制作概要

65MN カール金網は、高い引張強度、優れた耐振性、長い耐用年数を備え、最良の価格で正確なスクリーニング結果とサービスを得ることができるため、岩石破砕スクリーンや採掘スクリーンに最適です。

|

65MN材料化学組成

|

|

材料

|

C

|

そして

|

ミネソタ

|

Cr

|

で

|

と

|

|

65Mn鋼

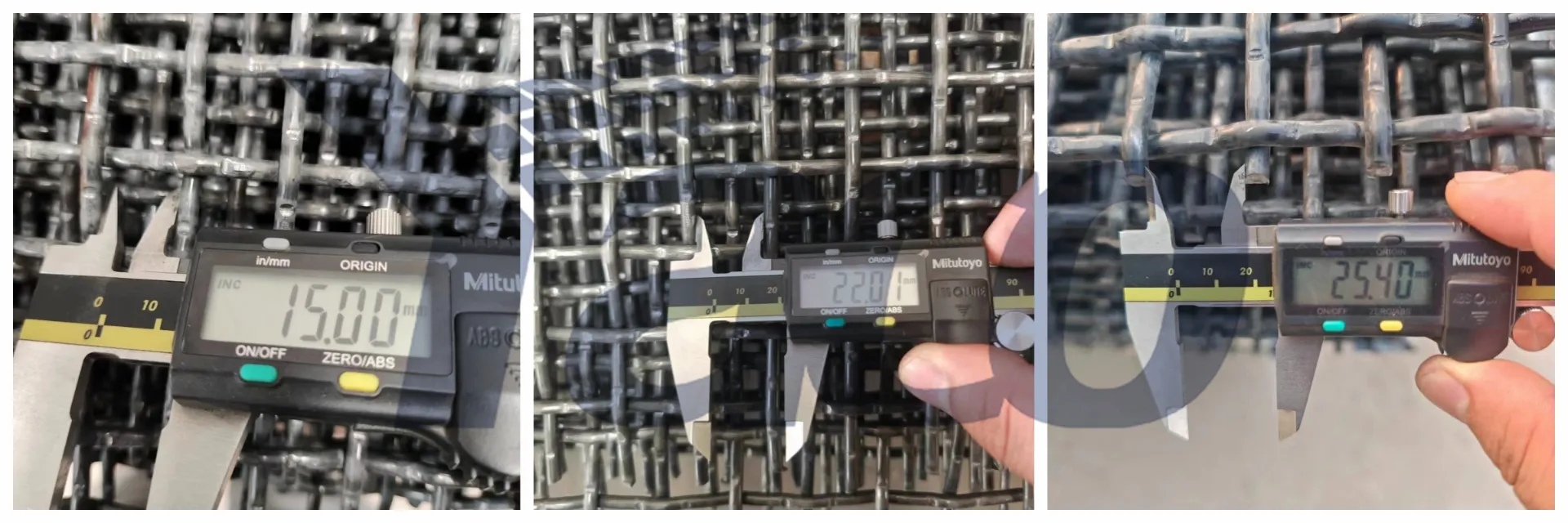

例: 6.5mm

|

0.62-0.70

|

0.17-0.37

|

0.90-1.20

|

≤0.25

|

≤0.30

|

≤0.25

|

|

0.66

|

0.25

|

0.98

|

0.04

|

0.01

|

0.03

|

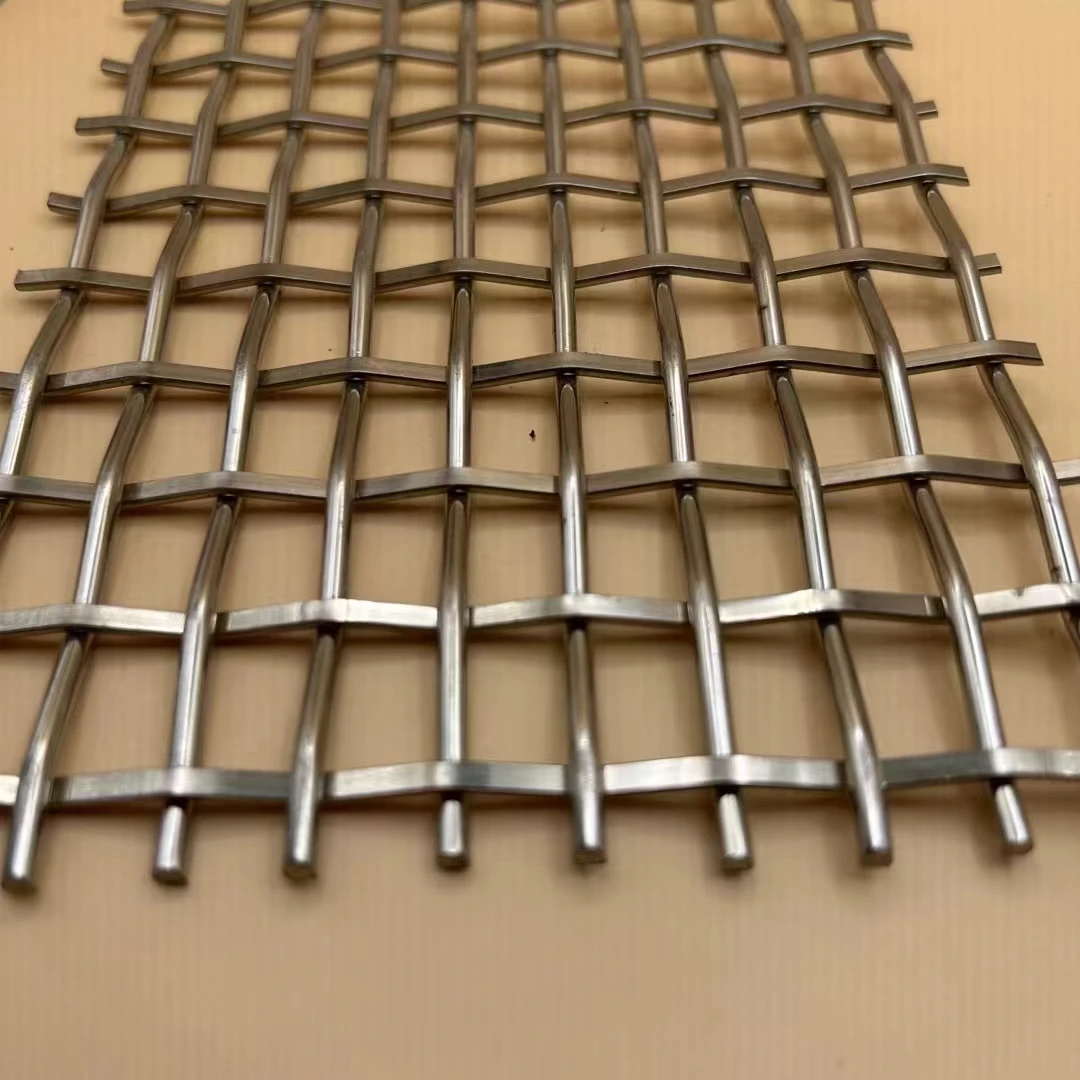

さまざまなエッジ タイプ 頑丈なクリンプ メッシュ素材は、高強度スチール ワイヤ、45# スチール ワイヤ、65Mn スチール ワイヤです。通常、鉱山や石炭産業で石や砂をふるい分けるために使用されます。メッシュ プレートにはさまざまなエッジがあります。

仕様

ご要望に応じて穴のサイズをカスタマイズできます

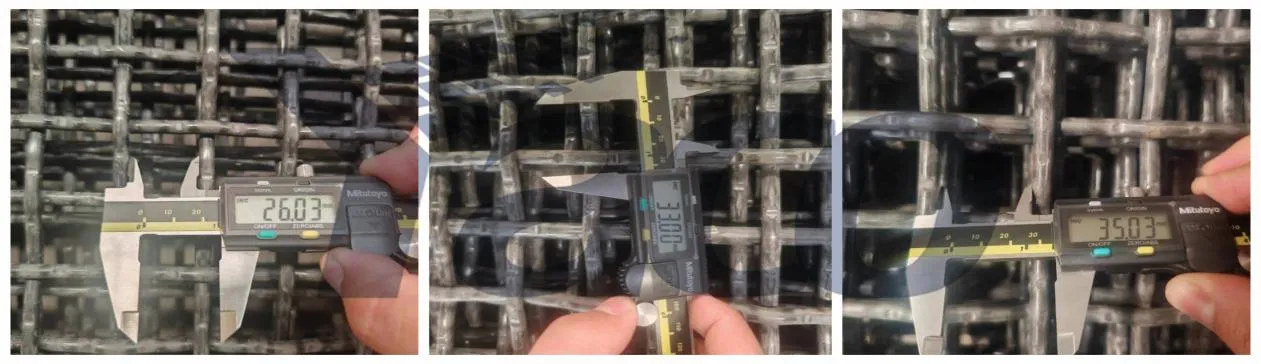

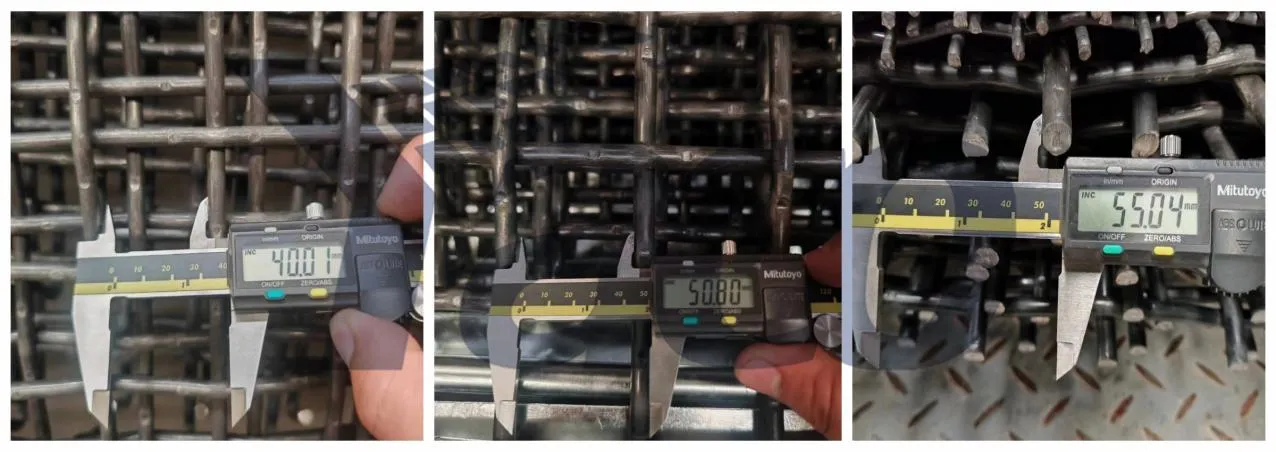

振動する圧着金網スクリーンの異なる穴のサイズの表示:

振動スクリーンメッシュの詳細

|

材料

|

高張力マンガン鋼。

|

|

線径

|

1.5mm - 13mm

|

|

絞り

|

2mm~110mm。

|

|

表面仕上げ

|

ミル仕上げ、防錆油塗布、PVCコーティング

|

|

織り方

|

ダブル圧着、中間圧着、フラットトップ圧着、ロック圧着

|

|

サイズ

|

シートまたはロールで、幅は最大6メートル、長さは最大100メートルです。

|

弊社では、様々なタイプの織り金網をご提供できます: クリンプ金網ロール、織り金網シート、フック付きまたはフックなしの振動スクリーン

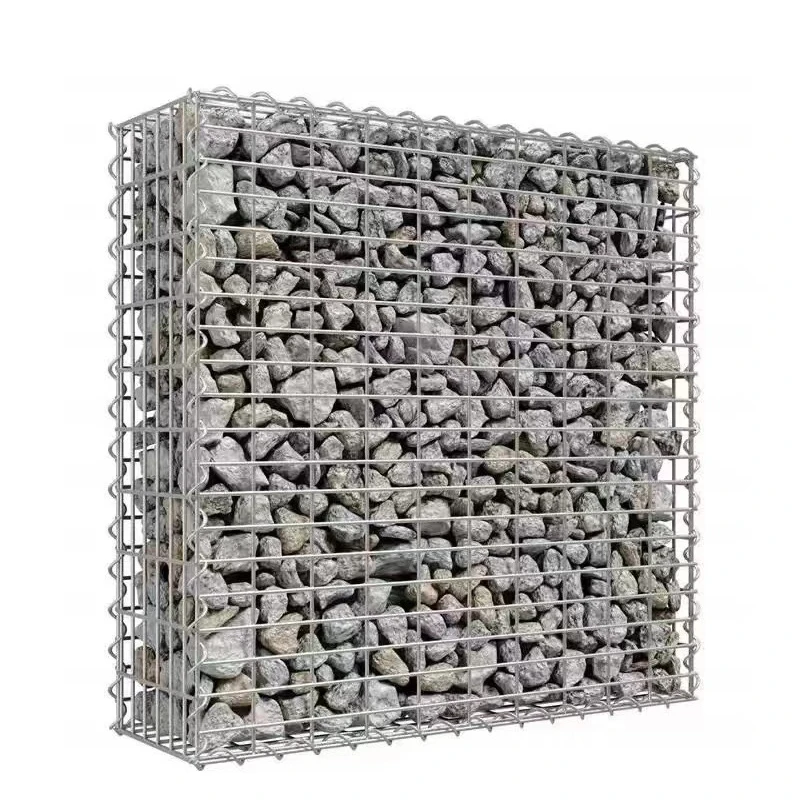

応用

マンガン鋼振動スクリーンは、鉱業、採石業、骨材産業で、さまざまなサイズの砂、砂利、石炭、石、岩、金属材料、その他の鉱石材料をふるい分けるために広く使用されています。

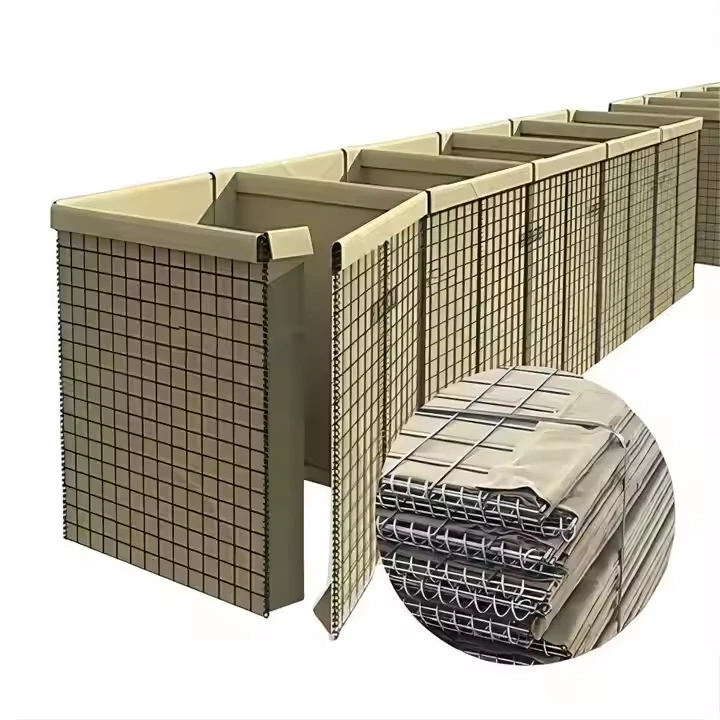

当社のクリンプ ワイヤ メッシュは、さまざまなワイヤ径とメッシュ サイズで提供されており、お客様の特定のニーズに最適なものをお選びいただけます。ろ過目的の細かいメッシュが必要な場合でも、セキュリティ フェンス用の厚いメッシュが必要な場合でも、当社には適切なソリューションがあります。当社のクリンプ ワイヤ メッシュは汎用性が高く、動物の囲い、建築物、防護壁など、さまざまな用途に適しています。

当社のクリンプ ワイヤー メッシュは、強度と汎用性に加え、設置とメンテナンスが簡単な設計になっています。メッシュは簡単にサイズに合わせてカットでき、さまざまなフレーム システムと互換性があるため、セットアップが簡単です。さらに、耐腐食性があるため、過酷な環境でも長持ちします。

Crimped Weave Types: Double, Lock & Intermediate Crimp Differences

Crimped woven wire mesh owes its versatility to specialized weave patterns, with double, lock, and intermediate crimps catering to distinct industrial demands. As a leading crimped wire mesh manufacturer, JINJIU engineers each style to balance strength, flexibility, and durability—whether using carbon steel or stainless steel crimped wire mesh.

Double crimp, the most common variant, features uniform crimps pressed into both warp and weft wires at every intersection. This symmetrical design creates consistent square or rectangular apertures (5mm to 50mm), making crimped wire mesh ideal for general-purpose applications. Mining screens rely on their 3-6mm wire diameter to sift aggregates, while agricultural fencing uses it to contain livestock—its balanced structure resisting deformation under pressure. Stainless steel crimped wire mesh in double crimp excels in food processing, where corrosion resistance and easy cleaning are critical.

Lock crimp (or “interlock crimp”) elevates stability: wires are crimped to interlock at crossings, eliminating slippage even under heavy loads. This design suits high-stress environments, such as construction site safety barriers or heavy machinery guards. With apertures as small as 2mm, crimped woven wire mesh in lock crimp prevents debris penetration, while its rigid structure (using 4-8mm wires) withstands impact. Crimped wire mesh manufacturer JINJIU often recommends this type for industrial filtration, where consistent opening sizes are non-negotiable.

Intermediate crimp strikes a middle ground: warp wires have crimps at every intersection, while weft wires feature crimps at alternating points. This hybrid design offers flexibility without sacrificing strength, making it perfect for curved surfaces—like silo linings or cylindrical screens. Apertures range from 3mm to 30mm, with stainless steel crimped wire mesh variants thriving in chemical processing, where resistance to acids and temperature fluctuations is key. Its adaptability also shines in architectural applications, such as decorative facades, where form meets function.

Each weave type reflects crimped wire mesh’s engineered precision. As a trusted crimped wire mesh manufacturer, JINJIU tailors these patterns: double crimp for reliability, lock crimp for extreme strength, and intermediate crimp for versatility. Whether for mining, construction, or food safety, crimped woven wire mesh delivers—proving that the right crimp transforms performance.

Crimped vs. Ordinary Wire Mesh: Why It Excels in Building Applications

In building applications, the choice between crimped wire mesh and ordinary wire mesh hinges on performance under stress—and crimped woven wire mesh consistently outperforms, thanks to its engineered design. As a leading crimped wire mesh manufacturer, JINJIU highlights how this difference transforms structural integrity, durability, and safety in construction projects.

Ordinary wire mesh relies on straight, uncrimped wires woven at right angles, offering basic functionality but lacking resilience. In building scenarios—like concrete reinforcement or safety barriers—its smooth wires can slip at intersections under load, leading to uneven stress distribution and potential failure. For example, when used as formwork for concrete slabs, ordinary mesh may deform under wet concrete weight, compromising structural precision.

Crimped wire mesh solves this with intentional crimps (indentations) pressed into wires at every intersection. This design locks wires in place, preventing slippage and creating a rigid, load-bearing structure. In concrete reinforcement, crimped woven wire mesh distributes tensile forces evenly across slabs, walls, and beams, reducing cracking and enhancing longevity. Its 4-8mm wire diameter (thicker than ordinary mesh) adds tensile strength, making it ideal for high-rise construction or heavy-duty flooring.

Durability is another key advantage. Stainless steel crimped wire mesh—a specialty of trusted crimped wire mesh manufacturer JINJIU—resists corrosion in humid concrete curing environments or outdoor applications (e.g., facade cladding). Unlike ordinary mesh, which may rust and weaken over time, its crimped design retains structural integrity even with minor corrosion, extending service life in coastal or industrial areas.

Building safety barriers benefits significantly. Ordinary mesh fences often sag or break under impact (e.g., from construction equipment), while crimped wire mesh’s rigid structure withstands force, protecting workers from falls or debris. Its uniform apertures (5-50mm) also prevent tool or material drops, a critical feature on scaffolding or elevated platforms.

Adaptability in building applications sets crimped woven wire mesh apart. It conforms to curved surfaces (e.g., arched doorways or circular columns) without losing strength, a flexibility ordinary mesh lacks. For screening aggregate in concrete mixing, its crimped design ensures consistent particle separation, avoiding blockages that plague ordinary mesh with irregular openings.

As a premier crimped wire mesh manufacturer, JINJIU delivers solutions where ordinary mesh falls short: stainless steel crimped wire mesh for coastal projects, heavy-gauge crimped wire mesh for industrial floors, and precision-woven variants for architectural facades. In building, it’s not just wire—it’s engineered reliability.