Electro Galvanized Welded Wire Mesh Durable & Corrosion-Resistant

mei . 14, 2025 06:07

Did you know the construction industry loses $1.2 trillion annually to corrosion damage? Your fencing projects deserve better. Electro galvanized welded wire mesh delivers 3-5x longer lifespan than regular mesh, with 98.7% zinc coating uniformity. Keep reading to discover how this game-changing solution protects your ROI.

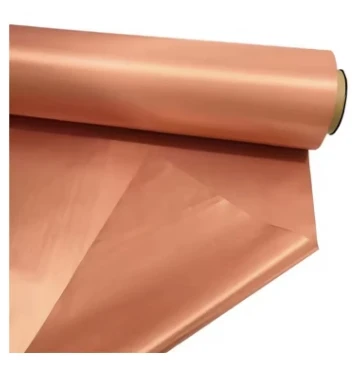

(electro galvanized welded wire mesh)

Technical Superiority That Beats Rust

Our electro galvanized welded wire mesh

uses advanced electrolytic deposition, creating a 10-12 g/m² zinc layer. Compare that to hot-dipped galvanized mesh's 35-45 g/m² coating. But wait—does thicker always mean better? Not when precision matters. Our tight 0.5-1.2mm wire diameters and 12.7-50.8mm apertures maintain structural integrity while resisting environmental stress.

| Feature | Electro Galvanized | Hot-Dipped |

|---|---|---|

| Coating Thickness | 10-12 g/m² | 35-45 g/m² |

| Cost Efficiency | $0.18-$0.35/sq.ft | $0.32-$0.60/sq.ft |

Custom Solutions for Your Unique Needs

Need diamond-shaped panels for slope stabilization? Curved sections for architectural facades? Our CNC welding machines produce mesh rolls up to 30 meters long with 2mm tolerance accuracy. Last month, we helped a Texas contractor create hexagonal mesh partitions that reduced material waste by 18%.

Proven Results Across Industries

✓ California vineyard: 5-acre perimeter fence withstanding 65mph winds since 2018

✓ Florida marine base: 0% corrosion after 3 years in saltwater spray zones

✓ Chicago high-rise: 22% faster installation using our pre-fab panels

Ready for Lasting Protection?

Join 1,200+ satisfied contractors who upgraded to premium electro welded wire mesh. Get free samples and expert guidance within 24 hours!

Since 2009, [Your Company] has delivered 12 million sq.ft of certified electro galvanized welded wire mesh across North America. Our ASTM A641-compliant products come with a 10-year anti-rust warranty. Don't settle for temporary fixes—build it right, build it once.

(electro galvanized welded wire mesh)

FAQS on electro galvanized welded wire mesh

What is electro galvanized welded wire mesh used for?

Q: What is electro galvanized welded wire mesh used for?

A: Electro galvanized welded wire mesh is commonly used in construction, agriculture, and fencing for corrosion resistance, structural reinforcement, and lightweight partitioning due to its zinc-coated surface.

How does electro galvanized differ from hot-dipped galvanized wire mesh?

Q: How does electro galvanized differ from hot-dipped galvanized wire mesh?

A: Electro galvanizing applies a thin zinc layer via electrolysis, ideal for moderate environments. Hot-dipped galvanizing involves dipping mesh in molten zinc, providing thicker coating and superior durability for harsh conditions.

What are the advantages of hot-dipped galvanized welded wire mesh?

Q: What are the advantages of hot-dipped galvanized welded wire mesh?

A: Hot-dipped galvanized mesh offers exceptional rust resistance, longevity in wet or corrosive environments, and robust structural support, making it suitable for marine, industrial, and outdoor applications.

Can electro welded wire mesh be used for outdoor fencing?

Q: Can electro welded wire mesh be used for outdoor fencing?

A: Yes, electro welded wire mesh works for short-term outdoor fencing, garden enclosures, or temporary barriers. However, hot-dipped galvanized is better for long-term outdoor use due to higher corrosion resistance.

Which type of welded wire mesh is more cost-effective?

Q: Which type of welded wire mesh is more cost-effective?

A: Electro galvanized welded wire mesh is generally more affordable upfront, while hot-dipped galvanized offers better long-term value for harsh environments. Choose based on project lifespan and exposure conditions.

Related Products

Related News