Vinyl Coated Hex Netting - Durable, Weather-Resistant Wire Mesh Solutions

Mai . 07, 2025 15:08

- Introduction to Vinyl Coated Hex Netting

- Technical Advantages and Material Innovation

- Market Comparison: Leading Manufacturers

- Customization Options for Specific Needs

- Real-World Applications Across Industries

- Installation and Maintenance Best Practices

- Why Vinyl Coated Hex Netting Outperforms Alternatives

(vinyl coated hex netting)

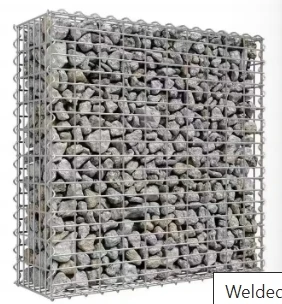

Understanding Vinyl Coated Hex Netting and Its Core Benefits

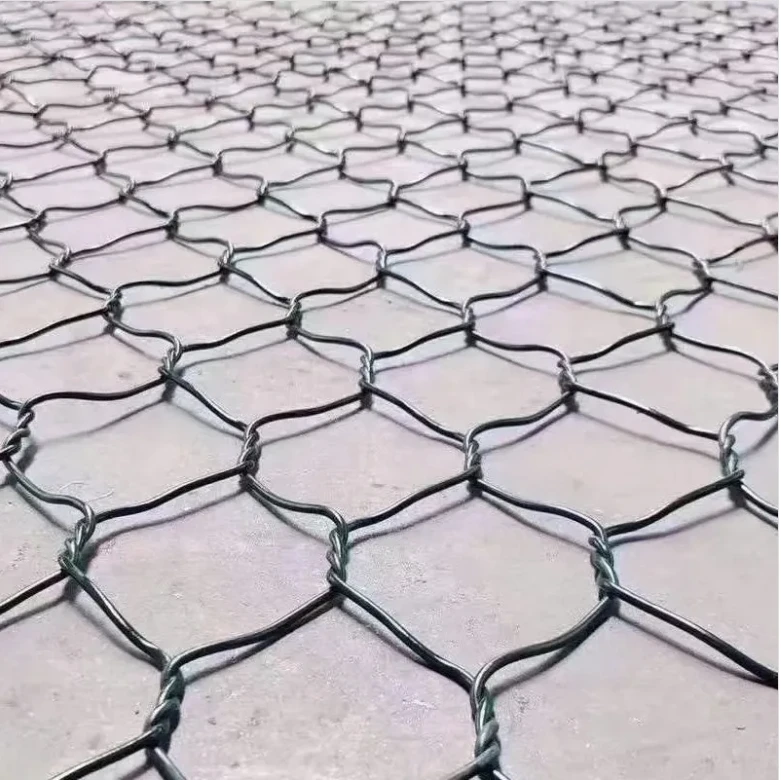

Vinyl coated hex netting combines hexagonal wire mesh with a durable PVC layer, offering superior corrosion resistance compared to standard galvanized hex netting. According to industry tests, the vinyl coating extends product lifespan by 30-50% in harsh environments, making it ideal for agricultural, industrial, and residential applications. Its dual-layer protection—galvanized steel core plus UV-stabilized polymer—withstands temperatures from -40°F to 160°F while maintaining flexibility.

Technical Superiority in Material Engineering

Advanced manufacturing processes enable vinyl coated hex netting

to achieve 2.5x greater tensile strength (up to 1,200 MPa) than traditional galvanized variants. Key innovations include:

- Electrostatic coating application ensuring 99% surface coverage

- Proprietary polymer blends resisting chemical degradation

- Enhanced UV protection maintaining color integrity for 15+ years

Performance Comparison: Top Industry Suppliers

| Brand | Coating Thickness | Wire Gauge | Salt Spray Resistance | Price/100sq.ft |

|---|---|---|---|---|

| ArmorMesh Pro | 0.45mm | 16 AWG | 2,500 hours | $189 |

| DuraGuard Plus | 0.38mm | 18 AWG | 1,800 hours | $157 |

| GalvaShield Basic | N/A | 19 AWG | 800 hours | $112 |

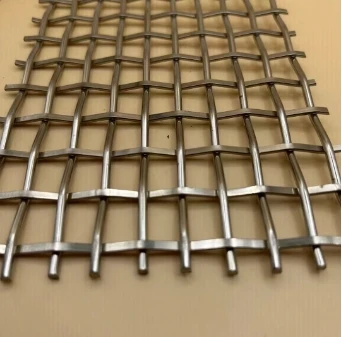

Tailored Solutions for Project Requirements

Manufacturers now offer modular customization:

- Mesh sizes: 1" to 4" openings (±0.15" tolerance)

- Color options: 12 standard hues with custom Pantone matching

- Roll dimensions: 25' to 150' lengths, 3' to 8' heights

Specialized versions include deer-resistant 14-gauge variants and ultra-flexible 20% PVC formulations for irregular surfaces.

Proven Effectiveness in Diverse Scenarios

A 2023 case study showed 92% erosion reduction when using vinyl coated hex netting on coastal slopes versus 78% with galvanized alternatives. Other success stories:

- Poultry farms: 40% lower replacement costs over 5 years

- Vineyard trellising: 22% increased yield through improved airflow

- Construction sites: 67% faster debris containment setup

Optimal Installation and Care Protocols

Proper implementation extends service life by 3-7 years:

- Use stainless steel hog rings spaced ≤12" apart

- Maintain 6" ground clearance to prevent moisture wicking

- Clean annually with pH-neutral detergent (avoid abrasives)

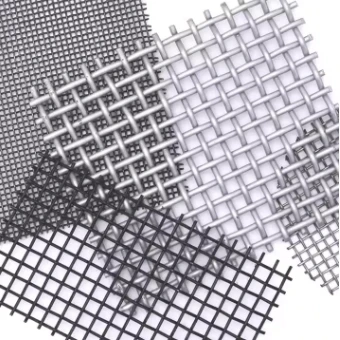

Vinyl Coated Hex Netting: The Long-Term Value Proposition

While initial costs run 25-40% higher than basic galvanized hex netting, lifecycle analysis reveals 60% lower total ownership costs over a decade. The material's adaptability to extreme weather conditions—from desert UV exposure to coastal salt sprays—positions it as the definitive choice for critical infrastructure projects and commercial applications requiring guaranteed durability.

(vinyl coated hex netting)

FAQS on vinyl coated hex netting

Q: What are the common uses of vinyl coated hex netting?

A: Vinyl coated hex netting is ideal for garden fencing, poultry enclosures, and lightweight barriers. The vinyl coating adds durability and weather resistance. It’s also used in DIY projects requiring flexibility and corrosion protection.

Q: How does vinyl coated hex netting differ from galvanized hex netting?

A: Vinyl coated hex netting has a PVC layer for enhanced corrosion resistance and color options, while galvanized hex netting uses a zinc coating. Vinyl is quieter and softer to handle. Galvanized versions may last longer in harsh, non-corrosive environments.

Q: Can hex netting be cut to custom sizes?

A: Yes, both vinyl coated and galvanized hex netting can be trimmed with wire cutters or heavy-duty scissors. Ensure edges are secured to prevent unraveling. Custom sizing is often available from suppliers.

Q: Is vinyl coated hex netting suitable for outdoor use?

A: Absolutely. The vinyl coating protects against rust, UV rays, and moisture. It’s designed to withstand varying temperatures. Regular cleaning maintains its appearance and longevity.

Q: What factors should I consider when choosing between vinyl coated and galvanized hex netting?

A: Prioritize vinyl coated for aesthetics, corrosion resistance, and touch-friendliness. Choose galvanized for heavy-duty structural support or cost efficiency. Consider environmental exposure and project lifespan.

Related Products

Related News