Description de la production

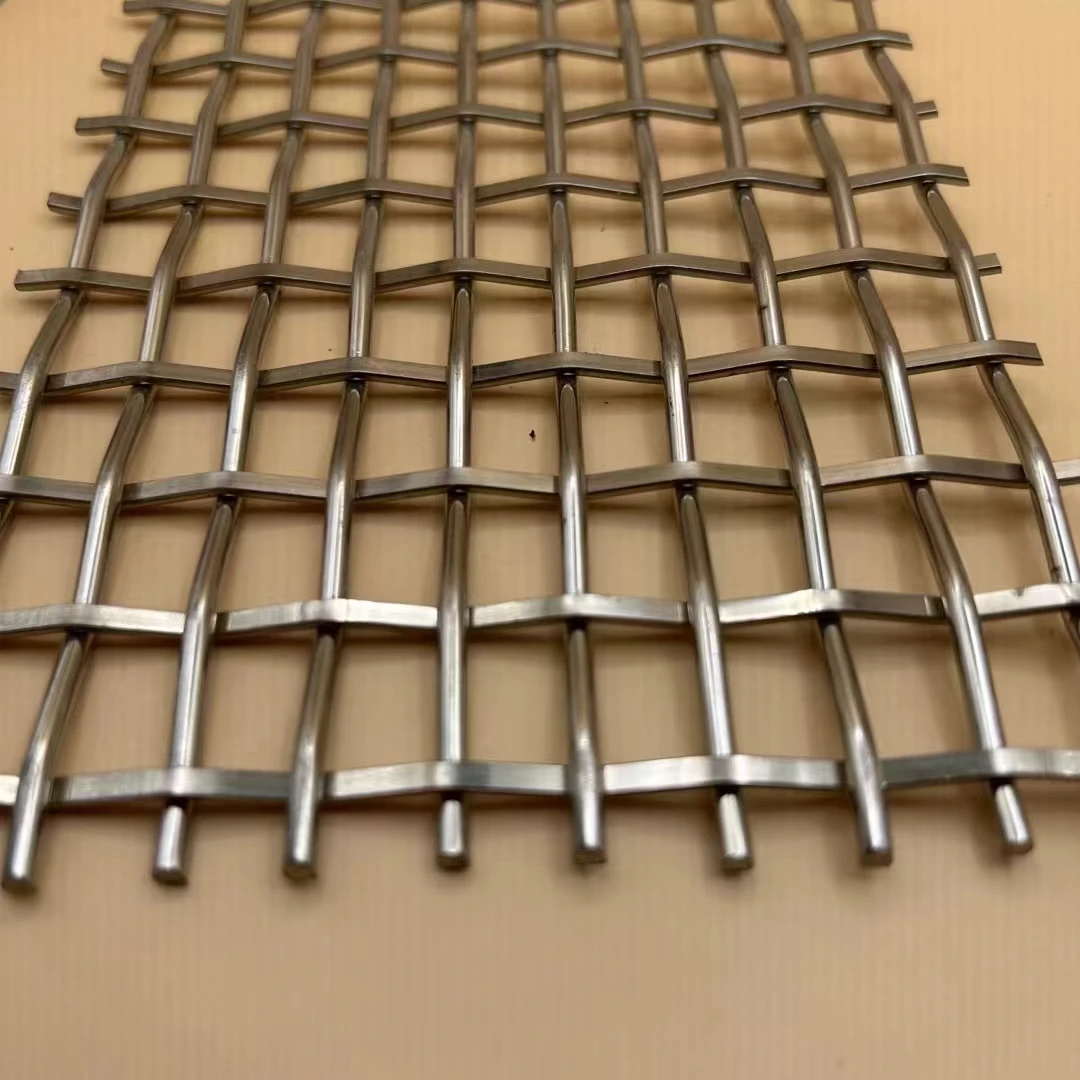

Sa résistance élevée à la traction, son excellente résistance aux vibrations et sa longue durée de vie lui permettent d'obtenir des résultats de criblage et des services précis au meilleur prix, de sorte que le treillis métallique bouclé 65MN est le choix parfait pour les cribles de concasseurs de roche et les cribles miniers.

|

Composition chimique du matériau 65MN

|

|

Matériel

|

C

|

Et

|

Mn

|

Cr

|

Dans

|

Avec

|

|

Acier 65Mn

Exemple : 6,5 mm

|

0.62-0.70

|

0.17-0.37

|

0.90-1.20

|

≤0.25

|

≤0.30

|

≤0.25

|

|

0.66

|

0.25

|

0.98

|

0.04

|

0.01

|

0.03

|

Différents types de bords Le matériau du treillis ondulé robuste est un fil d'acier à haute résistance, un fil d'acier 45#, un fil d'acier 65Mn. Il est généralement utilisé pour tamiser les pierres et le sable dans les mines et l'industrie du charbon. Les plaques de maille ont des bords différents.

Spécification

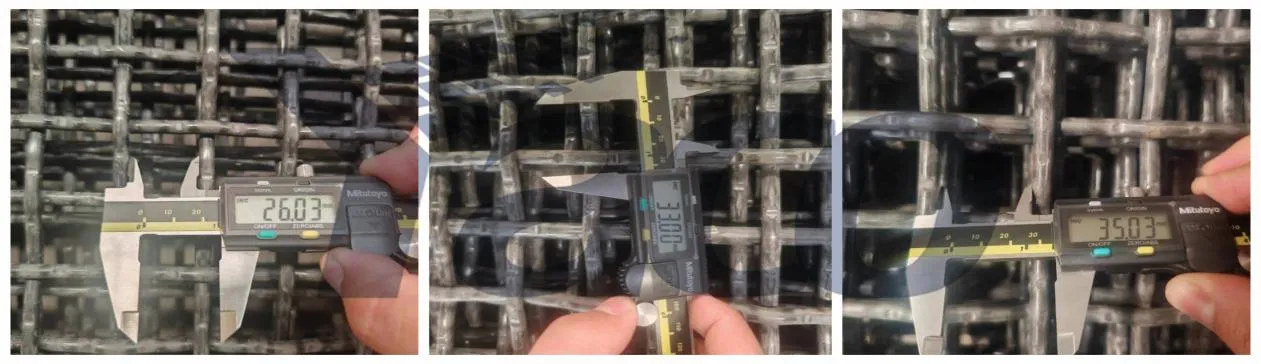

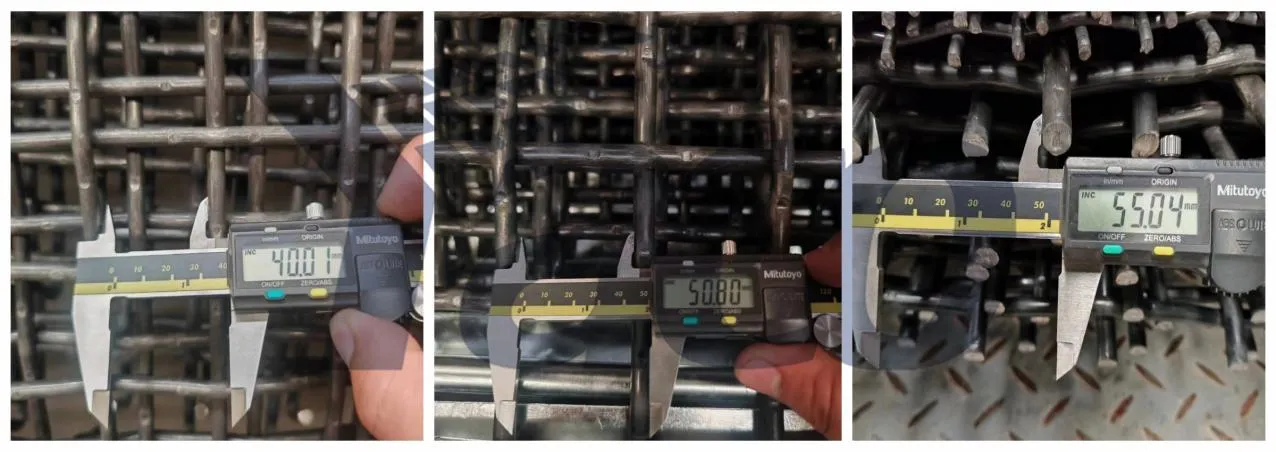

Nous pouvons personnaliser la taille du trou selon vos besoins

Écran vibrant à mailles métalliques ondulées, différentes tailles de trous :

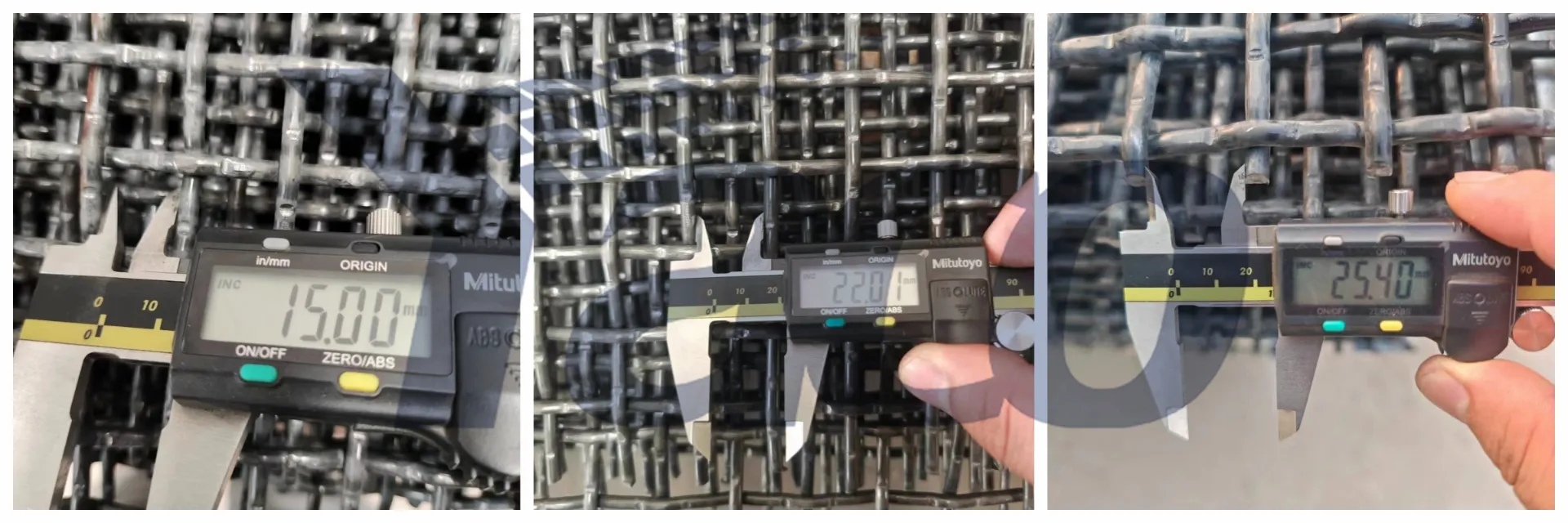

Détails de la maille du tamis vibrant

|

Matériel

|

Acier au manganèse à haute résistance.

|

|

Diamètre du fil

|

1,5 mm - 13 mm

|

|

Ouverture

|

2 mm - 110 mm.

|

|

Finition de surface

|

Finition au moulin, pulvérisation d'huile antirouille, revêtement PVC

|

|

Type de tissage

|

Sertissage double, sertissage intermédiaire, sertissage à sommet plat, sertissage à verrouillage

|

|

Taille

|

en feuille ou en rouleau, largeur jusqu'à 6 mètres, longueur jusqu'à 100 mètres.

|

Nous pouvons fournir différents types de treillis métalliques tissés : rouleaux de treillis métalliques ondulés, feuilles de treillis métalliques tissés, tamis vibrants avec ou sans crochets

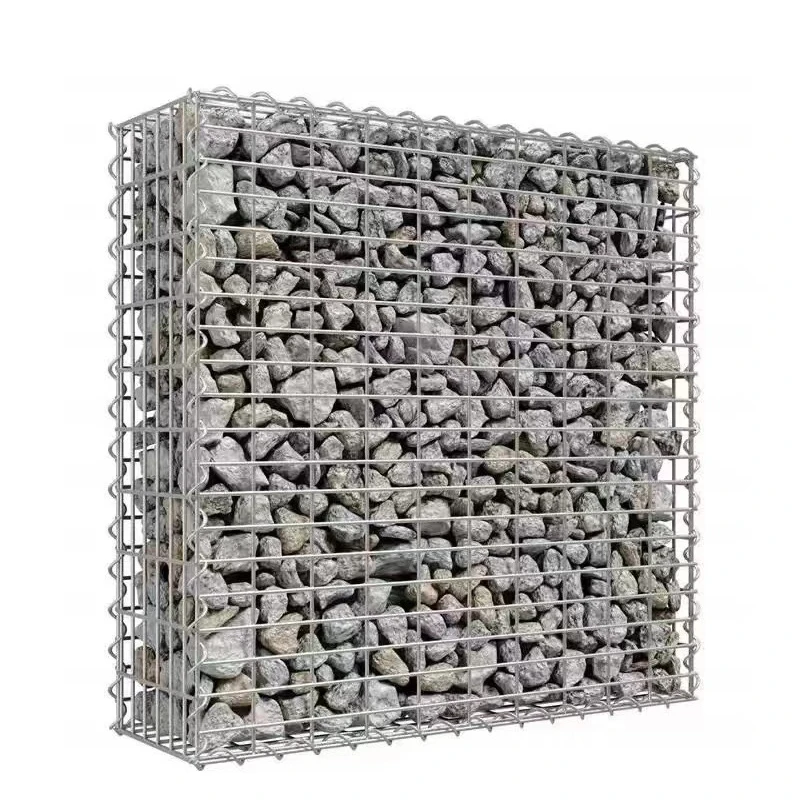

Application

Le tamis vibrant en acier au manganèse est largement utilisé dans l'exploitation minière, les carrières, l'industrie des agrégats pour tamiser différentes tailles de sable, de gravier, de charbon, de pierre, de roche, de matériaux métalliques et d'autres matériaux minéralisés.

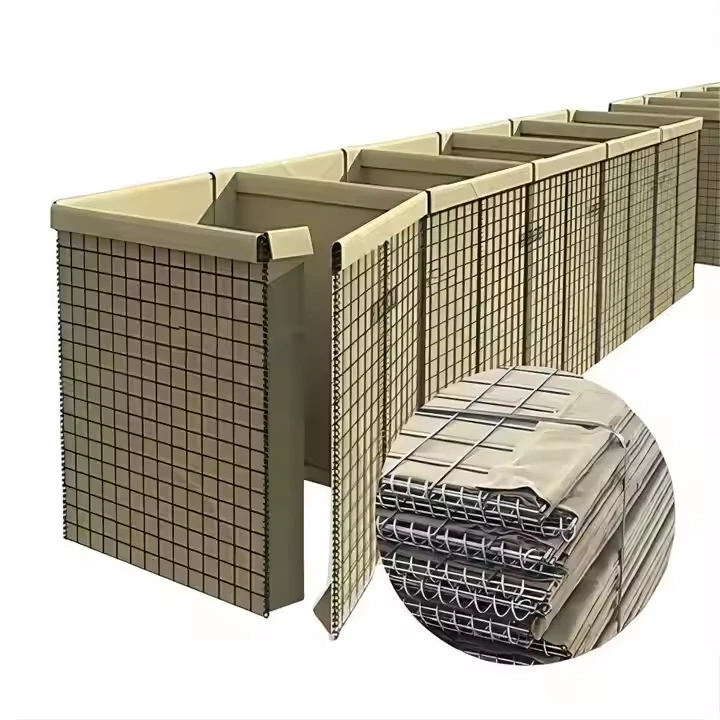

Notre treillis métallique ondulé est disponible dans une gamme de diamètres de fil et de tailles de mailles, vous permettant de choisir la solution idéale pour vos besoins spécifiques. Que vous ayez besoin d'une maille fine à des fins de filtration ou d'un calibre plus épais pour les clôtures de sécurité, nous avons la solution qui vous convient. La polyvalence de notre treillis métallique ondulé le rend adapté à un large éventail d'applications, notamment les enclos pour animaux, les éléments architecturaux et les barrières de protection.

En plus de sa résistance et de sa polyvalence, notre treillis métallique ondulé est également conçu pour une installation et un entretien faciles. Le treillis peut être facilement coupé à la taille souhaitée et est compatible avec divers systèmes de cadrage, garantissant une installation sans tracas. De plus, ses propriétés de résistance à la corrosion garantissent la longévité, même dans des environnements difficiles.

Crimped Weave Types: Double, Lock & Intermediate Crimp Differences

Crimped woven wire mesh owes its versatility to specialized weave patterns, with double, lock, and intermediate crimps catering to distinct industrial demands. As a leading crimped wire mesh manufacturer, JINJIU engineers each style to balance strength, flexibility, and durability—whether using carbon steel or stainless steel crimped wire mesh.

Double crimp, the most common variant, features uniform crimps pressed into both warp and weft wires at every intersection. This symmetrical design creates consistent square or rectangular apertures (5mm to 50mm), making crimped wire mesh ideal for general-purpose applications. Mining screens rely on their 3-6mm wire diameter to sift aggregates, while agricultural fencing uses it to contain livestock—its balanced structure resisting deformation under pressure. Stainless steel crimped wire mesh in double crimp excels in food processing, where corrosion resistance and easy cleaning are critical.

Lock crimp (or “interlock crimp”) elevates stability: wires are crimped to interlock at crossings, eliminating slippage even under heavy loads. This design suits high-stress environments, such as construction site safety barriers or heavy machinery guards. With apertures as small as 2mm, crimped woven wire mesh in lock crimp prevents debris penetration, while its rigid structure (using 4-8mm wires) withstands impact. Crimped wire mesh manufacturer JINJIU often recommends this type for industrial filtration, where consistent opening sizes are non-negotiable.

Intermediate crimp strikes a middle ground: warp wires have crimps at every intersection, while weft wires feature crimps at alternating points. This hybrid design offers flexibility without sacrificing strength, making it perfect for curved surfaces—like silo linings or cylindrical screens. Apertures range from 3mm to 30mm, with stainless steel crimped wire mesh variants thriving in chemical processing, where resistance to acids and temperature fluctuations is key. Its adaptability also shines in architectural applications, such as decorative facades, where form meets function.

Each weave type reflects crimped wire mesh’s engineered precision. As a trusted crimped wire mesh manufacturer, JINJIU tailors these patterns: double crimp for reliability, lock crimp for extreme strength, and intermediate crimp for versatility. Whether for mining, construction, or food safety, crimped woven wire mesh delivers—proving that the right crimp transforms performance.

Crimped vs. Ordinary Wire Mesh: Why It Excels in Building Applications

In building applications, the choice between crimped wire mesh and ordinary wire mesh hinges on performance under stress—and crimped woven wire mesh consistently outperforms, thanks to its engineered design. As a leading crimped wire mesh manufacturer, JINJIU highlights how this difference transforms structural integrity, durability, and safety in construction projects.

Ordinary wire mesh relies on straight, uncrimped wires woven at right angles, offering basic functionality but lacking resilience. In building scenarios—like concrete reinforcement or safety barriers—its smooth wires can slip at intersections under load, leading to uneven stress distribution and potential failure. For example, when used as formwork for concrete slabs, ordinary mesh may deform under wet concrete weight, compromising structural precision.

Crimped wire mesh solves this with intentional crimps (indentations) pressed into wires at every intersection. This design locks wires in place, preventing slippage and creating a rigid, load-bearing structure. In concrete reinforcement, crimped woven wire mesh distributes tensile forces evenly across slabs, walls, and beams, reducing cracking and enhancing longevity. Its 4-8mm wire diameter (thicker than ordinary mesh) adds tensile strength, making it ideal for high-rise construction or heavy-duty flooring.

Durability is another key advantage. Stainless steel crimped wire mesh—a specialty of trusted crimped wire mesh manufacturer JINJIU—resists corrosion in humid concrete curing environments or outdoor applications (e.g., facade cladding). Unlike ordinary mesh, which may rust and weaken over time, its crimped design retains structural integrity even with minor corrosion, extending service life in coastal or industrial areas.

Building safety barriers benefits significantly. Ordinary mesh fences often sag or break under impact (e.g., from construction equipment), while crimped wire mesh’s rigid structure withstands force, protecting workers from falls or debris. Its uniform apertures (5-50mm) also prevent tool or material drops, a critical feature on scaffolding or elevated platforms.

Adaptability in building applications sets crimped woven wire mesh apart. It conforms to curved surfaces (e.g., arched doorways or circular columns) without losing strength, a flexibility ordinary mesh lacks. For screening aggregate in concrete mixing, its crimped design ensures consistent particle separation, avoiding blockages that plague ordinary mesh with irregular openings.

As a premier crimped wire mesh manufacturer, JINJIU delivers solutions where ordinary mesh falls short: stainless steel crimped wire mesh for coastal projects, heavy-gauge crimped wire mesh for industrial floors, and precision-woven variants for architectural facades. In building, it’s not just wire—it’s engineered reliability.