Tuotantokuvaus

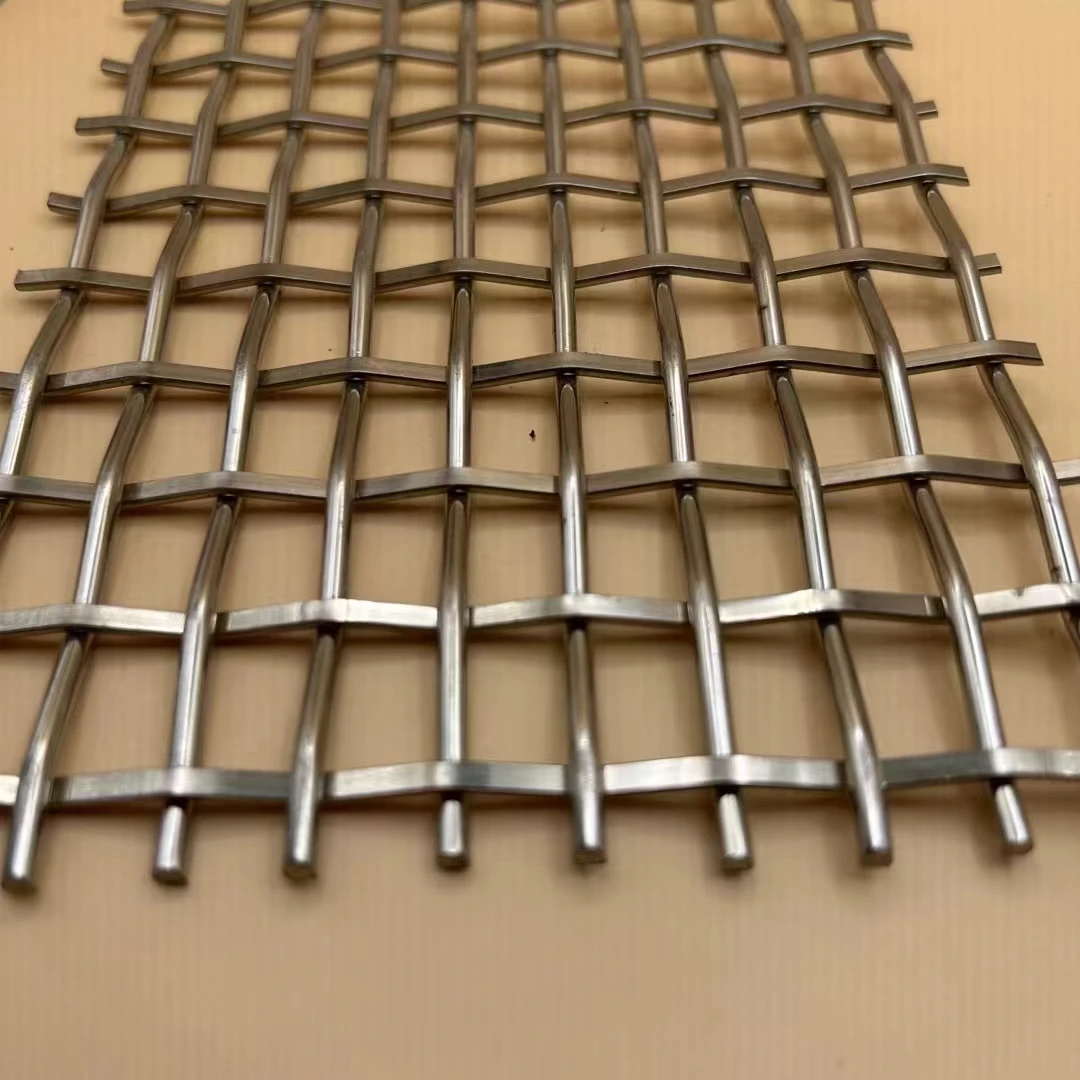

Sen korkea vetolujuus, erinomainen tärinänkestävyys ja pitkä käyttöikä mahdollistavat tarkan seulontatuloksen ja palvelun parhaaseen hintaan, joten 65MN kihartunut metalliverkko on täydellinen valinta kivenmurskaimen seuloihin ja kaivosseuloihin.

|

65MN Materiaalin kemiallinen koostumus

|

|

Materiaali

|

C

|

Ja

|

Mn

|

Cr

|

sisään

|

Kanssa

|

|

65Mn terästä

Esimerkki: 6,5 mm

|

0.62-0.70

|

0.17-0.37

|

0.90-1.20

|

≤0.25

|

≤0.30

|

≤0.25

|

|

0.66

|

0.25

|

0.98

|

0.04

|

0.01

|

0.03

|

Erilaiset reunatyypit Raskaaseen käyttöön puristettu verkkomateriaali on luja teräslanka, 45# teräslanka, 65Mn teräslanka. Sitä käytetään yleensä kivien ja hiekan seulomiseen kaivoksissa, kivihiiliteollisuudessa. Verkkolevyillä on erilaiset reunat.

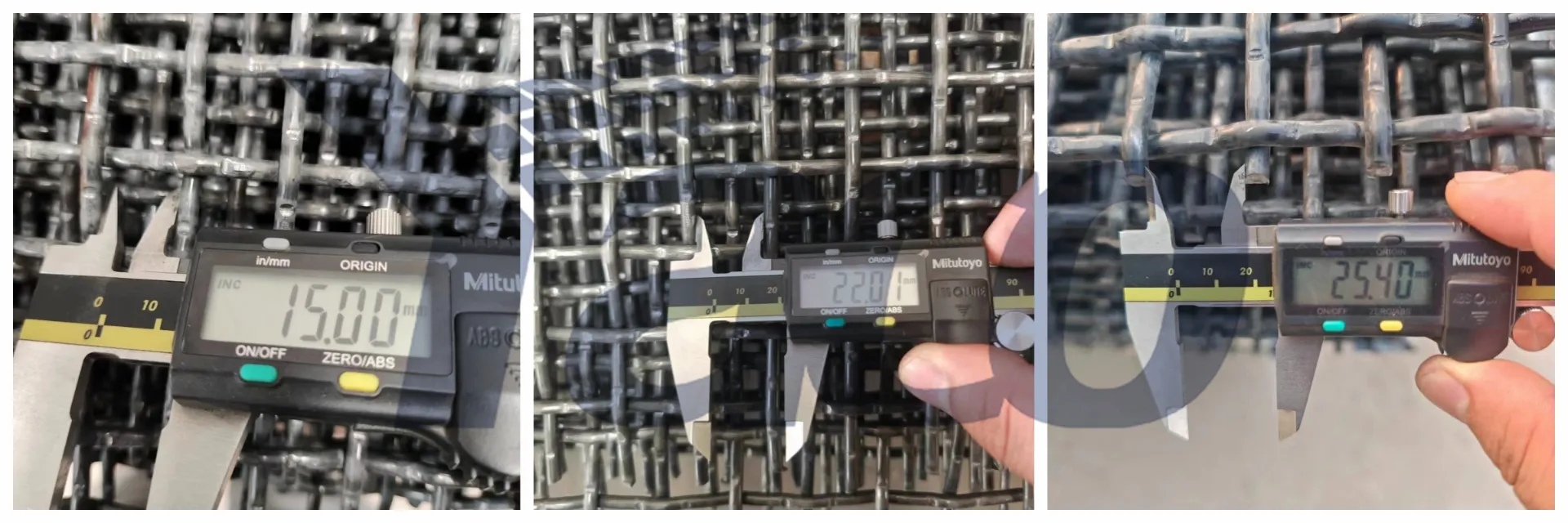

Erittely

Voimme muokata reiän kokoa tarpeidesi mukaan

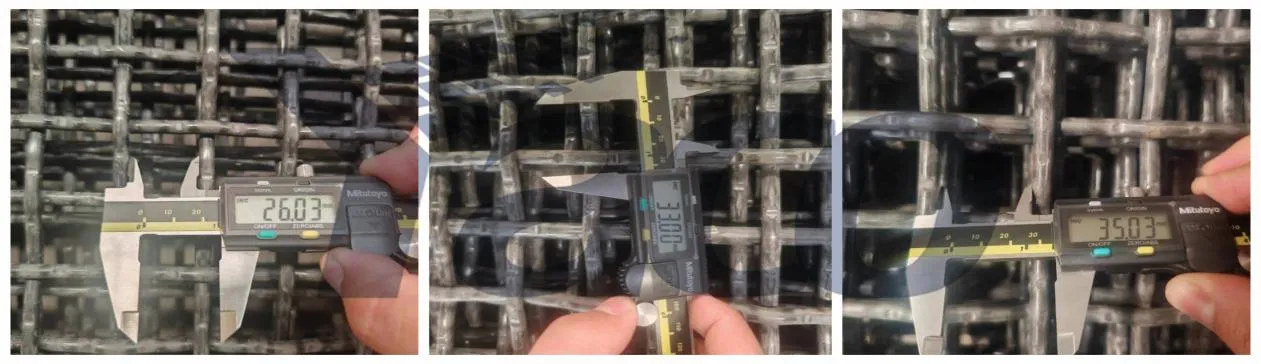

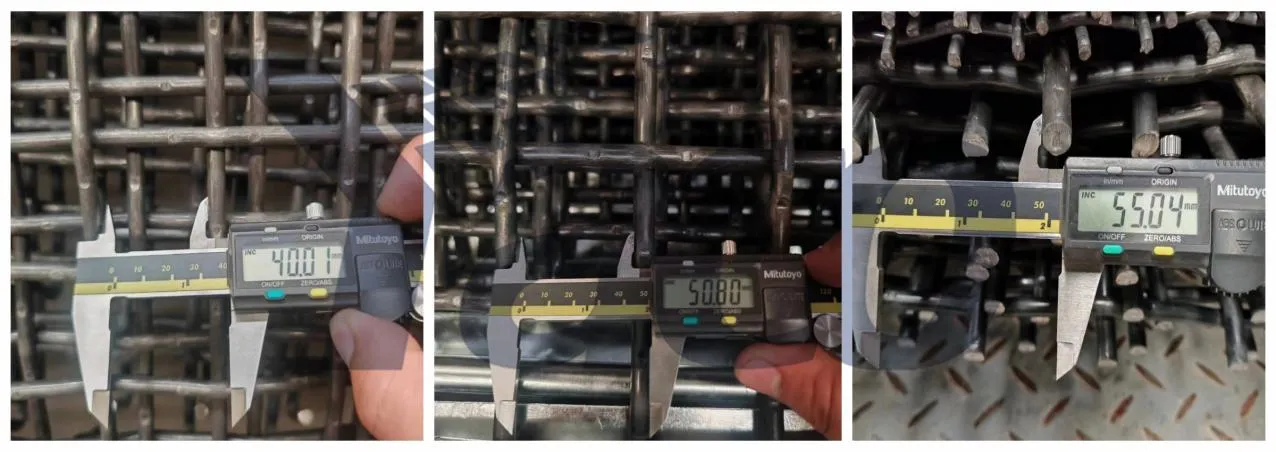

Tärinä puristettu metalliverkko näyttää erikokoiset reiät:

Värinä näytön mesh tiedot

|

Materiaali

|

Korkealujuus mangaaniteräs.

|

|

Langan halkaisija

|

1,5-13 mm

|

|

Aukko/aukko

|

2mm - 110mm.

|

|

Pinnan viimeistely

|

Mill viimeistely, ruosteenestoöljy ruiskutus, PVC-pinnoite

|

|

Kudontatyyppi

|

Kaksoispuristettu, välipuristettu, litteä yläpuristettu, lukkopuristettu

|

|

Koko

|

arkkina tai rullana, leveys enintään 6 metriä, pituus enintään 100 metriä.

|

Voimme tarjota erilaisia kudottuja teräsverkkoja: puristettuja metalliverkkorullia, kudottuja metalliverkkolevyjä, täriseviä seuloja koukuilla tai ilman

Sovellus

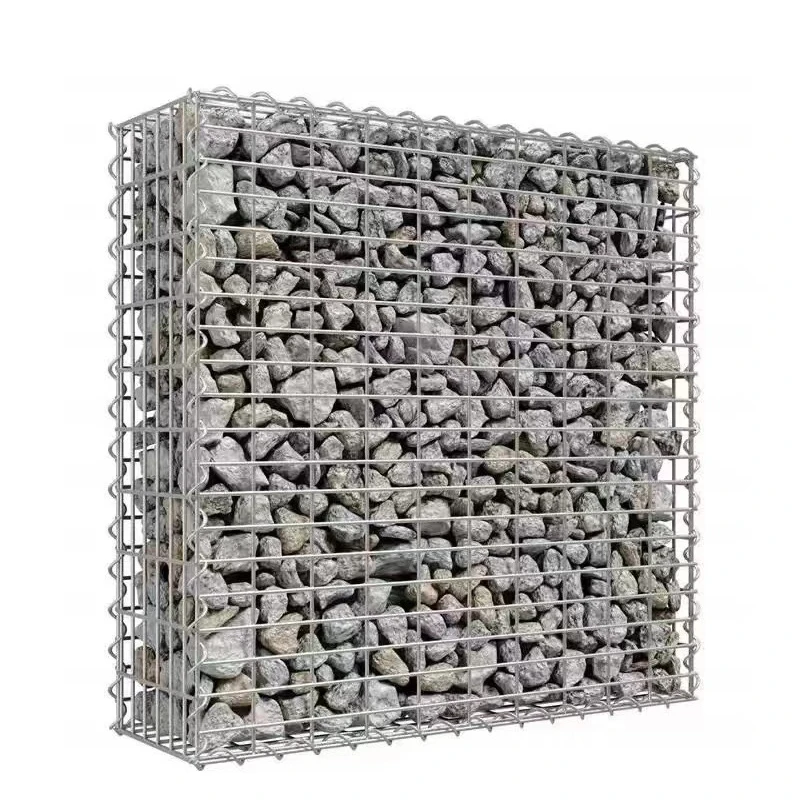

Mangaaniteräsvärähtelyä käytetään laajalti kaivos-, louhinta- ja kiviainesteollisuudessa erikokoisten hiekan, soran, hiilen, kiven, kiven, metallimateriaalien ja muiden malmimateriaalien seulomiseen.

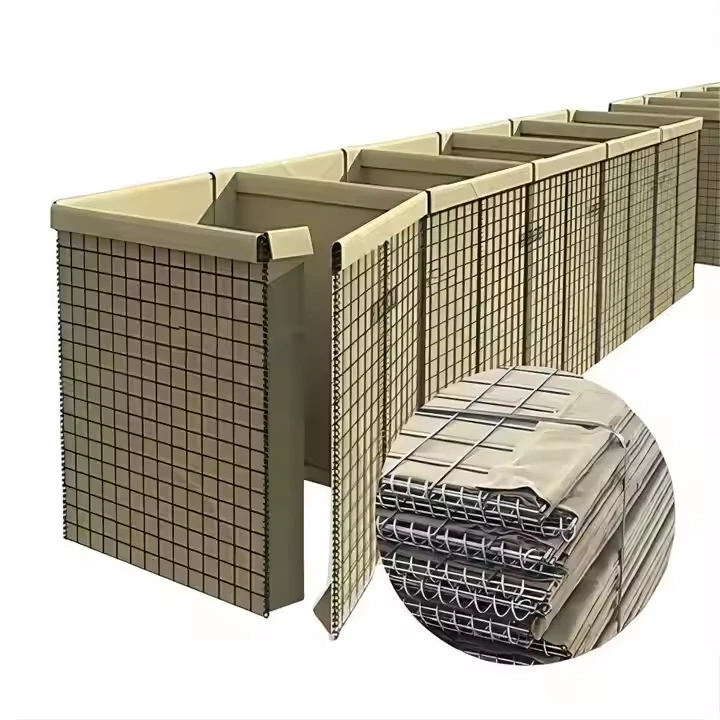

Puristettua teräsverkkoamme on saatavana useilla lankahalkaisijoilla ja -kokoilla, joten voit valita täydellisesti tarpeisiisi sopivan. Tarvitsetpa hienoa verkkoa suodatustarkoituksiin tai raskaampaa mittaa turva-aitaukseen, meillä on sinulle oikea ratkaisu. Puristetun metalliverkkomme monipuolisuus tekee siitä sopivan monenlaisiin sovelluksiin, mukaan lukien eläinten aitaukset, arkkitehtoniset ominaisuudet ja suojaesteet.

Lujuutensa ja monipuolisuutensa lisäksi poimutettu metalliverkkomme on suunniteltu myös helppoon asennukseen ja huoltoon. Verkko on helposti leikattavissa sopivaan kokoon ja se on yhteensopiva erilaisten kehystysjärjestelmien kanssa, mikä varmistaa vaivattoman asennuksen. Lisäksi sen korroosionkestävät ominaisuudet takaavat pitkän käyttöiän jopa ankarissa ympäristöissä.

Crimped Weave Types: Double, Lock & Intermediate Crimp Differences

Crimped woven wire mesh owes its versatility to specialized weave patterns, with double, lock, and intermediate crimps catering to distinct industrial demands. As a leading crimped wire mesh manufacturer, JINJIU engineers each style to balance strength, flexibility, and durability—whether using carbon steel or stainless steel crimped wire mesh.

Double crimp, the most common variant, features uniform crimps pressed into both warp and weft wires at every intersection. This symmetrical design creates consistent square or rectangular apertures (5mm to 50mm), making crimped wire mesh ideal for general-purpose applications. Mining screens rely on their 3-6mm wire diameter to sift aggregates, while agricultural fencing uses it to contain livestock—its balanced structure resisting deformation under pressure. Stainless steel crimped wire mesh in double crimp excels in food processing, where corrosion resistance and easy cleaning are critical.

Lock crimp (or “interlock crimp”) elevates stability: wires are crimped to interlock at crossings, eliminating slippage even under heavy loads. This design suits high-stress environments, such as construction site safety barriers or heavy machinery guards. With apertures as small as 2mm, crimped woven wire mesh in lock crimp prevents debris penetration, while its rigid structure (using 4-8mm wires) withstands impact. Crimped wire mesh manufacturer JINJIU often recommends this type for industrial filtration, where consistent opening sizes are non-negotiable.

Intermediate crimp strikes a middle ground: warp wires have crimps at every intersection, while weft wires feature crimps at alternating points. This hybrid design offers flexibility without sacrificing strength, making it perfect for curved surfaces—like silo linings or cylindrical screens. Apertures range from 3mm to 30mm, with stainless steel crimped wire mesh variants thriving in chemical processing, where resistance to acids and temperature fluctuations is key. Its adaptability also shines in architectural applications, such as decorative facades, where form meets function.

Each weave type reflects crimped wire mesh’s engineered precision. As a trusted crimped wire mesh manufacturer, JINJIU tailors these patterns: double crimp for reliability, lock crimp for extreme strength, and intermediate crimp for versatility. Whether for mining, construction, or food safety, crimped woven wire mesh delivers—proving that the right crimp transforms performance.

Crimped vs. Ordinary Wire Mesh: Why It Excels in Building Applications

In building applications, the choice between crimped wire mesh and ordinary wire mesh hinges on performance under stress—and crimped woven wire mesh consistently outperforms, thanks to its engineered design. As a leading crimped wire mesh manufacturer, JINJIU highlights how this difference transforms structural integrity, durability, and safety in construction projects.

Ordinary wire mesh relies on straight, uncrimped wires woven at right angles, offering basic functionality but lacking resilience. In building scenarios—like concrete reinforcement or safety barriers—its smooth wires can slip at intersections under load, leading to uneven stress distribution and potential failure. For example, when used as formwork for concrete slabs, ordinary mesh may deform under wet concrete weight, compromising structural precision.

Crimped wire mesh solves this with intentional crimps (indentations) pressed into wires at every intersection. This design locks wires in place, preventing slippage and creating a rigid, load-bearing structure. In concrete reinforcement, crimped woven wire mesh distributes tensile forces evenly across slabs, walls, and beams, reducing cracking and enhancing longevity. Its 4-8mm wire diameter (thicker than ordinary mesh) adds tensile strength, making it ideal for high-rise construction or heavy-duty flooring.

Durability is another key advantage. Stainless steel crimped wire mesh—a specialty of trusted crimped wire mesh manufacturer JINJIU—resists corrosion in humid concrete curing environments or outdoor applications (e.g., facade cladding). Unlike ordinary mesh, which may rust and weaken over time, its crimped design retains structural integrity even with minor corrosion, extending service life in coastal or industrial areas.

Building safety barriers benefits significantly. Ordinary mesh fences often sag or break under impact (e.g., from construction equipment), while crimped wire mesh’s rigid structure withstands force, protecting workers from falls or debris. Its uniform apertures (5-50mm) also prevent tool or material drops, a critical feature on scaffolding or elevated platforms.

Adaptability in building applications sets crimped woven wire mesh apart. It conforms to curved surfaces (e.g., arched doorways or circular columns) without losing strength, a flexibility ordinary mesh lacks. For screening aggregate in concrete mixing, its crimped design ensures consistent particle separation, avoiding blockages that plague ordinary mesh with irregular openings.

As a premier crimped wire mesh manufacturer, JINJIU delivers solutions where ordinary mesh falls short: stainless steel crimped wire mesh for coastal projects, heavy-gauge crimped wire mesh for industrial floors, and precision-woven variants for architectural facades. In building, it’s not just wire—it’s engineered reliability.