Hesco Barriere

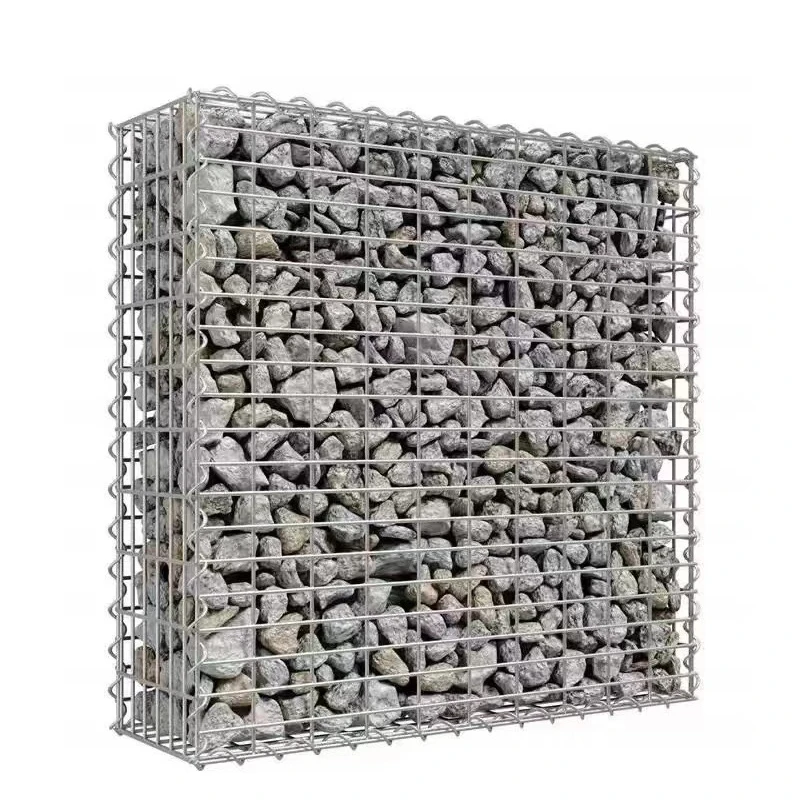

Det eksplosionssikre bur, også kendt som eksplosionssikker væg eller eksplosionssikkert net, også kendt som Hesco barriere eller Hesco fæstning, er en vigtig form for beskyttelse i moderne krigsførelse og oversvømmelseskontrol. Ved faktisk brug danner den en solid beskyttelsesvæg af trådnet ved at fylde sten, sand eller jord i netburet. På grund af dens anbefalede installation, sammenfoldelige og nemme betjening anvendes den i moderne krigsførelse.

|

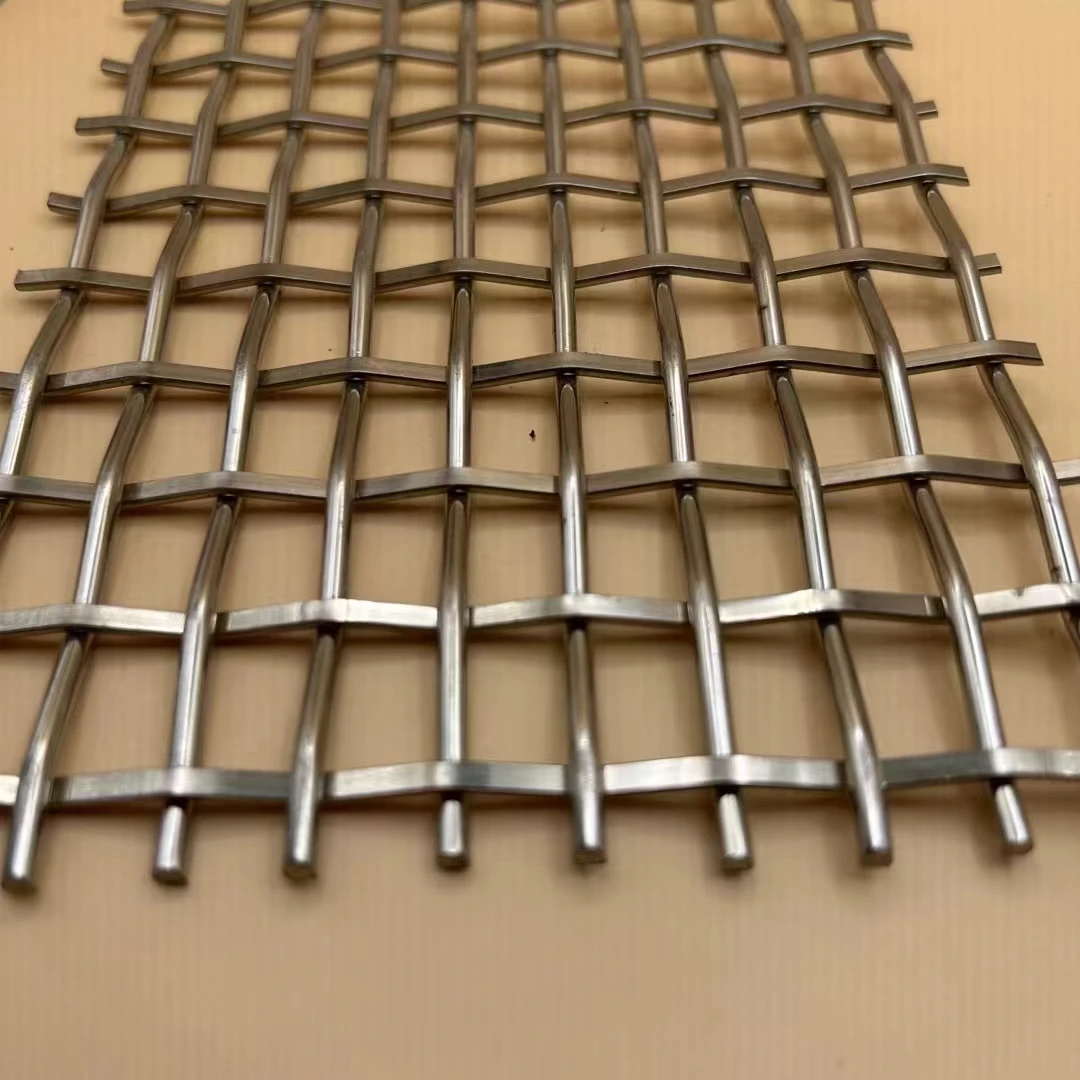

Mesh tråd diameter

|

3 mm, 4 mm, 5 mm, 6 mm osv

|

|

Fjedertråds diameter

|

3 mm, 4 mm, 5 mm, 6 mm osv

|

|

Maskestørrelse

|

50*50mm,50*100mm,37,5*100mm,60*60mm,65*65mm,70*70mm,76*76mm,80*80mm eller

som din anmodning.

|

|

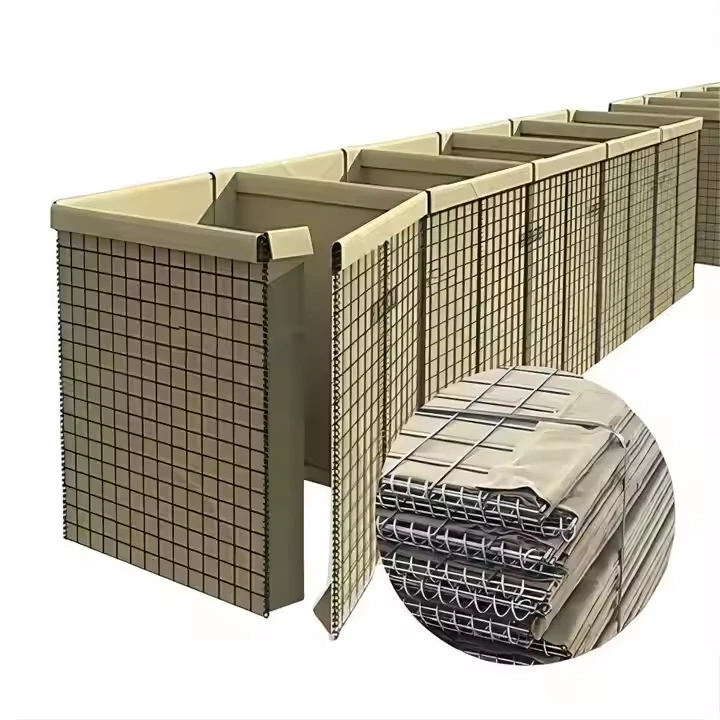

Panelstørrelse

|

0,61*0,61m,1*1m,1,2*1,2m,1,5*1,5m,1,5*2m,2*2m, 2,21*2,13m eller som din anmodning.

|

|

Slutte

|

Elektrogalvaniseret efter svejsning

Varmgalvaniseret svejset

Galfan belagt efter svejsning

|

|

Geotekstil

|

Kraftig ikke-vævet polypropylen

|

|

Pakning

|

Indpakket med krympefilm eller pakket i palle

|

En defensiv barriere / defensiv barriere er en moderne type gabion, der bruges til forsvar og oversvømmelsessikring. Den er lavet af en sammenklappelig trådnetbeholder og et kraftigt stoffor og kan bruges som en enkelt enhed eller flere enheder forbundet med hinanden

Emballage detalje

Indpakket med krympefilm eller pakket i palle.5-10 enheder på pallen.

Anvendelse

1) Perimetersikkerhed og forsvarsmure

2) Beskyttelse af eksisterende strukturer

3) Søgeområder for sprængstoffer og smuglergods

4) Beskyttelsesteknik af kystområde

5) Defensive skydestillinger

6) Oversvømmelseskontrol støttemur

Vi introducerer vores førsteklasses Hesco-barrierer, ekspertdesignet til at give overlegen beskyttelse og befæstelse til forskellige applikationer, fra militær brug til byggepladser og nødberedskabsscenarier. Vores barrierer er konstrueret af højkvalitets, holdbare materialer, der sikrer langvarig ydeevne og pålidelighed selv i de mest krævende miljøer. Hver Hesco barriere har en robust svejset trådnetstruktur, fyldt med ikke-vævet geotekstilstof, som giver mulighed for enestående styrke og stabilitet.

Det unikke design af vores barrierer giver nem implementering, hvilket muliggør hurtig opsætning i kritiske situationer, hvor tiden er afgørende. Alsidigheden af vores Hesco-barrierer gør dem ideelle til oversvømmelseskontrol, indeslutning af farlige materialer og giver en sikker perimeter omkring følsomme områder. De kan også prale af evnen til at modstå ugunstige vejrforhold, hvilket sikrer, at dine befæstninger forbliver intakte gennem storme, oversvømmelser eller kraftig vind. Hver barriere er konstrueret til at absorbere påvirkningen effektivt, hvilket gør dem til et pålideligt valg for både militære operationer og civilingeniørprojekter.

Med fokus på sikkerhed er vores Hesco-barrierer designet til at opfylde strenge industristandarder, hvilket giver ro i sindet til brugerne ved at sikre maksimal beskyttelse. Innovativt designet til modularitet og tilpasningsevne, kan vores barrierer nemt kobles sammen for at skabe større konfigurationer efter behov, hvilket gør dem til et vigtigt værktøj for ethvert byggeri eller beredskabsteam. Invester i kvaliteten og holdbarheden af vores Hesco-barrierer for uovertruffen beskyttelse og ro i sindet. Uanset om du beskytter en byggeplads, forbereder dig på naturkatastrofer eller etablerer sikre militærlejre, så stol på, at vores Hesco-barrierer leverer den pålidelige ydeevne, du har brug for. Vælg vores brancheførende Hesco-barrierer i dag, og befæst dit forsvar med tillid.

Defensive Barrier Specifications: Mesh Sizes, Panel Dimensions & Coatings

At the core of effective defensive barriers lies precision in design—and Hesco barriers excel here, with specifications engineered for reliability in military, flood control, and industrial security. As a leading provider, JINJIU ensures every detail of these defence barrier systems—from mesh weave to coating thickness—aligns with high-stakes operational demands.

Mesh sizes are critical for structural integrity. Hesco barriers feature double-twisted hexagonal mesh, with standard openings ranging from 2.5×5cm to 5×10cm. The 2.5×5cm mesh, ideal for military defence barrier setups, prevents fine aggregate (like sand or gravel) from escaping when filled, ensuring the barrier retains shape under impact. For flood control or perimeter security, 5×10cm mesh balances strength with drainage, allowing water to pass while trapping larger fill materials (rock, concrete blocks) to reinforce the structure. All meshes use high-tensile steel wire (2.5-4.0mm diameter), resistant to cutting or deformation.

Panel dimensions cater to rapid deployment and scalability. Standard panels come in lengths of 1m, 3m, and 6m, with heights ranging from 0.5m to 3m—flexible enough for everything from temporary roadblocks to permanent border fortifications. The 3m×1m panel is a workhorse: lightweight (15-20kg) for quick manual installation, yet robust enough to form a 1m-high defensive barrier when filled. For larger projects, 6m×2m panels reduce assembly time, as fewer units cover more ground, while 0.5m-high variants suit low-profile security zones like industrial yards.

Coatings enhance durability across environments. Galvanized coatings (80-120g/m² zinc) are standard, protecting against rust in humid or coastal areas—vital for defensive barriers deployed long-term. For extreme conditions (chemical exposure, saltwater), PVC coatings (0.2-0.5mm thick) add a secondary layer, extending service life to 15+ years. These coatings adhere seamlessly to the mesh, ensuring no weak points where corrosion could start.

JINJIU’s Hesco barriers marry these specifications to purpose: tight 2.5×5cm mesh for military defence barrier resilience, 6m panels for rapid flood response, and dual coatings for all-weather reliability. Each component works in tandem, proving that in defensive barriers, precision isn’t just a detail—it’s the foundation of security.

The Science of Strength: What Makes Defensive Barriers Withstand Impact

Behind every defensive barrier that repels collisions, blasts, or forced entry lies a deliberate blend of material science and structural engineering. JINJIU’s defence barrier systems are engineered to turn impact energy into manageable force, ensuring they stand firm in military operations, riot control, and critical infrastructure protection.

Material selection is the first line of defense. High-tensile steel—with a minimum yield strength of 350MPa—forms the core of these defensive barriers. This steel undergoes cold working, aligning its molecular structure to resist deformation; even under 10,000N of force (equivalent to a 2-ton vehicle impact at 10km/h), the metal bends minimally before returning to shape. For coastal or corrosive environments, galvanized coatings (120g/m² zinc) add a protective layer, ensuring strength isn’t compromised by rust over time.

Structural design amplifies impact resistance. Modular panels with interlocking joints distribute force evenly across the defence barrier system, preventing localized failure. For example, 3m-wide panels connect via steel pins that absorb 30% of impact energy through controlled flexing, while reinforced edges (6mm steel plating) resist puncturing. When filled with aggregate (rock, concrete), the barrier’s mass acts as a kinetic buffer—slowing intruders or debris by converting motion into friction between fill materials.

Testing validates real-world performance. JINJIU’s defensive barriers undergo rigorous trials: 50km/h vehicle impact tests (mimicking ramming attempts), blast simulation (up to 5kg TNT equivalent), and cyclic load testing (10,000+ repetitions of 5kN force). These tests ensure the barrier retains 90% structural integrity post-impact, a critical metric for military defence barrier applications where failure isn’t an option.

Whether stopping a speeding vehicle at a checkpoint or shielding a facility from debris during a storm, the science is clear: strength comes from intentional design. JINJIU’s defensive barriers don’t just resist impact—they outsmart it, turning force into a testament to engineering excellence.