FAQS

Welded Wire Mesh Panel FAQ

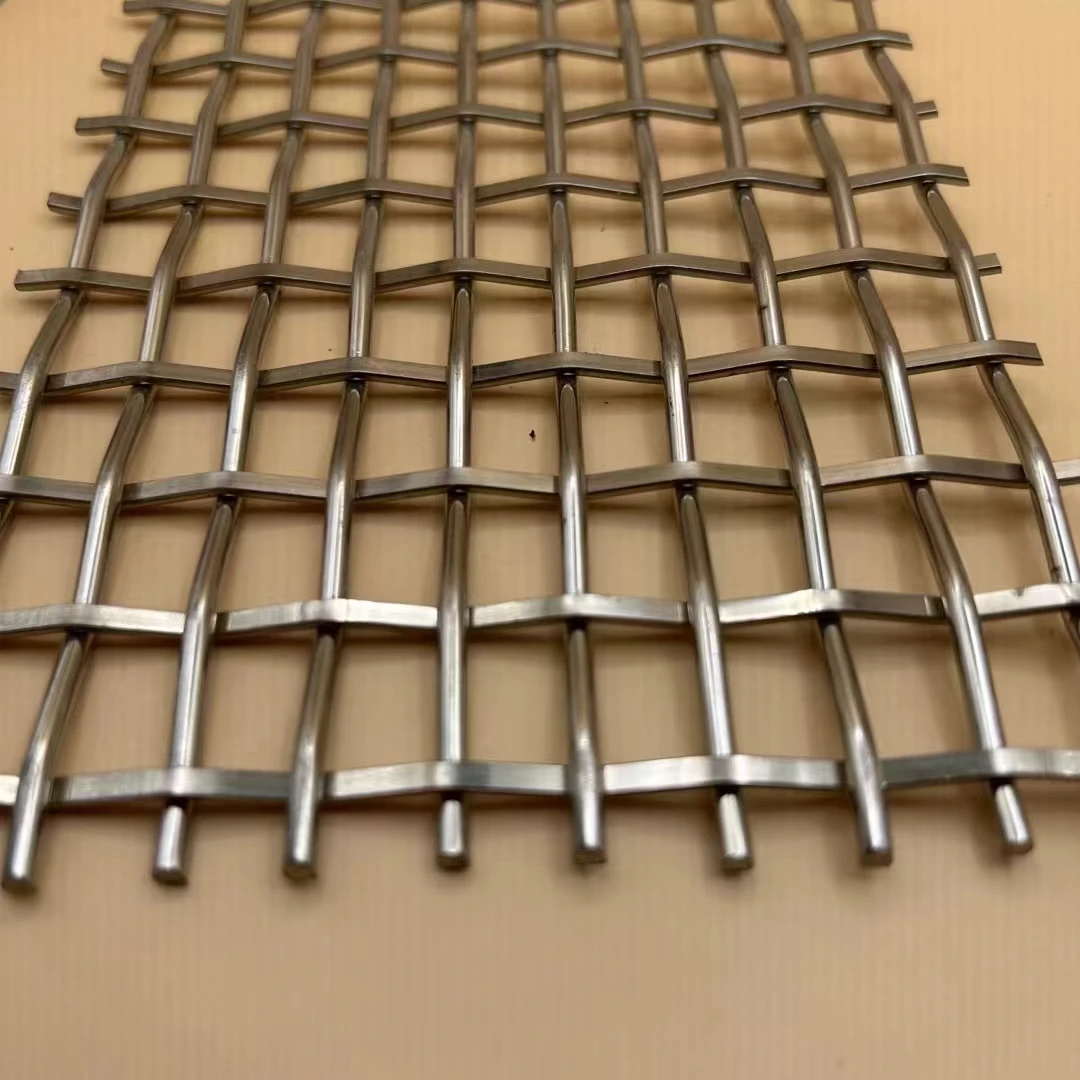

What is welded wire mesh panel and what is the difference between it and welded steel wire mesh?

Welded wire mesh panel is a flat plate made of intersecting steel wires welded together at their joints, usually made of steel or other durable materials. Compared with welded steel wire mesh, it is a flat structure, while welded steel wire mesh focuses more on mesh fence materials, which are different in shape and some uses.

What are the common uses of welded wire panels?

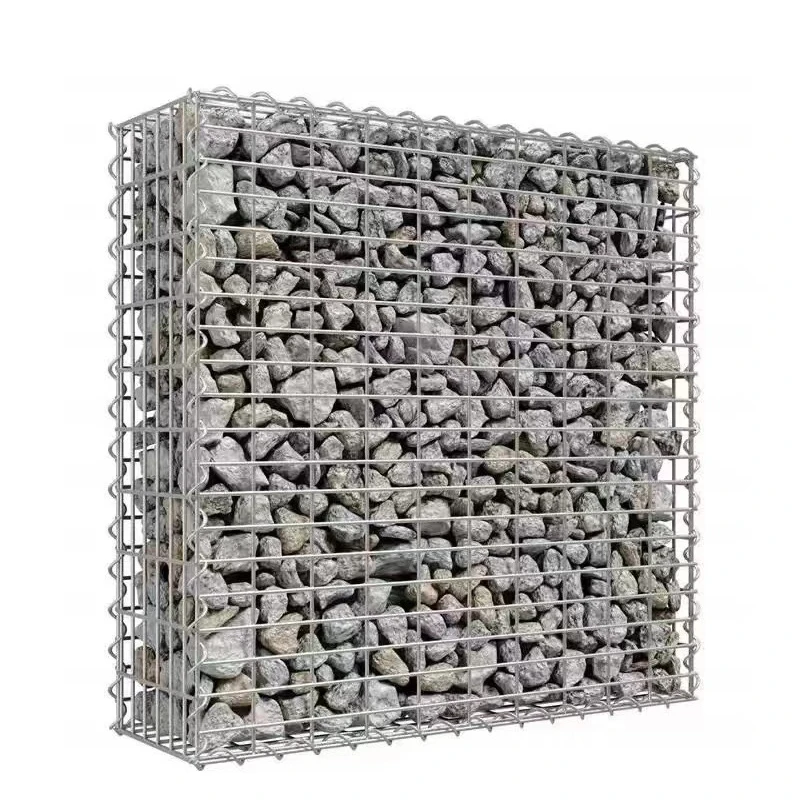

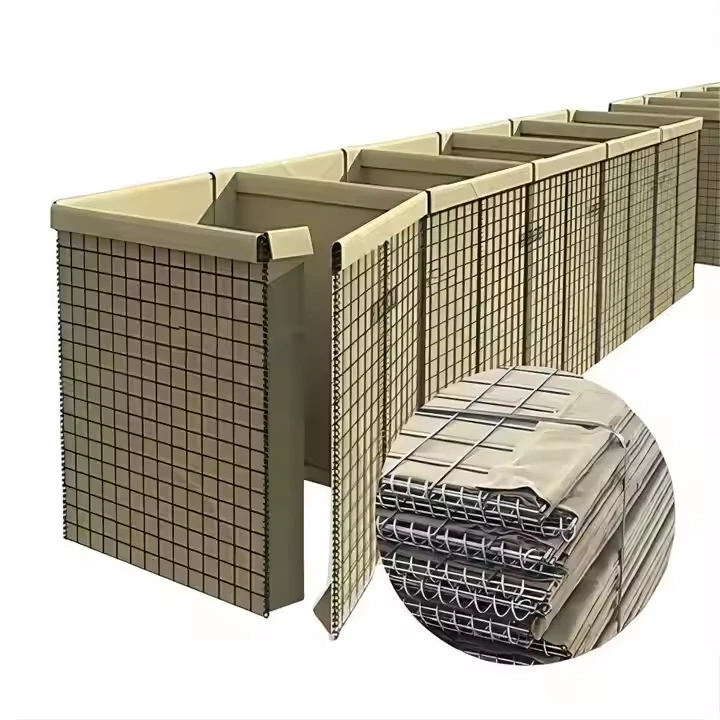

Welded wire panel is often used in fences to provide security and boundary division for residential, commercial and agricultural real estate; Used to reinforce concrete structures, such as slabs, walls and pavements; Used in animal pens to create a safe habitat for livestock and pets; It is also used in industrial applications, such as as safety barriers, shelves and storage solutions for warehouses and factories.

What is the application of welded mesh panel in the world?

In the United States, welded wire mesh panels are widely used in residential and commercial fences and building projects to increase structural support; In Europe, Germany and France, it is used for agricultural fences and industrial applications; In Asia, India and China and other countries, because of its cost-effectiveness and versatility, welded wire mesh panels are used in construction, agriculture and even landscaping; In Australia and New Zealand, it is favored because it can provide safety fences for livestock and gardens.

If the project has requirements for fire prevention, how to choose welded wire fencing panel?

Preference is given to welded wire mesh panels made of materials with good fire resistance, such as some specially treated steels. At the same time, check the product's fire rating certification to ensure that it meets the fire protection standards of the project. If necessary, you can also consult professionals or suppliers to find out whether there is a special coating or treatment process for fire protection requirements.

Related Products

Related News

We can customized wire mesh products

by your drawing and requirements