and providing a secure perimeter around sensitive areas. They also boast the ability to withstand adverse weather conditions, ensuring your fortifications remain intact through storms, floods, or high winds. Each barrier is engineered to absorb impact effectively, making them a reliable choice for military operations and civil engineering projects alike.

With a focus on safety, our Hesco barriers are designed to meet stringent industry standards, providing peace of mind to users by ensuring maximum protection. Innovatively designed for modularity and adaptability, our barriers can easily be linked together to create larger configurations as needed, making them an essential tool for any construction or emergency preparedness team. Invest in the quality and durability of our Hesco barriers for unparalleled protection and peace of mind. Whether you are safeguarding a construction site, preparing for natural disasters, or establishing secure military encampments, trust our Hesco barriers to deliver the reliable performance you need. Choose our industry-leading Hesco barriers today and fortify your defenses with confidence.

Defensive Barrier Specifications: Mesh Sizes, Panel Dimensions & Coatings

At the core of effective defensive barriers lies precision in design—and Hesco barriers excel here, with specifications engineered for reliability in military, flood control, and industrial security. As a leading provider, JINJIU ensures every detail of these defence barrier systems—from mesh weave to coating thickness—aligns with high-stakes operational demands.

Mesh sizes are critical for structural integrity. Hesco barriers feature double-twisted hexagonal mesh, with standard openings ranging from 2.5×5cm to 5×10cm. The 2.5×5cm mesh, ideal for military defence barrier setups, prevents fine aggregate (like sand or gravel) from escaping when filled, ensuring the barrier retains shape under impact. For flood control or perimeter security, 5×10cm mesh balances strength with drainage, allowing water to pass while trapping larger fill materials (rock, concrete blocks) to reinforce the structure. All meshes use high-tensile steel wire (2.5-4.0mm diameter), resistant to cutting or deformation.

Panel dimensions cater to rapid deployment and scalability. Standard panels come in lengths of 1m, 3m, and 6m, with heights ranging from 0.5m to 3m—flexible enough for everything from temporary roadblocks to permanent border fortifications. The 3m×1m panel is a workhorse: lightweight (15-20kg) for quick manual installation, yet robust enough to form a 1m-high defensive barrier when filled. For larger projects, 6m×2m panels reduce assembly time, as fewer units cover more ground, while 0.5m-high variants suit low-profile security zones like industrial yards.

Coatings enhance durability across environments. Galvanized coatings (80-120g/m² zinc) are standard, protecting against rust in humid or coastal areas—vital for defensive barriers deployed long-term. For extreme conditions (chemical exposure, saltwater), PVC coatings (0.2-0.5mm thick) add a secondary layer, extending service life to 15+ years. These coatings adhere seamlessly to the mesh, ensuring no weak points where corrosion could start.

JINJIU’s Hesco barriers marry these specifications to purpose: tight 2.5×5cm mesh for military defence barrier resilience, 6m panels for rapid flood response, and dual coatings for all-weather reliability. Each component works in tandem, proving that in defensive barriers, precision isn’t just a detail—it’s the foundation of security.

The Science of Strength: What Makes Defensive Barriers Withstand Impact

Behind every defensive barrier that repels collisions, blasts, or forced entry lies a deliberate blend of material science and structural engineering. JINJIU’s defence barrier systems are engineered to turn impact energy into manageable force, ensuring they stand firm in military operations, riot control, and critical infrastructure protection.

Material selection is the first line of defense. High-tensile steel—with a minimum yield strength of 350MPa—forms the core of these defensive barriers. This steel undergoes cold working, aligning its molecular structure to resist deformation; even under 10,000N of force (equivalent to a 2-ton vehicle impact at 10km/h), the metal bends minimally before returning to shape. For coastal or corrosive environments, galvanized coatings (120g/m² zinc) add a protective layer, ensuring strength isn’t compromised by rust over time.

Structural design amplifies impact resistance. Modular panels with interlocking joints distribute force evenly across the defence barrier system, preventing localized failure. For example, 3m-wide panels connect via steel pins that absorb 30% of impact energy through controlled flexing, while reinforced edges (6mm steel plating) resist puncturing. When filled with aggregate (rock, concrete), the barrier’s mass acts as a kinetic buffer—slowing intruders or debris by converting motion into friction between fill materials.

Testing validates real-world performance. JINJIU’s defensive barriers undergo rigorous trials: 50km/h vehicle impact tests (mimicking ramming attempts), blast simulation (up to 5kg TNT equivalent), and cyclic load testing (10,000+ repetitions of 5kN force). These tests ensure the barrier retains 90% structural integrity post-impact, a critical metric for military defence barrier applications where failure isn’t an option.

Whether stopping a speeding vehicle at a checkpoint or shielding a facility from debris during a storm, the science is clear: strength comes from intentional design. JINJIU’s defensive barriers don’t just resist impact—they outsmart it, turning force into a testament to engineering excellence.