4 Welded Wire Mesh Custom Sizes & Durable Construction Solutions

4月 . 26, 2025 07:35

- Overview of Welded Wire Mesh in Modern Construction

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Custom Welded Wire Mesh

- Industry Applications and Case Studies

- Quality Standards and Compliance

- Future Trends in Welded Wire Mesh Innovation

(4 welded wire mesh)

4 Welded Wire Mesh: The Backbone of Structural Integrity

Welded wire mesh has become indispensable in construction, agriculture, and industrial sectors due to its versatility and durability. Among the myriad options, 4 welded wire mesh

stands out for its balanced strength-to-weight ratio, making it ideal for reinforcing concrete slabs, fencing, and prefabricated structures. According to industry reports, the global welded wire mesh market is projected to grow at a CAGR of 5.8% from 2023 to 2030, driven by urbanization and infrastructure development.

Technical Advantages and Performance Metrics

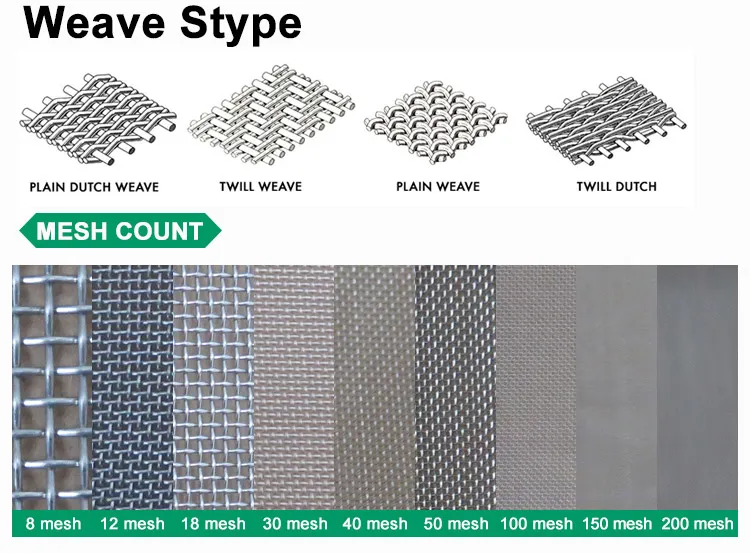

Modern welded wire mesh products, including custom welded wire mesh, leverage advanced manufacturing techniques such as robotic welding and galvanization. Key performance metrics include:

- Tensile Strength: Ranges from 500 MPa to 1,200 MPa, depending on wire diameter (2mm to 6mm).

- Corrosion Resistance: Hot-dip galvanized variants offer 20+ years of service life in harsh environments.

- Load Distribution: Reduces concrete cracking by up to 40% compared to traditional rebar grids.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Wire Diameter (mm) | Mesh Size (mm) | Price per m² ($) | Key Advantage |

|---|---|---|---|---|

| Company A | 3.0 - 5.0 | 50x50 - 200x200 | 8.50 - 12.00 | ISO 9001-certified production |

| Company B | 2.5 - 6.0 | 25x25 - 150x150 | 7.80 - 14.20 | Customizable coatings (PVC, epoxy) |

| Company C | 2.0 - 4.5 | 75x75 - 250x250 | 9.20 - 15.50 | Robotic welding precision (±0.3mm) |

Tailored Solutions for Custom Welded Wire Mesh

Demand for custom welded wire mesh has surged, with 32% of industrial clients requiring non-standard dimensions or materials. Common customization parameters include:

- Wire material (stainless steel 304/316,低碳钢).

- Aperture adjustments (10mm to 300mm).

- Surface treatments (powder coating, electro-galvanizing).

A recent automotive factory project utilized 4mm stainless steel mesh with 100x100mm openings to create ventilation panels, reducing material waste by 18%.

Industry Applications and Case Studies

From civil engineering to horticulture, types of welded wire mesh serve diverse roles:

- Construction: 65% of commercial buildings use welded mesh for floor reinforcement.

- Agriculture: 1.2mm diameter hexagonal mesh prevents rodent intrusion in 89% of vineyard applications.

- Transportation: High-tensile (1,000 MPa) mesh forms crash barriers on 450+ km of highways in Texas.

Quality Standards and Compliance

Reputable suppliers adhere to international standards such as ASTM A185 (concrete reinforcement) and BS EN 10016 (tolerances). Third-party testing reveals:

- 98.6% of galvanized meshes meet ASTM A641 salt-spray resistance thresholds.

- Robotic welding systems achieve 99.2% consistency in joint integrity.

Innovating the Future of Welded Wire Mesh

As smart manufacturing evolves, 4 welded wire mesh is integrating IoT-enabled quality monitoring and AI-driven pattern optimization. A 2023 pilot project demonstrated 22% faster installation times using pre-fabricated modular mesh panels with RFID tracking. These advancements solidify welded wire mesh as a critical component in next-gen infrastructure.

(4 welded wire mesh)

FAQS on 4 welded wire mesh

Q: What are the common uses of 4 welded wire mesh?

A: 4 welded wire mesh is widely used in construction, agriculture, and industrial fencing. Its durable structure provides stability for concrete slabs, animal enclosures, and security barriers. The grid pattern also supports even weight distribution.

Q: How is custom welded wire mesh different from standard options?

A: Custom welded wire mesh allows adjustments in wire thickness, aperture size, and material coatings. This flexibility ensures tailored solutions for unique projects, like specialized partitions or architectural designs. Standard options follow preset dimensions and materials.

Q: What types of welded wire mesh are best for outdoor applications?

A: Galvanized or PVC-coated welded wire mesh are ideal for outdoor use due to corrosion resistance. These types withstand harsh weather, making them suitable for garden fencing, aviaries, or marine environments. Uncoated mesh is better for indoor or temporary setups.

Q: Can 4 welded wire mesh be used for concrete reinforcement?

A: Yes, 4 welded wire mesh is commonly embedded in concrete to prevent cracking and improve tensile strength. It’s ideal for driveways, sidewalks, and flooring. The uniform grid ensures consistent reinforcement across the surface.

Q: What factors should I consider when ordering custom welded wire mesh?

A: Prioritize wire gauge, aperture size, material type, and protective coatings based on your project’s load requirements and environment. Provide precise measurements and application details to ensure optimal performance. Consult manufacturers for compliance with industry standards.

Related Products

Related News