Kizuizi cha Hesco

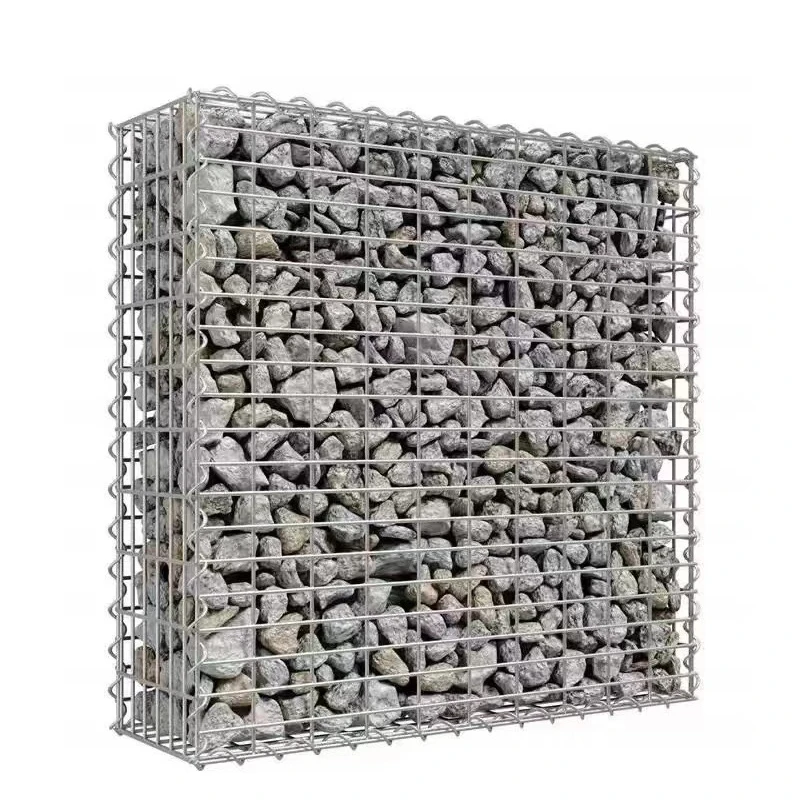

Ngome ya kuzuia mlipuko, pia inajulikana kama ukuta usioweza kulipuka au chandarua kisichoweza kulipuka, pia kinajulikana kama kizuizi cha Hesco au ngome ya Hesco, ni njia muhimu ya ulinzi katika vita vya kisasa na udhibiti wa mafuriko. Katika matumizi halisi, huunda ukuta wa ulinzi wa matundu ya waya kwa kujaza mawe, mchanga au udongo kwenye ngome ya matundu. Kwa sababu ya usakinishaji wake uliopendekezwa, ufanyaji kazi wa kukunjwa na rahisi, unatumika katika vita vya kisasa.

|

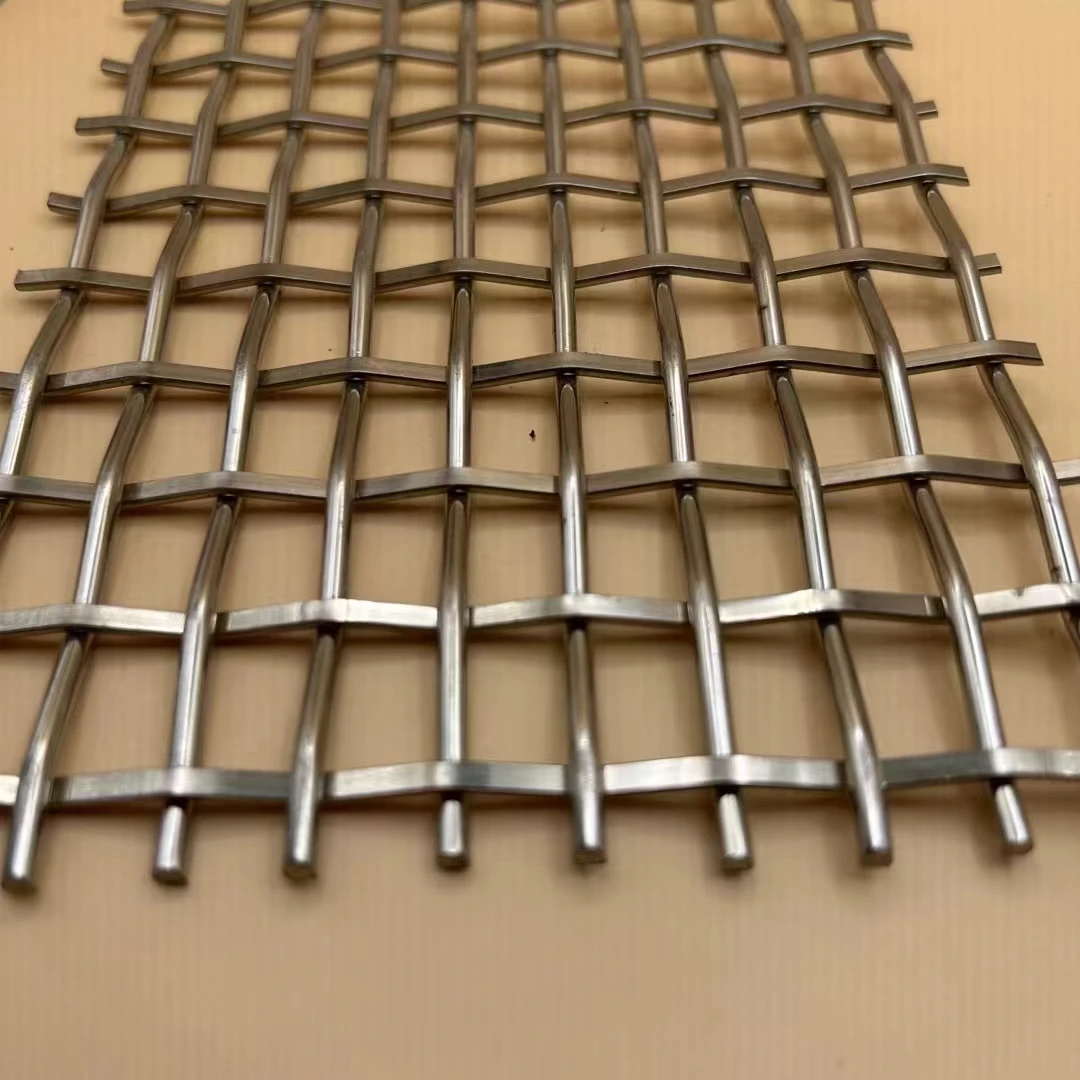

Kipenyo cha waya wa matundu

|

3mm,4mm,5mm,6mm n.k

|

|

Kipenyo cha waya wa spring

|

3mm,4mm,5mm,6mm n.k

|

|

Ukubwa wa matundu

|

50*50mm,50*100mm,37.5*100mm,60*60mm,65*65mm,70*70mm,76*76mm,80*80mm au

kama ombi lako.

|

|

Ukubwa wa Paneli

|

0.61*0.61m,1*1m,1.2*1.2m,1.5*1.5m,1.5*2m,2*2m, 2.21*2.13m au kama ombi lako.

|

|

Maliza

|

Electro mabati baada ya kulehemu

Moto limelowekwa mabati svetsade

Galfan coated baada ya svetsade

|

|

Geotextile

|

Wajibu mzito polypropen isiyo ya kusuka

|

|

Ufungashaji

|

Imefungwa na filamu ya kupungua au imefungwa kwenye pallet

|

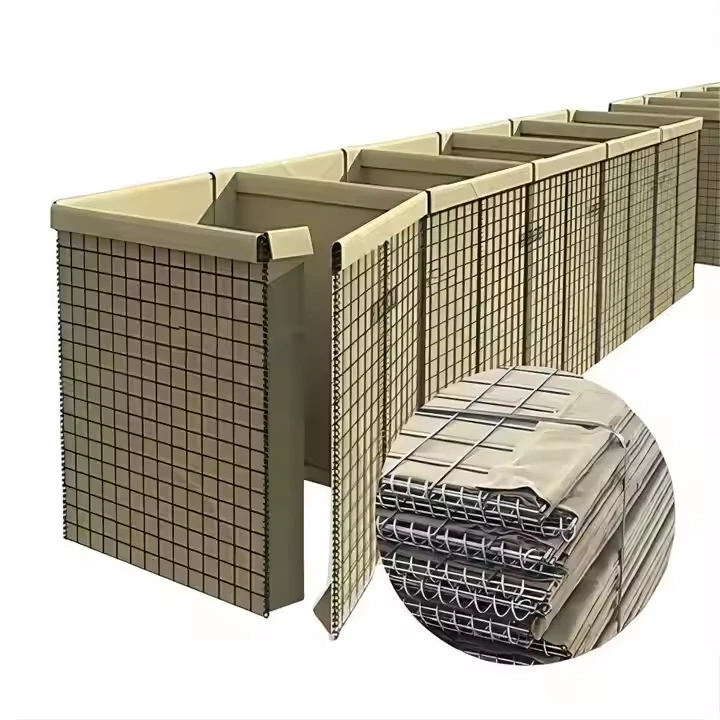

Kizuizi cha ulinzi / kizuizi cha kujihami ni aina ya kisasa ya gabion inayotumika kwa ulinzi na ulinzi wa mafuriko. Imetengenezwa kwa kontena la wavu wa waya linaloweza kukunjwa na kitambaa kizito na inaweza kutumika kama kitengo kimoja au vitengo vingi vilivyounganishwa pamoja.

Maelezo ya Ufungaji

Imefungwa na filamu ya kupungua au imefungwa kwenye pallet.Vitengo 5-10 kwenye pala.

Maombi

1) Kuta za Ulinzi na Usalama wa Mzunguko

2) Kulinda Miundo Iliyopo

3) Vilipuzi na Maeneo ya Utafutaji wa Bidhaa za magendo

4) Uhandisi wa ulinzi wa eneo la bahari

5)Nafasi za Kurusha za Ulinzi

6) Ukuta wa kuzuia mafuriko

Tunakuletea vizuizi vyetu vya kulipia vya Hesco, vilivyoundwa kwa ustadi ili kutoa ulinzi na uimarishaji wa hali ya juu kwa matumizi mbalimbali, kuanzia matumizi ya kijeshi hadi tovuti za ujenzi na hali za kukabiliana na dharura. Vizuizi vyetu vinajengwa kwa kutumia vifaa vya hali ya juu, vya kudumu ambavyo vinahakikisha utendakazi wa kudumu na kutegemewa hata katika mazingira magumu zaidi. Kila kizuizi cha Hesco kina muundo thabiti wa wavu wa waya ulio svetsade, uliojaa kitambaa cha geotextile kisicho na kusuka, ambacho kinaruhusu nguvu na utulivu wa kipekee.

Muundo wa kipekee wa vizuizi vyetu hutoa uwekaji rahisi, kuruhusu usanidi wa haraka katika hali muhimu ambapo wakati ni muhimu. Uwezo mwingi wa vizuizi vyetu vya Hesco huvifanya kuwa bora kwa udhibiti wa mafuriko, kuzuia nyenzo hatari, na kutoa eneo salama kuzunguka maeneo nyeti. Pia wanajivunia uwezo wa kustahimili hali mbaya ya hali ya hewa, wakihakikisha kwamba ngome zako zinabaki bila dhoruba, mafuriko, au upepo mkali. Kila kizuizi kimeundwa ili kunyonya athari kwa ufanisi, na kuifanya kuwa chaguo la kuaminika kwa shughuli za kijeshi na miradi ya uhandisi wa kiraia sawa.

Kwa kuzingatia usalama, vizuizi vyetu vya Hesco vimeundwa ili kukidhi viwango vikali vya sekta, kutoa amani ya akili kwa watumiaji kwa kuhakikisha ulinzi wa juu zaidi. Iliyoundwa kwa ubunifu kwa ubadilikaji na ubadilikaji, vizuizi vyetu vinaweza kuunganishwa kwa urahisi ili kuunda usanidi mkubwa zaidi inavyohitajika, na kuifanya kuwa zana muhimu kwa timu yoyote ya ujenzi au maandalizi ya dharura. Wekeza katika ubora na uimara wa vizuizi vyetu vya Hesco kwa ulinzi usio na kifani na amani ya akili. Iwe unalinda tovuti ya ujenzi, unajitayarisha kwa ajili ya majanga ya asili, au unaanzisha kambi salama za kijeshi, amini vizuizi vyetu vya Hesco kukupa utendaji unaotegemewa unaohitaji. Chagua vizuizi vyetu vya Hesco vinavyoongoza katika tasnia leo na uimarishe ulinzi wako kwa kujiamini.

Defensive Barrier Specifications: Mesh Sizes, Panel Dimensions & Coatings

At the core of effective defensive barriers lies precision in design—and Hesco barriers excel here, with specifications engineered for reliability in military, flood control, and industrial security. As a leading provider, JINJIU ensures every detail of these defence barrier systems—from mesh weave to coating thickness—aligns with high-stakes operational demands.

Mesh sizes are critical for structural integrity. Hesco barriers feature double-twisted hexagonal mesh, with standard openings ranging from 2.5×5cm to 5×10cm. The 2.5×5cm mesh, ideal for military defence barrier setups, prevents fine aggregate (like sand or gravel) from escaping when filled, ensuring the barrier retains shape under impact. For flood control or perimeter security, 5×10cm mesh balances strength with drainage, allowing water to pass while trapping larger fill materials (rock, concrete blocks) to reinforce the structure. All meshes use high-tensile steel wire (2.5-4.0mm diameter), resistant to cutting or deformation.

Panel dimensions cater to rapid deployment and scalability. Standard panels come in lengths of 1m, 3m, and 6m, with heights ranging from 0.5m to 3m—flexible enough for everything from temporary roadblocks to permanent border fortifications. The 3m×1m panel is a workhorse: lightweight (15-20kg) for quick manual installation, yet robust enough to form a 1m-high defensive barrier when filled. For larger projects, 6m×2m panels reduce assembly time, as fewer units cover more ground, while 0.5m-high variants suit low-profile security zones like industrial yards.

Coatings enhance durability across environments. Galvanized coatings (80-120g/m² zinc) are standard, protecting against rust in humid or coastal areas—vital for defensive barriers deployed long-term. For extreme conditions (chemical exposure, saltwater), PVC coatings (0.2-0.5mm thick) add a secondary layer, extending service life to 15+ years. These coatings adhere seamlessly to the mesh, ensuring no weak points where corrosion could start.

JINJIU’s Hesco barriers marry these specifications to purpose: tight 2.5×5cm mesh for military defence barrier resilience, 6m panels for rapid flood response, and dual coatings for all-weather reliability. Each component works in tandem, proving that in defensive barriers, precision isn’t just a detail—it’s the foundation of security.

The Science of Strength: What Makes Defensive Barriers Withstand Impact

Behind every defensive barrier that repels collisions, blasts, or forced entry lies a deliberate blend of material science and structural engineering. JINJIU’s defence barrier systems are engineered to turn impact energy into manageable force, ensuring they stand firm in military operations, riot control, and critical infrastructure protection.

Material selection is the first line of defense. High-tensile steel—with a minimum yield strength of 350MPa—forms the core of these defensive barriers. This steel undergoes cold working, aligning its molecular structure to resist deformation; even under 10,000N of force (equivalent to a 2-ton vehicle impact at 10km/h), the metal bends minimally before returning to shape. For coastal or corrosive environments, galvanized coatings (120g/m² zinc) add a protective layer, ensuring strength isn’t compromised by rust over time.

Structural design amplifies impact resistance. Modular panels with interlocking joints distribute force evenly across the defence barrier system, preventing localized failure. For example, 3m-wide panels connect via steel pins that absorb 30% of impact energy through controlled flexing, while reinforced edges (6mm steel plating) resist puncturing. When filled with aggregate (rock, concrete), the barrier’s mass acts as a kinetic buffer—slowing intruders or debris by converting motion into friction between fill materials.

Testing validates real-world performance. JINJIU’s defensive barriers undergo rigorous trials: 50km/h vehicle impact tests (mimicking ramming attempts), blast simulation (up to 5kg TNT equivalent), and cyclic load testing (10,000+ repetitions of 5kN force). These tests ensure the barrier retains 90% structural integrity post-impact, a critical metric for military defence barrier applications where failure isn’t an option.

Whether stopping a speeding vehicle at a checkpoint or shielding a facility from debris during a storm, the science is clear: strength comes from intentional design. JINJIU’s defensive barriers don’t just resist impact—they outsmart it, turning force into a testament to engineering excellence.