Utangulizi wa Square Wire Mesh

Katika mazingira yanayoendelea kubadilika ya ujenzi, utengenezaji, na matumizi mbalimbali ya viwandani, mahitaji ya nyenzo za kuaminika na zinazoweza kutumika nyingi ni muhimu. Kati ya nyenzo hizi, Square Wire Mesh inajitokeza kama chaguo linalopendekezwa katika sekta nyingi. Kwa sifa zake za kipekee na matumizi mbalimbali, Square Wire Mesh imepata umaarufu katika nchi kote ulimwenguni, kutokana na ubora wake wa kipekee, teknolojia ya hali ya juu, na faida nyingi.

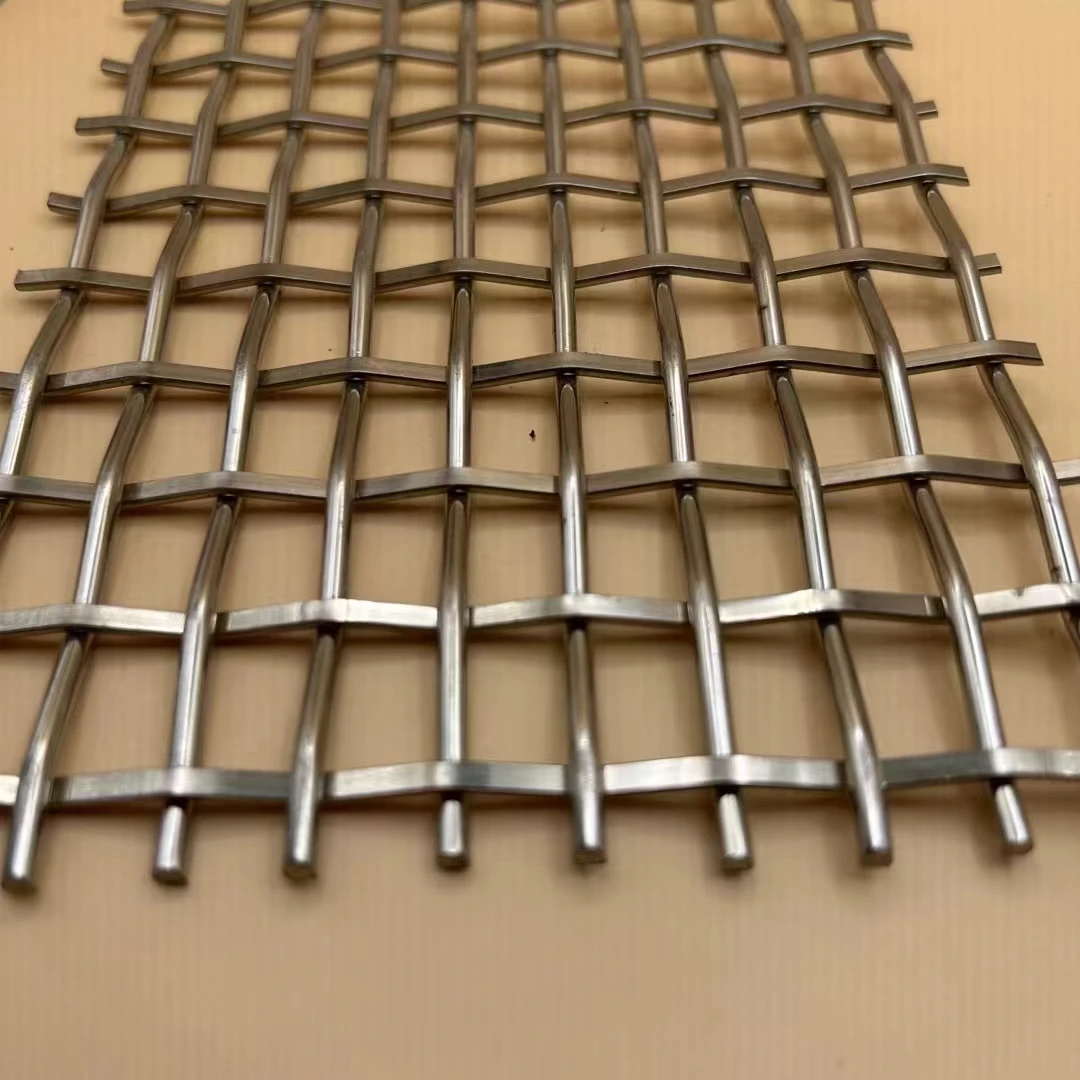

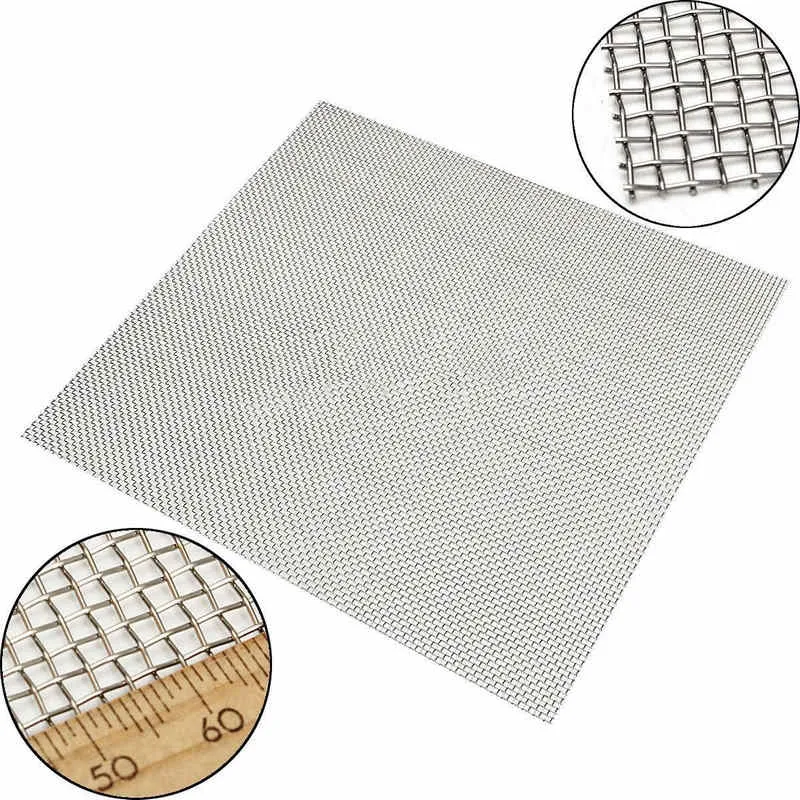

Matundu ya Waya ya Mraba ni aina ya matundu ya waya yaliyofumwa yenye umbo la mraba. Kwa kawaida hutengenezwa kutoka kwa chuma cha hali ya juu, chuma cha pua, au vifaa vingine vya kudumu, vinavyohakikisha uimara na maisha marefu. Mesh hutolewa kupitia mchakato wa kusuka ambao huunda muundo unaofanana na gridi ya taifa, na kuifanya iwe ya kufaa kwa matumizi mbalimbali, kutoka kwa ujenzi hadi kilimo.

Maelezo ya Bidhaa

1.Material: AISI302, 304,316,316L,310S,410,430,904L,2205,2507,etc

2.Wire Diameter: 0.015-2.8mm

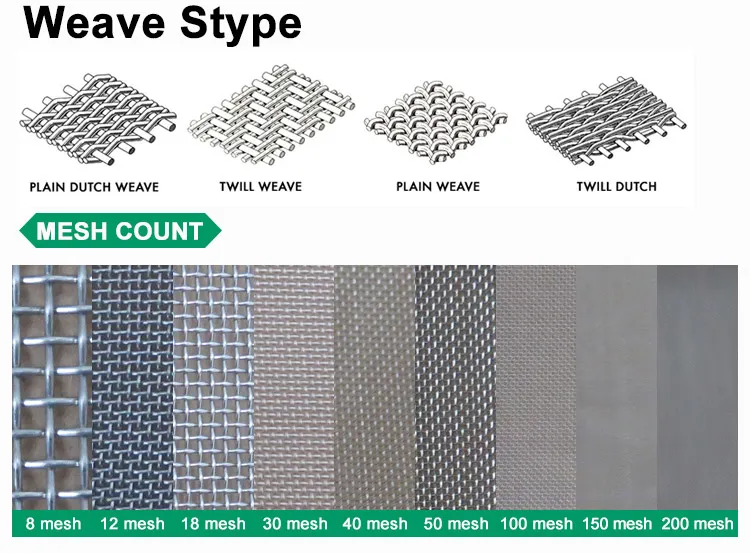

3. Idadi ya matundu:

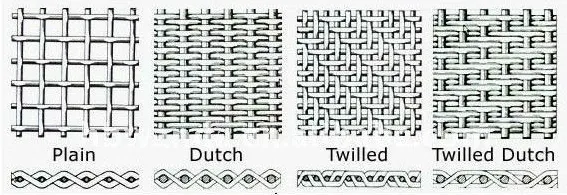

Plain weave can be woven up to 400 mesh.

Twill weave can be woven from 400 to 635mesh.

Dutch weave can be woven up to 3500mesh

- Mchoro wa weave:

Weave Wazi, Weave Twill, Dutch Weave, nk.

Vipengele

Upinzani wa kutu.

Anti-asidi na alkali

Kupambana na joto la juu.

Utendaji mzuri wa kichujio.

Muda mrefu kutumia maisha

Maombi

Katika hali ya asidi, alkali mazingira sieving na kuchuja.

Sekta ya mafuta ya petroli kama matundu ya matope.

Sekta ya nyuzi za kemikali kama matundu ya skrini.

Sekta ya uchomaji kama matundu ya kusafisha asidi.

Maelezo ya Bidhaa

Ubora Unaoweza Kuamini

Square Wire Mesh imeundwa kwa nyenzo za ubora wa juu, kuhakikisha kwamba inakidhi viwango vya ukali vinavyohitajika na tasnia mbalimbali. Kwa kawaida hutengenezwa kwa chuma cha pua, mabati au metali nyingine zinazodumu, matundu haya yameundwa kustahimili hali mbaya ya mazingira. Ujenzi wake thabiti hutoa upinzani bora kwa kutu, kutu, na kuvaa, na kuifanya kufaa kwa matumizi ya ndani na nje. Nafasi za mraba zinazofanana kwenye wavu huruhusu utendakazi thabiti, kuhakikisha kwamba inaweza kushughulikia mahitaji ya mradi wowote.

Faida Zinazojitokeza

Moja ya faida za msingi za Square Wire Mesh ni matumizi mengi. Inaweza kutumika katika programu nyingi, kutoka kwa uzio na vizuizi vya usalama hadi mifumo ya uchujaji na miundo ya usanifu. Matundu yanapatikana katika ukubwa na vipimo mbalimbali vya waya, hivyo basi kuruhusu ubinafsishaji kukidhi mahitaji mahususi ya mradi. Kubadilika huku kunaifanya kuwa chaguo bora kwa tasnia kama vile kilimo, ujenzi, uchimbaji madini na utengenezaji.

Faida nyingine muhimu ni urahisi wa ufungaji. Meshi ya Waya ya Mraba inaweza kukatwa, kutengenezwa, na kusukumwa kwa urahisi, na kuifanya kuwa chaguo rahisi kwa wakandarasi na wapenda DIY sawa. Asili yake nyepesi inaruhusu utunzaji wa moja kwa moja, kupunguza gharama za kazi na wakati wakati wa ufungaji. Zaidi ya hayo, muundo wazi wa matundu hukuza mtiririko wa hewa na mifereji ya maji, na kuifanya kuwa chaguo bora kwa matumizi ya mandhari na bustani.

Mazingira ya Matumizi

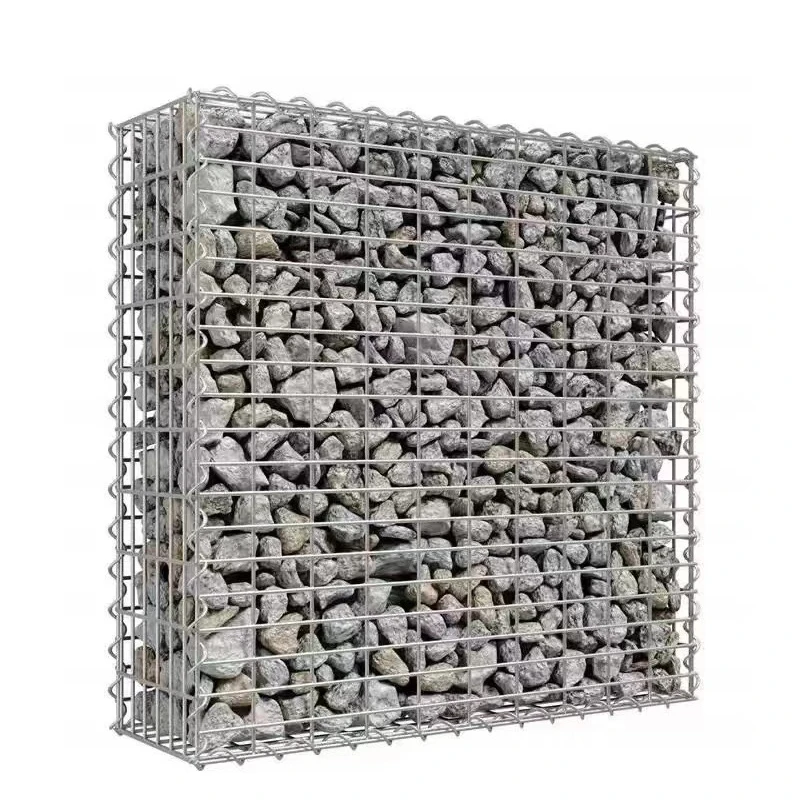

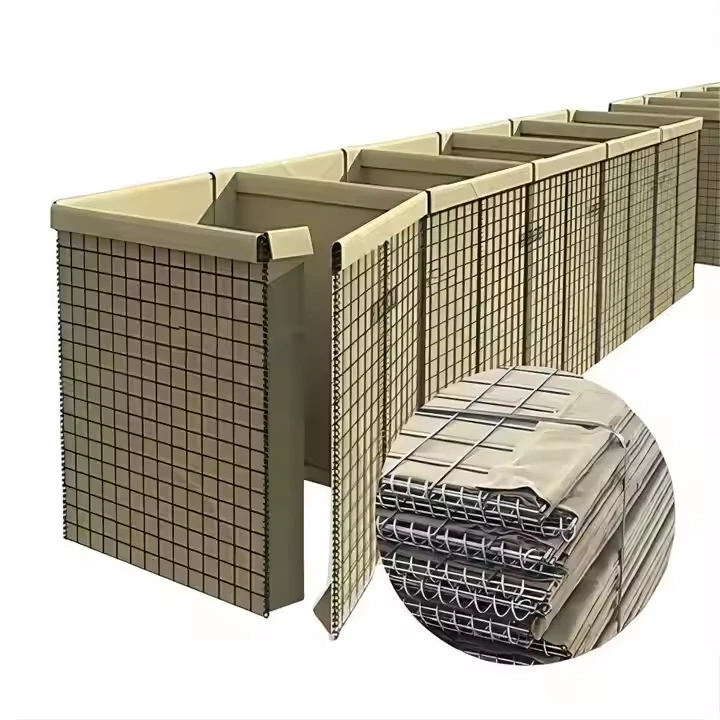

Square Wire Mesh imeundwa kufanya vyema katika mazingira mbalimbali. Katika mazingira ya kilimo, hutumiwa kwa kawaida kwa uzio wa mifugo, kuunda trellis kwa mimea ya kupanda, na kama vikwazo vya ulinzi kwa mazao. Katika ujenzi, hutumika kama uimarishaji wa saruji, kutoa nguvu na utulivu wa miundo. Mesh pia inatumika sana katika matumizi ya viwandani, kama vile utengenezaji wa skrini, vichungi na walinzi wa usalama.

Weave Patterns Explained: Plain, Twill & Dutch Weave in Square Wire Mesh

The performance of square weave mesh hinges on its weave pattern, with plain, twill, and Dutch weaves each engineered to meet distinct industrial demands. JINJIU’s expertise in metal weave mesh ensures each pattern—crafted from materials like stainless steel weave mesh—delivers precision, strength, and versatility across applications.

Plain weave, the most recognizable pattern, features alternating warp and weft wires crossing at 90-degree angles, creating uniform square or rectangular openings (0.5mm to 10mm). This simplicity makes square weave mesh ideal for general-purpose uses: as safety guards for machinery, where visibility and airflow matter, or as fencing for animal enclosures. Constructed from metal weave mesh (carbon steel or stainless steel), plain weave balances cost-effectiveness with durability. For corrosive environments—such as chemical processing plants—stainless steel weave mesh in plain weave resists rust, ensuring long-term reliability.

Twill weave introduces a diagonal texture, formed by warp wires passing over two or more weft wires before alternating. This design enhances tensile strength, making it suitable for high-stress applications. Square weave mesh in twill weave often uses thicker wires (0.8mm to 3mm), making it a top choice for heavy-duty industrial filters or reinforcing panels in construction. Its dense structure blocks debris while maintaining structural integrity, a trait amplified when crafted from stainless steel weave mesh for resistance to high temperatures or pressure.

Dutch weave stands out for its tight, dense pattern: finer weft wires are closely spaced and woven over/under thicker warp wires, creating a smooth surface with minimal openings (as small as 0.02mm). Dutch weave mesh excels in precision filtering—from water treatment (removing micro-particles) to pharmaceutical manufacturing (sifting fine powders). JINJIU’s Dutch weave mesh uses stainless steel weave mesh as standard, ensuring chemical resistance and easy cleaning, critical for sterile environments.

Each pattern in square weave mesh serves a purpose: plain for accessibility, twill for strength, and Dutch for precision. As a leader in metal weave mesh, JINJIU tailors these patterns to industry needs—whether a plain weave fence for agriculture or Dutch weave mesh for high-purity filtration—proving that the right weave transforms a simple mesh into a targeted solution.

From Oil Filtration to Agriculture: Industrial Applications of Square Wire Mesh

Square weave mesh emerges as a versatile workhorse across industries, with its adaptability rooted in diverse configurations—from fine Dutch weave mesh to rugged metal weave mesh. JINJIU’s range, including corrosion-resistant stainless steel weave mesh, ensures tailored solutions for applications as varied as oil filtration and agricultural fencing.

In oil and gas, precision is non-negotiable, making Dutch weave mesh indispensable. Its tightly woven structure (with weft wires finer than warp wires) filters out micro-particles (as small as 0.01mm) from crude oil or hydraulic fluids, preventing equipment damage. Stainless steel weave mesh variants excel here: their resistance to high temperatures (up to 800°C) and chemical corrosion ensures longevity in refineries, where exposure to hydrocarbons and solvents is constant.

Water treatment facilities rely on square weave mesh for purification. Municipal plants use stainless steel weave mesh in sediment filters, capturing debris while withstanding chlorinated water. For industrial wastewater, metal weave mesh with larger openings (5-10mm) acts as a pre-filter, removing sludge before finer treatments—its durability allows for frequent backwashing without tearing.

Agriculture benefits from the mesh’s rugged simplicity. Square weave mesh fencing protects crops from wildlife: 2-5cm openings deter rodents and birds while letting sunlight penetrate. Livestock enclosures use heavier metal weave mesh, with 10-20mm openings containing cattle or sheep without restricting movement. In greenhouse settings, stainless steel weave mesh trellises support climbing plants (cucumbers, beans), resisting humidity and fungal growth better than plastic alternatives.

Construction and mining leverage square weave mesh for reinforcement. Metal weave mesh panels reinforce concrete in tunnels or retaining walls, distributing stress to prevent cracks. Mining operations use it as screens to separate ore sizes, with stainless steel weave mesh variants enduring abrasive materials and harsh chemicals.

Agricultural fencing finds square weave mesh ideal for containing poultry or livestock. It is uniform openings (2-10cm) balance visibility and security, while stainless steel weave mesh resists rust from rain or manure. For erosion control in farmland, it stabilizes soil on slopes, preventing runoff without hindering plant growth.

From deep-sea oil rigs to rural farms, square weave mesh adapts—with JINJIU’s Dutch weave mesh, stainless steel weave mesh, and metal weave mesh ensuring each application gets the precision it demands.