Introduktion af firkantet trådnet

I det stadigt udviklende landskab af byggeri, fremstilling og forskellige industrielle applikationer er efterspørgslen efter pålidelige og alsidige materialer altafgørende. Blandt disse materialer skiller Square Wire Mesh sig ud som et foretrukket valg på tværs af adskillige sektorer. Med sine unikke egenskaber og vidtfavnende anvendelser har Square Wire Mesh vundet popularitet i lande over hele kloden, takket være dets enestående kvalitet, avancerede teknologi og adskillige fordele.

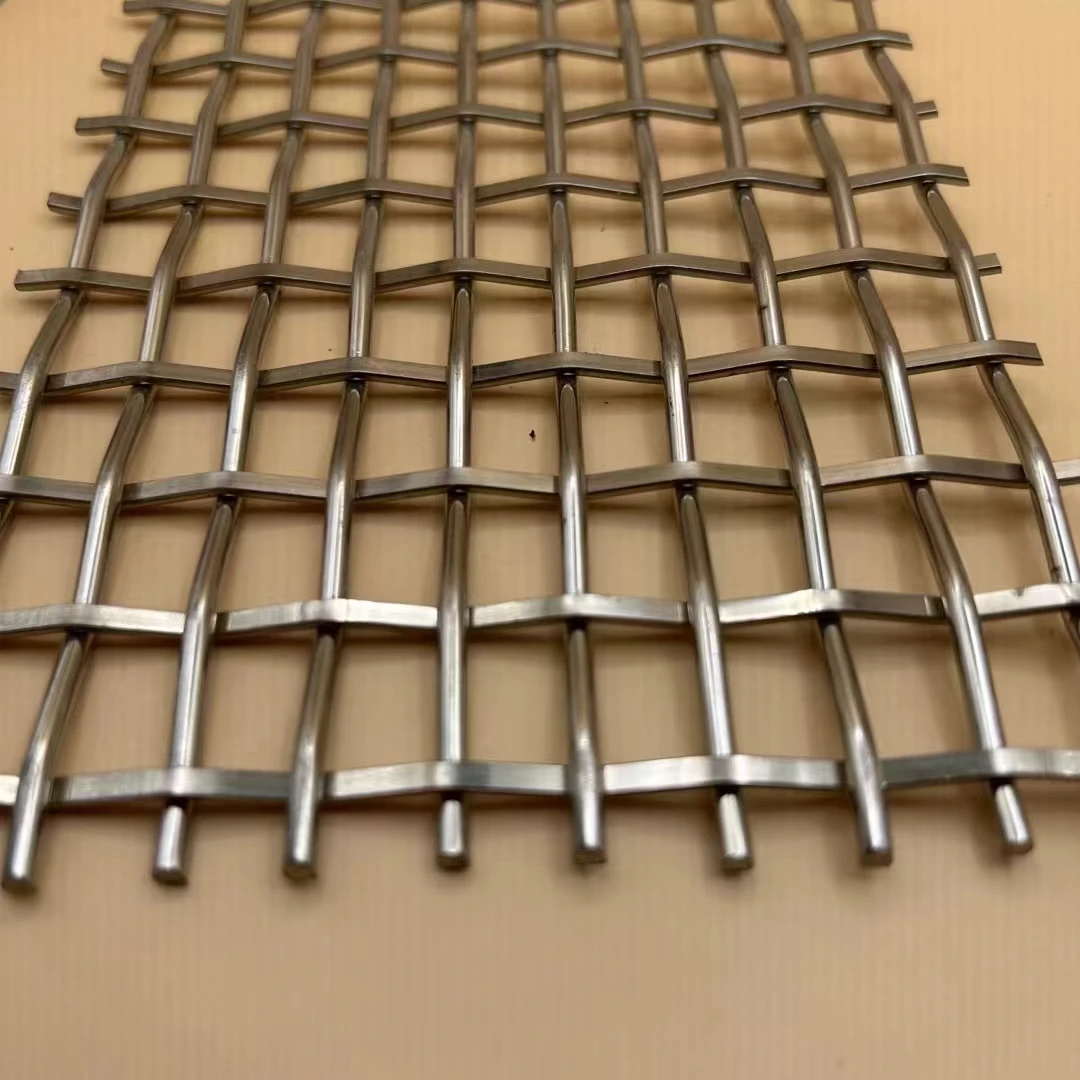

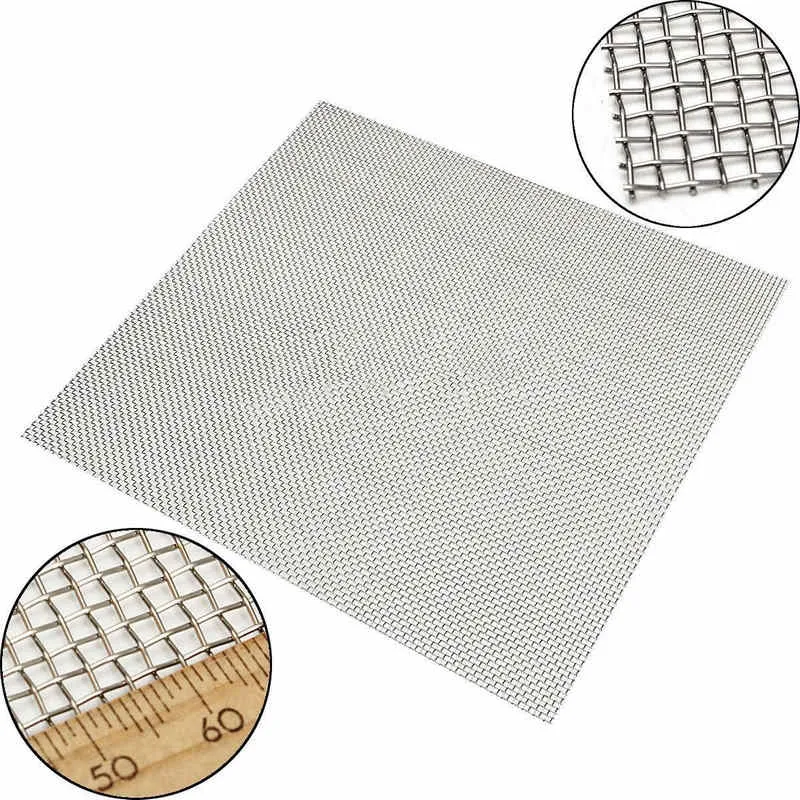

Square Wire Mesh er en type vævet trådnet kendetegnet ved sine firkantede åbninger. Det er typisk lavet af højkvalitets stål, rustfrit stål eller andre holdbare materialer, hvilket sikrer styrke og lang levetid. Nettet er produceret gennem en væveproces, der skaber et gitterlignende mønster, hvilket gør det velegnet til forskellige applikationer, fra byggeri til landbrug.

Produktbeskrivelse

1.Material: AISI302, 304,316,316L,310S,410,430,904L,2205,2507,etc

2.Wire Diameter: 0.015-2.8mm

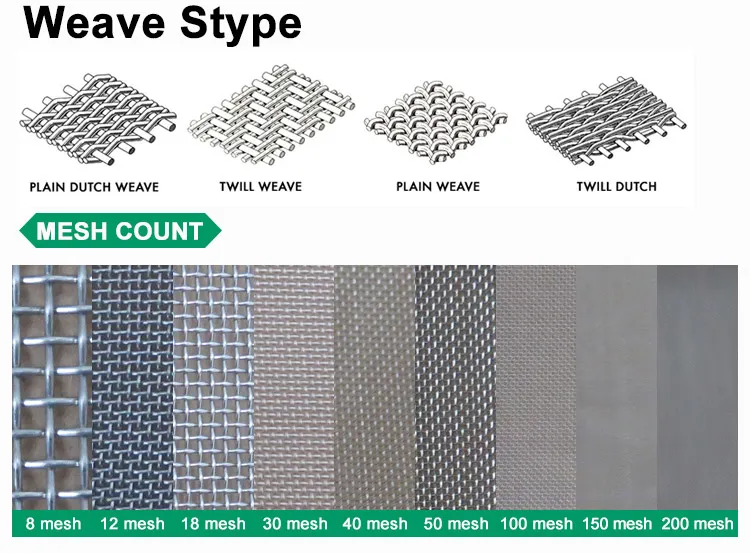

3. Maskeantal:

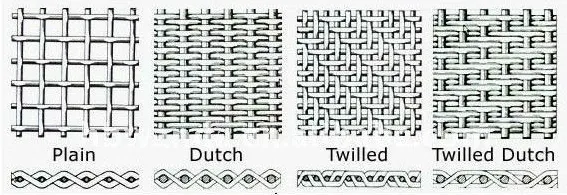

Plain weave can be woven up to 400 mesh.

Twill weave can be woven from 400 to 635mesh.

Dutch weave can be woven up to 3500mesh

- Væve mønster:

Plain vævning, twill vævning, hollandsk vævning osv.

Funktioner

Korrosionsbestandighed.

Anti-syre og alkali

Anti-høj temperatur.

God filterydelse.

Lang levetid

Anvendelse

I sure, alkaliske miljøforhold sigtning og filtrering.

Petroleumsindustrien som muddernet,.

Kemisk fiberindustri som skærmnet.

Pletteringsindustrien som syrerensningsnet.

Produktdetaljer

Kvalitet du kan stole på

Square Wire Mesh er fremstillet af materialer af høj kvalitet, hvilket sikrer, at det opfylder de strenge standarder, der kræves af forskellige industrier. Dette net er typisk lavet af rustfrit stål, galvaniseret stål eller andre holdbare metaller, og det er konstrueret til at modstå barske miljøforhold. Dens robuste konstruktion giver fremragende modstandsdygtighed over for korrosion, rust og slid, hvilket gør den velegnet til både indendørs og udendørs applikationer. De ensartede firkantede åbninger i nettet muliggør ensartet ydeevne, hvilket sikrer, at det kan klare kravene til ethvert projekt.

Fordele, der skiller sig ud

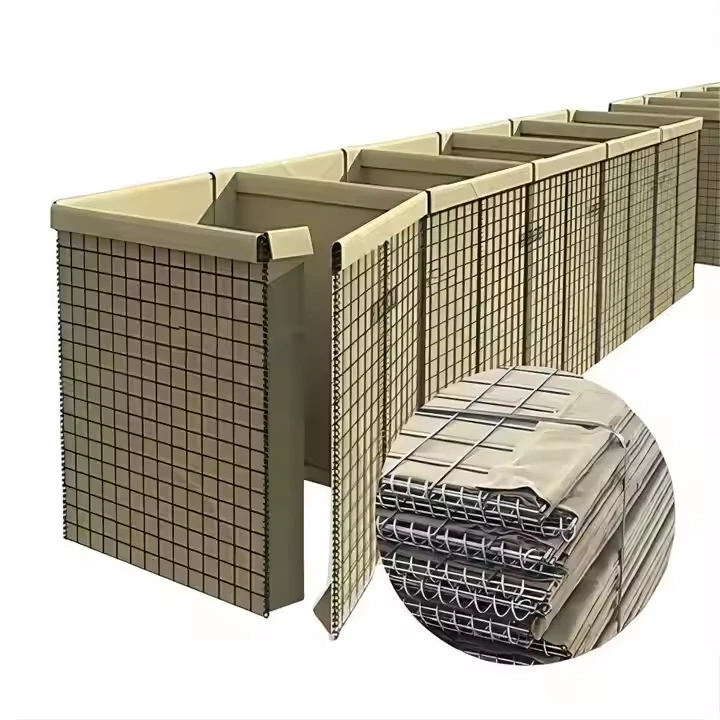

En af de primære fordele ved Square Wire Mesh er dens alsidighed. Det kan bruges i et væld af applikationer, fra hegn og sikkerhedsbarrierer til filtreringssystemer og arkitektoniske designs. Nettet fås i forskellige størrelser og trådmålere, hvilket giver mulighed for tilpasning til at opfylde specifikke projektkrav. Denne tilpasningsevne gør den til et ideelt valg til industrier som landbrug, byggeri, minedrift og fremstilling.

En anden væsentlig fordel er dens lette installation. Square Wire Mesh kan nemt skæres, formes og svejses, hvilket gør det til en praktisk mulighed for både entreprenører og gør-det-selv-entusiaster. Dens lette natur giver mulighed for ligetil håndtering, hvilket reducerer arbejdsomkostninger og tid under installationen. Derudover fremmer nettets åbne design luftstrøm og dræning, hvilket gør det til et fremragende valg til landskabs- og havebrug.

Brugsmiljø

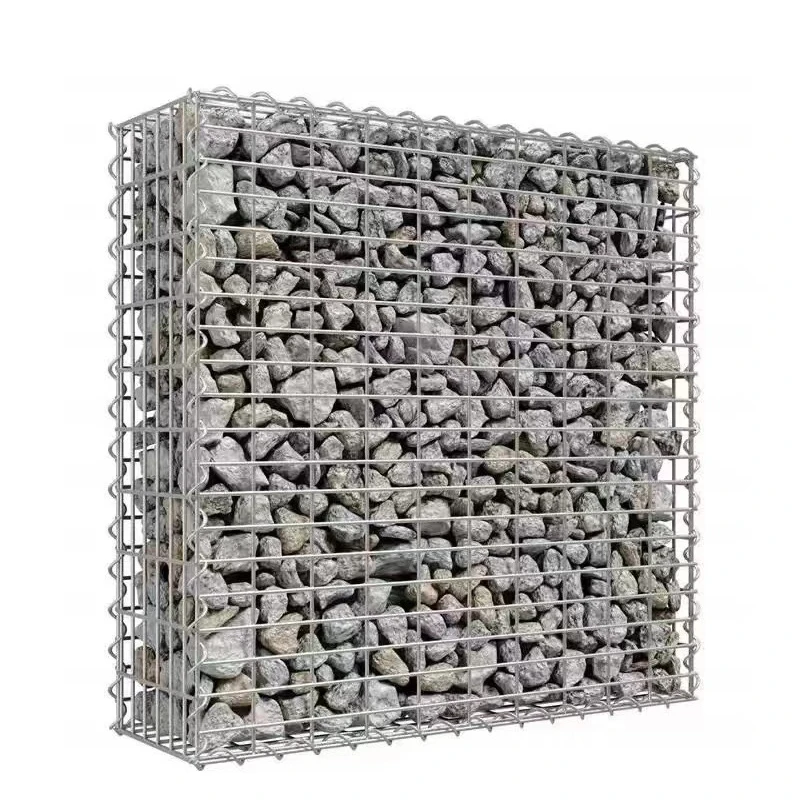

Square Wire Mesh er designet til at fungere usædvanligt godt i forskellige miljøer. I landbrugsmiljøer bruges det almindeligvis til at indhegne husdyr, skabe espalier til klatreplanter og som beskyttende barrierer for afgrøder. I byggeriet tjener det som forstærkning af beton, hvilket giver øget styrke og stabilitet til strukturer. Nettet er også meget brugt i industrielle applikationer, såsom til fremstilling af skærme, filtre og sikkerhedsafskærmninger.

Weave Patterns Explained: Plain, Twill & Dutch Weave in Square Wire Mesh

The performance of square weave mesh hinges on its weave pattern, with plain, twill, and Dutch weaves each engineered to meet distinct industrial demands. JINJIU’s expertise in metal weave mesh ensures each pattern—crafted from materials like stainless steel weave mesh—delivers precision, strength, and versatility across applications.

Plain weave, the most recognizable pattern, features alternating warp and weft wires crossing at 90-degree angles, creating uniform square or rectangular openings (0.5mm to 10mm). This simplicity makes square weave mesh ideal for general-purpose uses: as safety guards for machinery, where visibility and airflow matter, or as fencing for animal enclosures. Constructed from metal weave mesh (carbon steel or stainless steel), plain weave balances cost-effectiveness with durability. For corrosive environments—such as chemical processing plants—stainless steel weave mesh in plain weave resists rust, ensuring long-term reliability.

Twill weave introduces a diagonal texture, formed by warp wires passing over two or more weft wires before alternating. This design enhances tensile strength, making it suitable for high-stress applications. Square weave mesh in twill weave often uses thicker wires (0.8mm to 3mm), making it a top choice for heavy-duty industrial filters or reinforcing panels in construction. Its dense structure blocks debris while maintaining structural integrity, a trait amplified when crafted from stainless steel weave mesh for resistance to high temperatures or pressure.

Dutch weave stands out for its tight, dense pattern: finer weft wires are closely spaced and woven over/under thicker warp wires, creating a smooth surface with minimal openings (as small as 0.02mm). Dutch weave mesh excels in precision filtering—from water treatment (removing micro-particles) to pharmaceutical manufacturing (sifting fine powders). JINJIU’s Dutch weave mesh uses stainless steel weave mesh as standard, ensuring chemical resistance and easy cleaning, critical for sterile environments.

Each pattern in square weave mesh serves a purpose: plain for accessibility, twill for strength, and Dutch for precision. As a leader in metal weave mesh, JINJIU tailors these patterns to industry needs—whether a plain weave fence for agriculture or Dutch weave mesh for high-purity filtration—proving that the right weave transforms a simple mesh into a targeted solution.

From Oil Filtration to Agriculture: Industrial Applications of Square Wire Mesh

Square weave mesh emerges as a versatile workhorse across industries, with its adaptability rooted in diverse configurations—from fine Dutch weave mesh to rugged metal weave mesh. JINJIU’s range, including corrosion-resistant stainless steel weave mesh, ensures tailored solutions for applications as varied as oil filtration and agricultural fencing.

In oil and gas, precision is non-negotiable, making Dutch weave mesh indispensable. Its tightly woven structure (with weft wires finer than warp wires) filters out micro-particles (as small as 0.01mm) from crude oil or hydraulic fluids, preventing equipment damage. Stainless steel weave mesh variants excel here: their resistance to high temperatures (up to 800°C) and chemical corrosion ensures longevity in refineries, where exposure to hydrocarbons and solvents is constant.

Water treatment facilities rely on square weave mesh for purification. Municipal plants use stainless steel weave mesh in sediment filters, capturing debris while withstanding chlorinated water. For industrial wastewater, metal weave mesh with larger openings (5-10mm) acts as a pre-filter, removing sludge before finer treatments—its durability allows for frequent backwashing without tearing.

Agriculture benefits from the mesh’s rugged simplicity. Square weave mesh fencing protects crops from wildlife: 2-5cm openings deter rodents and birds while letting sunlight penetrate. Livestock enclosures use heavier metal weave mesh, with 10-20mm openings containing cattle or sheep without restricting movement. In greenhouse settings, stainless steel weave mesh trellises support climbing plants (cucumbers, beans), resisting humidity and fungal growth better than plastic alternatives.

Construction and mining leverage square weave mesh for reinforcement. Metal weave mesh panels reinforce concrete in tunnels or retaining walls, distributing stress to prevent cracks. Mining operations use it as screens to separate ore sizes, with stainless steel weave mesh variants enduring abrasive materials and harsh chemicals.

Agricultural fencing finds square weave mesh ideal for containing poultry or livestock. It is uniform openings (2-10cm) balance visibility and security, while stainless steel weave mesh resists rust from rain or manure. For erosion control in farmland, it stabilizes soil on slopes, preventing runoff without hindering plant growth.

From deep-sea oil rigs to rural farms, square weave mesh adapts—with JINJIU’s Dutch weave mesh, stainless steel weave mesh, and metal weave mesh ensuring each application gets the precision it demands.