Precision Square Weave Mesh for Filtration & Screening

aug . 10, 2025 07:20

The Unrivaled Precision and Versatility of square weave mesh in Industrial Applications

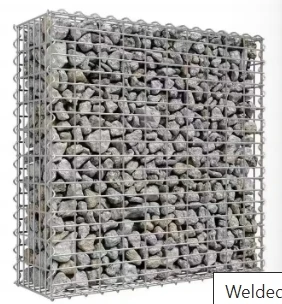

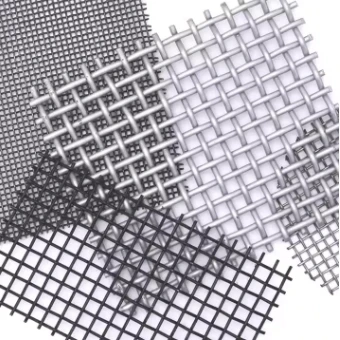

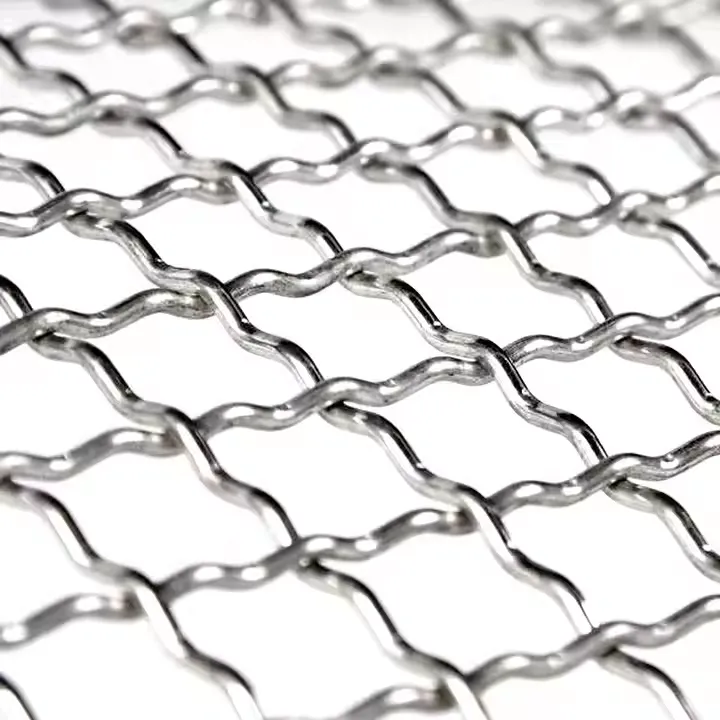

In the highly demanding landscape of modern industrial operations, the selection of appropriate materials and components is paramount to ensuring efficiency, safety, and long-term operational integrity. Among the myriad of filtration and separation media available, square weave mesh stands out as a foundational, indispensable element due to its unique structural integrity, precise aperture control, and exceptional versatility. Unlike other mesh types such as dutch mesh or dutch weave mesh, which offer specific filtration characteristics often suited for high-pressure or fine filtration needs with their distinct warp and weft wire configurations creating a tapered or tortuous path, square weave mesh features equally spaced warp and weft wires that are woven in an over-and-under pattern, forming precise square openings. This fundamental design ensures a consistent and predictable open area, making it ideal for a vast array of applications requiring precise particle sizing, robust material support, or efficient fluid dynamics. Its applications span across critical sectors including petrochemical, pharmaceutical, mining, food and beverage, and water treatment, where its performance directly impacts product purity, operational uptime, and adherence to stringent regulatory standards. The enduring demand for high-quality square weave mesh underscores its significance as a core component in industrial processes that rely on dependable separation and filtration capabilities. This comprehensive article delves deep into the manufacturing intricacies, technical specifications, diverse applications, and inherent advantages of square weave mesh, providing B2B decision-makers and technical professionals with the insights necessary to make informed procurement and engineering choices. We will explore the rigorous quality control measures, the benefits of bespoke customization, and the expert support offered by leading manufacturers like Jinjiu Wire Mesh, ensuring that every deployment of this vital material contributes to enhanced operational excellence and sustainable industrial growth. The strategic adoption of superior square weave mesh solutions is not merely about sourcing a product; it is about investing in precision, reliability, and a long-term partnership that underpins the success of complex industrial systems globally.

The Meticulous Manufacturing Process of Square Weave Mesh: From Raw Material to Precision Product

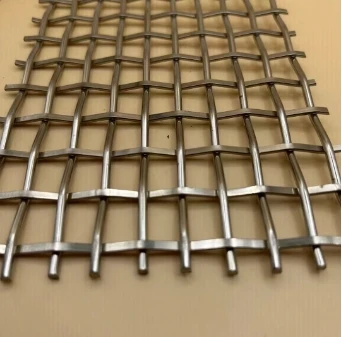

The production of high-quality square weave mesh is a sophisticated process that demands exceptional precision and adherence to rigorous quality standards at every stage, commencing with the meticulous selection of raw materials. The choice of material is critical, as it dictates the mesh’s ultimate performance characteristics, including corrosion resistance, tensile strength, thermal stability, and overall service life. Common materials include various grades of stainless steel (such as AISI 304, 316, and 316L, renowned for their excellent corrosion resistance in diverse chemical environments), galvanized steel (offering enhanced corrosion protection through a zinc coating), carbon steel (valued for its strength and cost-effectiveness in less demanding applications), and specialized alloys like nickel, copper, and titanium, which are utilized for unique requirements such as extreme temperatures or highly aggressive chemical media. The manufacturing journey typically begins with wire drawing, where rods of selected metal are drawn through a series of dies to achieve precise wire diameters, ranging from ultra-fine to robust gauges, which are critical for controlling the mesh aperture and strength. Following wire preparation, the core of the process is weaving, predominantly carried out on advanced automated looms. For square weave mesh, the plain weave pattern is most common, where each warp wire (running lengthwise) passes alternately over and under each weft wire (running crosswise), and vice versa. This creates equally sized square openings and ensures uniform tension and stability across the mesh surface. Less frequently, for specific strength or filtration needs, a twill square weave might be employed, where each warp wire passes over two weft wires and then under two, shifting one thread after each pass, resulting in a diagonal pattern and greater strength for heavier wires, though still maintaining square apertures. The precision of these weaving looms, often CNC-controlled, is paramount to maintaining consistent mesh count and aperture sizes, which directly impacts filtration accuracy and flow rates. After weaving, the mesh undergoes a series of crucial post-processing stages. These can include annealing (heat treatment to relieve internal stresses and enhance ductility), flattening or calendering (to ensure a uniform thickness and smooth surface), and precision cutting to specified dimensions and shapes, from large rolls to custom-fabricated panels, discs, or cylinders.

Quality control is integrated throughout the entire manufacturing cycle, not merely as a final inspection step. Each batch of raw material undergoes spectral analysis to verify its chemical composition. During wire drawing, continuous laser micrometers monitor wire diameter for minute deviations. Post-weaving, advanced optical systems and manual inspections verify mesh count, aperture size, and wire spacing against stringent international standards such as ISO 9001 (for quality management systems), ASTM E2016 (Standard Guide for Industrial Woven Wire Cloth), and ANSI/AWS (for welding standards if fabrication is involved). Tensile strength tests, elongation tests, and corrosion resistance tests (e.g., salt spray tests for stainless steel) are regularly conducted on samples to ensure the mechanical and chemical integrity of the finished square weave mesh. For applications in highly regulated industries like pharmaceutical or food processing, additional certifications like FDA compliance might be required, necessitating even more rigorous testing for material purity and surface finish. The expected service life of square weave mesh is highly variable, depending on the material, operational environment (temperature, pressure, corrosive agents, abrasive particles), and frequency of cleaning. However, with proper material selection and manufacturing quality, a lifespan ranging from several years to decades is common, underscoring its cost-effectiveness over time. This meticulous production protocol ensures that the final square weave mesh product delivers consistent, reliable performance in the most demanding industrial settings. For instance, in the petrochemical sector, square weave mesh filters are critical for catalyst retention and contaminant removal, where their precise apertures ensure optimal reaction efficiency and prevent downstream equipment damage. In the metallurgy industry, the mesh is indispensable for screening and sizing ores and powders, directly impacting product quality and processing efficiency. For water and wastewater treatment, its robust construction and consistent opening allow for effective removal of suspended solids, contributing to cleaner effluent and more efficient system operation. The inherent advantages of using high-quality square weave mesh in these typical applications include significant energy savings due to minimal pressure drop across filter media, superior corrosion resistance prolonging equipment life, and the ability to maintain precise separation even under arduous conditions, leading to enhanced productivity and reduced maintenance overheads. This detailed understanding of the manufacturing process and its inherent quality checkpoints instills confidence in the product's reliability and performance.

Technical Parameters and Specifications of Square Weave Mesh: A Comprehensive Overview

Understanding the detailed technical parameters of square weave mesh is crucial for engineers and procurement specialists to specify the correct product for a given application, ensuring optimal performance and cost-effectiveness. These parameters define the physical and filtration characteristics of the mesh, directly impacting its suitability for various industrial processes. The mesh count, perhaps the most fundamental parameter, refers to the number of openings per linear inch, measured from the center of one wire to the center of an adjacent wire. A higher mesh count indicates smaller apertures and finer filtration. For instance, a 100 mesh square weave mesh has 100 openings per inch, implying a much finer separation capability than a 20 mesh. Closely related is the wire diameter, which is the thickness of the individual wires used in the weaving process. Wire diameter significantly influences the mesh's strength, durability, and open area. Thicker wires provide greater mechanical strength and resistance to wear, making them suitable for heavy-duty screening or support applications, but they also reduce the open area and consequently the flow rate. Conversely, thinner wires maximize open area, facilitating higher flow rates, but at the expense of strength. The aperture size, or opening size, is the clear space between adjacent parallel wires. This dimension directly determines the smallest particle that can pass through the mesh. It is inversely proportional to the mesh count and depends on the wire diameter. Precise aperture control is a hallmark of high-quality square weave mesh and is critical for accurate particle sizing and consistent filtration efficiency. The material composition, as discussed, is another pivotal parameter, with options like stainless steel (304, 316, 316L), galvanized steel, carbon steel, and various alloys chosen based on the required corrosion resistance, temperature stability, and mechanical properties. The weave type, while primarily plain weave for standard square mesh, can sometimes include twill square weave for enhanced strength or specific filtration patterns.

The open area percentage is a vital characteristic, representing the total area of the mesh openings as a percentage of the total mesh area. A higher open area allows for greater flow rates and reduced pressure drop, which translates to energy savings and improved process efficiency. For example, a mesh with 50% open area will allow twice the flow compared to a mesh with 25% open area, assuming the same pressure differential. This parameter is calculated based on the mesh count and wire diameter and is a critical consideration for fluid handling and pneumatic conveying systems. Dimensional tolerances, referring to the permissible variations in mesh count, wire diameter, and overall panel/roll dimensions, are essential for ensuring consistency and interchangeability, especially in precision applications where fit and function are critical. Reputable manufacturers adhere to strict ISO and ASTM standards for these tolerances. Form factor, whether it's rolls, sheets, cut-to-size pieces, or fabricated components like cylinders or baskets, also forms part of the specification, tailored to the end-use application. Beyond these core parameters, additional considerations include the surface finish (e.g., smooth, polished, or electropolished for pharmaceutical or food-grade applications to prevent bacterial growth and facilitate cleaning), edge treatment (e.g., selvage edge, raw cut edge, or reinforced edge), and specific certifications required by regulated industries. For specialized filtration needs, while square weave mesh offers precise square openings, related woven wire products like dutch weave wire mesh, with its distinct weave pattern and typically denser structure, might be considered for extremely fine filtration or high-pressure applications where a tortuous path filtration mechanism is desired. However, for most general industrial filtration, screening, and support applications where clear, consistent openings are paramount, the precision and predictable performance of square weave mesh remain unparalleled. Understanding this intricate interplay of parameters allows for the precise specification of square weave mesh, guaranteeing optimal performance, efficiency, and longevity in demanding industrial environments.

Typical Square Weave Mesh Parameters

| Parameter | Common Range/Value | Significance |

|---|---|---|

| Mesh Count (per inch) | 2 to 635 | Defines fineness of openings; higher count means finer filtration. |

| Wire Diameter (mm) | 0.025 to 6.35 | Influences strength, durability, and open area. |

| Aperture Size (mm / micron) | 0.021 to 12.7 | Precise opening size for particle separation. |

| Material | SS 304, 316, 316L; Galvanized; Carbon Steel; Nickel Alloys | Determines corrosion resistance, temperature range, strength. |

| Weave Type | Plain Weave (Standard), Twill Square Weave | Affects stability, strength, and filtration characteristics. |

| Open Area (%) | Typically 25% to 70% | Impacts flow rate, pressure drop, and filtration capacity. |

| Roll Width (m) | 0.914 to 1.524 (36" to 60") | Standard dimensions for industrial applications. |

| Roll Length (m) | 15 to 30 (50' to 100') | Standard lengths for bulk supply. |

| Tolerance | +/- 5% on aperture/wire diameter (per ASTM E2016) | Ensures consistency and precise fit for demanding uses. |

Diverse Application Scenarios and Proven Case Studies of Square Weave Mesh

The inherent versatility and precision of square weave mesh enable its widespread application across an impressive array of industrial sectors, addressing critical needs for separation, filtration, support, and protection. In the petrochemical industry, square weave mesh is extensively used in catalyst support grids within reactors, ensuring the uniform flow of reactants while preventing catalyst material loss. It also functions as a crucial component in pressure filters, strainers, and fluidizing beds, effectively removing particulate matter from oils, gases, and chemical solutions, thereby protecting downstream equipment and maintaining product purity. For instance, a major chemical plant utilizing our 316L stainless steel square weave mesh in their catalytic cracking units reported a 15% reduction in unscheduled downtime due to reduced fouling and extended catalyst life, a testament to the mesh's robust performance in high-temperature, corrosive environments. In the mining and aggregate industry, the mesh is indispensable for screening and sizing various minerals, sands, gravels, and ores. Its consistent aperture size ensures precise particle classification, which is vital for product quality and efficient resource utilization. From heavy-duty quarry screens made of high-carbon steel square weave mesh to finer screens for silica sand processing, its durability and resistance to abrasion are key performance indicators. One large-scale mining operation transitioned from less durable screens to Jinjiu's specialized abrasion-resistant square weave mesh, resulting in a 30% increase in screen lifespan and a noticeable improvement in the consistency of their graded materials, directly impacting their bottom line.

The food and beverage industry relies on hygienic and precise filtration, where stainless steel square weave mesh (typically 304 or 316L grades) is employed in processes such as juice clarification, brewing, sugar refining, and grain drying. Its smooth surface finish, absence of crevices, and resistance to corrosion and bacterial growth make it ideal for contact with consumables, meeting stringent FDA and HACCP standards. A prominent brewery, for example, implemented our fine square weave mesh filters in their beer clarification system and achieved superior product clarity and extended shelf life, earning positive feedback from both quality control and customers. The pharmaceutical industry demands even higher levels of purity and precision. Here, ultra-fine square weave mesh, often electropolished for enhanced hygiene and ease of cleaning, is used in tablet pressing, powder sieving, and sterile filtration. Its consistent openings ensure precise particle size control, crucial for drug efficacy and safety. In the water and wastewater treatment sector, square weave mesh serves as a primary filtration medium for removing suspended solids, debris, and larger particulates from municipal and industrial water streams. Its robust construction allows it to withstand significant flow rates and pressure, making it suitable for intake screens, pre-filtration stages, and backwashable filter elements, contributing to cleaner water and protecting more sensitive downstream membrane systems. Our mesh was integrated into a large municipal water treatment plant’s intake system, dramatically reducing the load on subsequent filtration stages and extending the lifespan of their expensive membranes by 25%.

Beyond these major sectors, square weave mesh finds utility in countless other specialized applications. In aerospace, fine mesh acts as EMI/RFI shielding, ventilation screens, and structural components. In plastics and rubber, it's used for melt filtration to ensure product consistency. For automotive, it's found in air filters and exhaust components. Furthermore, the inherent design of square weave mesh offers specific advantages over other filtration media. Unlike some non-woven media that can deform under pressure or certain complex weaves like dutch wire mesh which might offer finer filtration but at a higher pressure drop, square weave mesh maintains its structural integrity and consistent open area under varied operational conditions, providing predictable performance and superior flow characteristics. Its ease of cleaning, particularly for backwashing applications, contributes to lower maintenance costs and longer service intervals. Our commitment to client success extends beyond product delivery; we actively engage in problem-solving. For a client facing consistent clogging issues with their existing filtration system in a pulp and paper mill, our team engineered a specialized 304 stainless steel square weave mesh screen with a larger wire diameter for increased rigidity, which significantly reduced clogging incidents and increased throughput by 20%, illustrating the value of experience and tailored solutions. These diverse applications and real-world results underscore the pivotal role of high-quality square weave mesh in enhancing operational efficiency, product quality, and cost-effectiveness across the industrial spectrum.

Technical Advantages and Performance Superiority of Square Weave Mesh

The technical advantages of square weave mesh are rooted in its fundamental design and meticulous manufacturing, positioning it as a preferred choice over many alternative filtration and screening media for a wide range of industrial applications. One of its foremost strengths is its uniform aperture size and precise opening control. Due to the plain weave pattern with equally spaced warp and weft wires, square weave mesh consistently provides highly accurate and predictable openings. This precision is paramount in applications requiring precise particle sizing, classification, or separation, such as in pharmaceutical powder sieving or chemical catalyst recovery, ensuring product consistency and adherence to strict process specifications. This contrasts with randomly formed media or even certain complex weaves where aperture consistency might vary, leading to less reliable filtration results. Another significant advantage is its high strength-to-weight ratio and mechanical stability. The interwoven structure of square weave mesh creates a robust and dimensionally stable material that can withstand considerable mechanical stress, vibration, and pressure differentials without deforming. This makes it ideal for use as support grids in reactors, reinforcement layers in composite materials, or durable screens in abrasive environments like mining and quarrying, significantly extending the service life of filtration units and reducing replacement frequencies.

Furthermore, square weave mesh exhibits excellent flow characteristics and high open area. The straightforward, unobstructed square openings facilitate maximum fluid or gas flow through the mesh, resulting in minimal pressure drop across the filter medium. This characteristic is crucial for energy efficiency in pump-driven systems and for optimizing throughput in processes such as industrial drying or ventilation. Compared to dense weaves like dutch weave mesh size variants which are designed for finer, often tortuous path filtration with lower open areas, square weave mesh provides a significantly higher open area, making it more suitable for applications requiring high flow rates and efficient solid-liquid or solid-gas separation. Its superior corrosion and temperature resistance is another critical advantage, particularly when manufactured from high-grade stainless steels (304, 316, 316L) or specialized alloys. These materials enable the mesh to operate reliably in highly corrosive chemical environments, at elevated temperatures, or in cryogenic conditions, without material degradation or loss of structural integrity. This ensures long-term performance and reduces the risk of contamination due to material breakdown, a common concern in chemical processing and food industries. The mesh's inherent ease of cleaning and maintenance further contributes to its operational efficiency. Its open structure allows for effective backwashing, rinsing, or mechanical cleaning, facilitating the removal of collected particulates and restoring filtration capacity. This capability extends the service life of the mesh, reduces downtime, and lowers operational costs, unlike some complex filter media that are difficult to clean or require frequent replacement.

Moreover, the abrasion and impact resistance of square weave mesh, particularly when using thicker wires and high-tensile materials, makes it exceptionally durable in applications involving abrasive slurries, high-velocity particle streams, or repetitive mechanical stress. This resilience reduces wear and tear, minimizing costly replacements and operational interruptions. The adaptability for custom fabrication is also a key technical advantage. While standard rolls are common, square weave mesh can be readily cut, formed, welded, and integrated into complex filter elements, screens, baskets, or architectural features. This allows for bespoke solutions that perfectly fit specific equipment designs and operational requirements, offering unmatched flexibility to engineers. While specialized weaves like certain variations of dutch wire mesh might offer extremely fine filtration capabilities, they often come with higher pressure drops and are less suitable for applications requiring high throughput or robust mechanical support. The strength of square weave mesh lies in its balanced performance: a precise and consistent open area, excellent flow characteristics, high mechanical stability, and broad material compatibility, making it a highly reliable and economically advantageous choice for a broad spectrum of industrial filtration, separation, and support applications. These combined technical merits underscore why square weave mesh continues to be a cornerstone material in industries demanding both precision and durability.

Choosing the Right Partner: Vendor Comparison and Customization Solutions for Square Weave Mesh

Selecting the right supplier for square weave mesh is as critical as specifying the product itself, as it directly impacts project timelines, product quality, and long-term operational costs. In a crowded market, discerning the capabilities of various manufacturers requires a thorough evaluation of several key criteria beyond just price. A reputable vendor like Jinjiu Wire Mesh distinguishes itself through a strong emphasis on quality certifications, a comprehensive product range, extensive customization capabilities, robust technical support, and a proven track record of reliable service. Quality certifications are non-negotiable; ISO 9001:2015 accreditation signifies a commitment to consistent quality management systems, from raw material sourcing to final inspection. For specific industries, adherence to standards like ASTM, DIN, or specialized certifications (e.g., FDA compliance for food/pharma grade mesh) is crucial. A transparent manufacturer will readily provide these credentials and detailed material test reports (MTRs) for each batch. Manufacturing capabilities are another differentiator. Leading manufacturers invest in advanced weaving looms, precision cutting equipment, and state-of-the-art inspection tools, ensuring tighter tolerances, uniform mesh apertures, and superior overall product quality. Their capacity to handle both large-volume orders and specialized small-batch productions demonstrates flexibility and responsiveness.

Technical expertise and R&D capabilities are paramount, especially for complex or novel applications. A knowledgeable vendor employs experienced engineers and metallurgists who can provide invaluable technical consultation, assist with material selection, optimize mesh specifications for specific operational parameters (e.g., pressure, temperature, corrosive agents), and troubleshoot existing issues. Jinjiu Wire Mesh, with its decades of experience and dedicated R&D team, consistently works with clients to overcome filtration challenges, offering insights that extend beyond mere product supply. This depth of expertise is particularly valuable when considering alternatives or complementary products, such as various dutch weave mesh size options, where the choice between a simple plain weave and a more complex weave depends entirely on specific application requirements like very fine particle retention or higher pressure filtration. Our extensive service years in the industry are a testament to our enduring commitment to quality and client satisfaction. Customization solutions are a significant area where top-tier suppliers shine. While standard rolls and sheets of square weave mesh meet many needs, industrial applications often require bespoke solutions. This includes custom mesh counts and wire diameters not typically found in standard catalogs, specific material alloys for extreme environments, custom cut-to-size panels, intricate fabricated parts like filter cartridges, baskets, or cylinders, and specialized edge treatments (e.g., welded edges, hemmed edges for safety and rigidity). The ability to provide value-added services like welding, stamping, calendering, and surface finishing (such as electropolishing for sanitary applications) ensures that the supplied square weave mesh perfectly integrates into the client's existing systems, minimizing installation complexities and maximizing performance.

Finally, logistics and after-sales support complete the vendor evaluation. A reliable supplier offers efficient order processing, transparent delivery schedules, and robust packaging to prevent damage during transit. Their global logistics network ensures timely delivery, regardless of geographic location. Post-purchase support, including technical assistance for installation, troubleshooting, and warranty claims, is a hallmark of a customer-centric partner. Jinjiu Wire Mesh prides itself on its responsive customer service and comprehensive after-sales support, ensuring our clients receive continued value long after the purchase. For example, a recent collaboration involved developing a custom filter basket for a client in the wastewater treatment sector. The client initially struggled with off-the-shelf square weave mesh baskets that exhibited premature wear. Our engineering team worked closely with them, suggesting a specific grade of stainless steel with a thicker wire diameter for enhanced durability, along with a custom fabrication that optimized flow and cleaning. This tailored solution not only extended the lifespan of their filter system by over 50% but also significantly improved filtration efficiency, demonstrating the tangible benefits of expert partnership and customized engineering. This level of collaboration and problem-solving is what distinguishes a mere supplier from a strategic partner in the complex B2B landscape, highlighting why choosing Jinjiu Wire Mesh is an investment in unparalleled quality, reliability, and expertise for all your square weave mesh requirements.

Ensuring Trustworthiness: Quality Assurance, Delivery, and Customer Support for Square Weave Mesh

For B2B clients, trustworthiness in a supplier of critical components like square weave mesh is built on a foundation of rigorous quality assurance, transparent delivery logistics, and unwavering customer support. At Jinjiu Wire Mesh, our commitment to these pillars ensures that every product delivered not only meets but often exceeds industry standards and client expectations. Our Quality Assurance (QA) protocol is comprehensive, spanning every stage from raw material procurement to final product dispatch. We initiate quality checks with certified material test reports (MTRs) from our trusted suppliers, verifying the chemical composition and mechanical properties of all incoming wire against stringent international specifications (e.g., ASTM A240 for stainless steel). During the wire drawing process, continuous inline monitoring systems ensure precise diameter control. Automated weaving looms are regularly calibrated and inspected to guarantee consistent mesh count, aperture size, and weave integrity. Post-weaving, each roll or sheet of square weave mesh undergoes meticulous inspection using advanced optical measurement tools and skilled technicians. Key parameters like mesh count, wire diameter, and open area percentage are measured and recorded. Tensile strength tests, burst pressure tests (for fabricated filter elements), and even simulated environmental exposure tests (e.g., salt spray tests for corrosion resistance) are conducted on samples to validate performance under anticipated operating conditions. Our facilities are independently audited and certified to ISO 9001:2015, a testament to our robust quality management system that ensures traceability, consistency, and continuous improvement. This multi-layered inspection regime ensures that every piece of square weave mesh leaving our facility is of the highest quality and ready for demanding industrial applications.

Delivery and Logistics are executed with precision to meet tight industrial schedules. We understand that timely delivery is paramount to avoid costly project delays and production downtimes for our clients. Our sophisticated inventory management system ensures that commonly requested square weave mesh specifications are readily available for immediate dispatch, reducing lead times. For custom or large-volume orders, our sales and production teams provide accurate and transparent lead time estimates, keeping clients informed throughout the manufacturing process. We partner with reputable global logistics providers to ensure secure, efficient, and traceable shipment to any destination worldwide. Each consignment of square weave mesh is expertly packaged to prevent damage during transit, utilizing robust materials and methods tailored to the product's form factor (rolls, sheets, or fabricated components). We offer various shipping options, including sea freight, air freight, and expedited courier services, to accommodate diverse delivery requirements and urgency. Our proactive communication ensures clients receive real-time updates on their order status, from production completion to dispatch and estimated arrival. Customer Support and Warranty Commitments underscore our dedication to client satisfaction. Our experienced technical support team is readily available to assist with product selection, technical inquiries, installation guidance, and troubleshooting. We provide detailed product data sheets, technical specifications, and installation recommendations to ensure optimal performance of our square weave mesh in its intended application. In the rare event of a product defect or performance issue, our responsive after-sales team initiates a thorough investigation, guided by our internal corrective and preventive action (CAPA) procedures, to identify the root cause and implement appropriate solutions swiftly, whether it's a replacement, repair, or technical consultation.

Frequently Asked Questions (FAQ) about Square Weave Mesh

Q1: What is the primary difference between square weave mesh and dutch weave mesh?

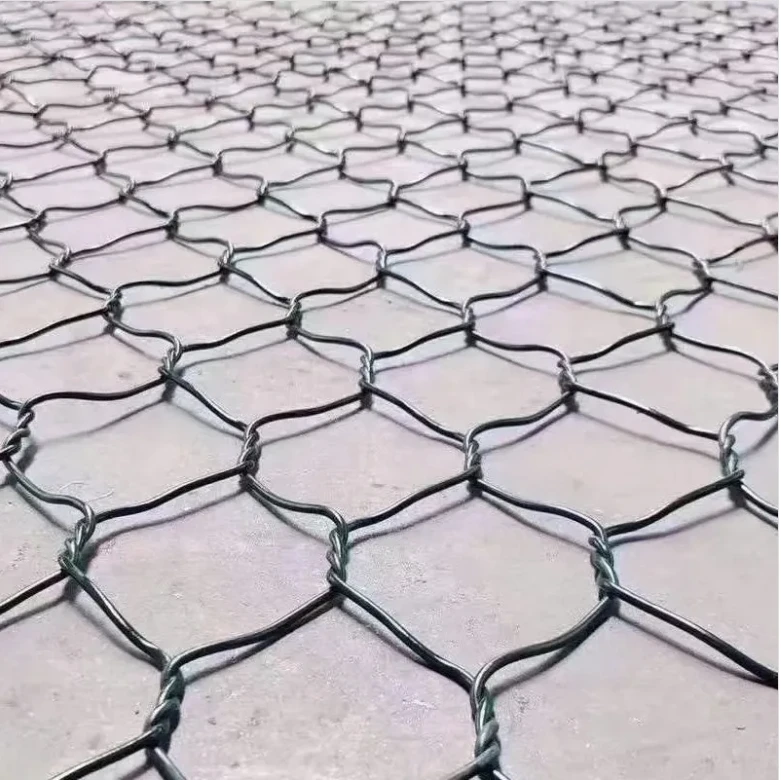

A1: Square weave mesh has equally sized warp and weft wires woven over and under each other, creating precise square openings for accurate particle sizing and high flow. Dutch weave mesh, including dutch wire mesh, uses larger warp wires and smaller, more densely packed weft wires, creating a tortuous path and no visible straight-through openings. This design allows for finer filtration at higher pressures, ideal for applications requiring sub-micron filtration or high-pressure retention, but typically results in lower flow rates compared to square weave mesh.

Q2: How do I select the correct material for my square weave mesh application?

A2: Material selection depends on the operating environment. Stainless steel 304 is common for general use. For corrosive environments (acids, chlorides) or high temperatures, SS 316 or 316L is recommended. Galvanized steel is suitable for outdoor or damp conditions where cost-effectiveness is key, while carbon steel provides strength for dry, non-corrosive applications. For extreme conditions, specialized alloys like Inconel or Hastelloy might be necessary. Consult with our technical team for tailored recommendations.

Q3: What are the typical lead times for custom square weave mesh orders?

A3: Lead times vary based on the complexity of the customization, material availability, and order volume. Standard square weave mesh rolls can often be shipped within a few business days. Custom fabrications or unique mesh specifications may require 2-4 weeks for production. We provide detailed lead time estimates at the time of quotation and keep you updated on progress.

Q4: Can square weave mesh be cleaned and reused, and what is its typical lifespan?

A4: Yes, square weave mesh, particularly stainless steel varieties, is highly durable and can be effectively cleaned using various methods including backwashing, ultrasonic cleaning, or chemical rinsing, making it suitable for prolonged reuse. The lifespan is highly dependent on the operating conditions (abrasion, corrosion, temperature, pressure) and the frequency/effectiveness of cleaning. With proper material selection and maintenance, it can last from several years to over a decade in many industrial applications.

Q5: What certifications does Jinjiu Wire Mesh hold for its products?

A5: Jinjiu Wire Mesh is ISO 9001:2015 certified, ensuring our quality management systems meet international standards. Our products comply with relevant ASTM and DIN specifications. For specific applications like food contact or pharmaceutical use, we can provide material certifications that adhere to FDA or other regulatory requirements, ensuring product safety and traceability. Our long-standing presence and authority in the wire mesh manufacturing industry further attest to our commitment to delivering reliable and high-performance solutions.

The Future Outlook for Square Weave Mesh in Evolving Industries

As global industries continue to evolve, driven by advancements in technology, increasing environmental regulations, and a growing emphasis on operational efficiency, the demand for high-performance filtration and separation solutions, particularly square weave mesh, is set to expand further. The future outlook for square weave mesh is marked by several key trends. Firstly, there will be an increasing focus on advanced materials and alloys. While traditional stainless steel will remain dominant, there's a growing need for mesh capable of withstanding more extreme conditions, such as superalloys for ultra-high temperature filtration in energy production or specialized corrosion-resistant alloys for highly aggressive chemical processes. Research into new material composites and surface treatments will enhance the mesh's performance attributes, including anti-fouling properties, enhanced catalytic support, and superior abrasion resistance. Secondly, sustainability and environmental considerations will drive innovation. Industries are increasingly seeking durable, reusable filtration media to reduce waste and operational footprints. Square weave mesh, with its excellent cleanability and longevity, aligns perfectly with these goals, contributing to circular economy principles by minimizing disposable filter waste. Its role in water purification, air quality control, and efficient resource recovery will become even more critical. Thirdly, precision and miniaturization will be increasingly important. As industries move towards more sophisticated manufacturing processes and require finer control over particle separation, the demand for square weave mesh with even tighter tolerances and smaller, more consistent apertures will grow. This pushes the boundaries of weaving technology and quality control, ensuring that mesh can meet the exacting requirements of microfiltration, nanotechnology, and advanced material processing.

Fourthly, integration with smart systems and automation will transform how square weave mesh is utilized and monitored. The development of sensor-equipped filter elements and real-time monitoring systems will enable predictive maintenance, optimizing cleaning cycles and replacement schedules, thereby maximizing efficiency and minimizing downtime. This intelligent integration will further enhance the value proposition of square weave mesh as a component within interconnected industrial ecosystems. Finally, the growing global population and industrialization in emerging markets will continue to fuel demand for reliable separation technologies in sectors like food processing, pharmaceuticals, and infrastructure development. The fundamental role of square weave mesh in these critical areas ensures its enduring relevance and growth trajectory. While related products like dutch mesh or dutch weave wire mesh will continue to serve their niche applications, the versatility, precision, and robust performance of square weave mesh will cement its position as a cornerstone of industrial filtration and separation. Manufacturers like Jinjiu Wire Mesh are at the forefront of these developments, continuously investing in R&D, advanced manufacturing processes, and comprehensive quality assurance to meet the evolving demands of the global industrial landscape. Our commitment to innovation and customer collaboration ensures that we remain a trusted partner in providing cutting-edge square weave mesh solutions that contribute to cleaner processes, higher productivity, and a more sustainable industrial future.

References and Further Reading

- • ASTM E2016. (2018). Standard Guide for Industrial Woven Wire Cloth. ASTM International. Available at: https://www.astm.org/e2016-18.html

- • ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization. Available at: https://www.iso.org/standard/62085.html

- • Perry, R. H., & Green, D. W. (Eds.). (2008). Perry's Chemical Engineers' Handbook (8th ed.). McGraw-Hill Education. (Discusses filtration media, including woven wire mesh in various industrial contexts).

- • Rushton, A., Ward, A. S., & Holdich, R. G. (2007). Solid-Liquid Filtration and Separation Technology (2nd ed.). Wiley-VCH. (Provides in-depth analysis of filtration mechanisms and media).

Related Products

Related News