FAQS

Steel Wire Rope FAQ

How are steel wire ropes classified?

Steel wire ropes are mainly classified according to the structure and the type of steel used. Structurally, there are 6x19, 6x37, 8x19 configurations, and the numbers represent the number of shares and steel wires per share; Materials are classified into carbon steel, stainless steel and alloy steel; There are also coating options, such as zinc plating and plastic coating, and different categories correspond to different performance characteristics.

What are the specifications of steel wire rope?

The structure of steel wire rope is 1x19, 6x7, 6x19, etc. The diameter ranges from 4 mm to 70 mm; Twist directions include right twist, left twist, right alternate twist and left alternate twist; The coating includes zinc plating, stainless steel, polyvinyl chloride or grease coating; The tensile strength is 1570/1670/1770/1870/1960/2160 Newton/MM²

What's the difference in performance of steel wire ropes with different structures?

6x19 structural steel wire rope is relatively hard and has good wear resistance, which is often used in scenes with high strength requirements and great wear. The steel wire rope with 6x37 structure is softer and more flexible, which is suitable for occasions that need frequent bending, such as the hoisting rope of a crane. The selection should be based on the requirements of specific application scenarios for strength, flexibility and wear resistance.

How to choose the appropriate steel wire rope according to the use environment?

In general environment such as construction site, carbon steel wire rope can meet the demand with high tensile strength; The marine environment is highly corrosive, so it is necessary to choose stainless steel wire rope with good corrosion resistance; In the industrial manufacturing environment with chemical corrosion risk, steel wire rope coated with protective coating, such as galvanized or PVC coated steel wire rope, can be considered.

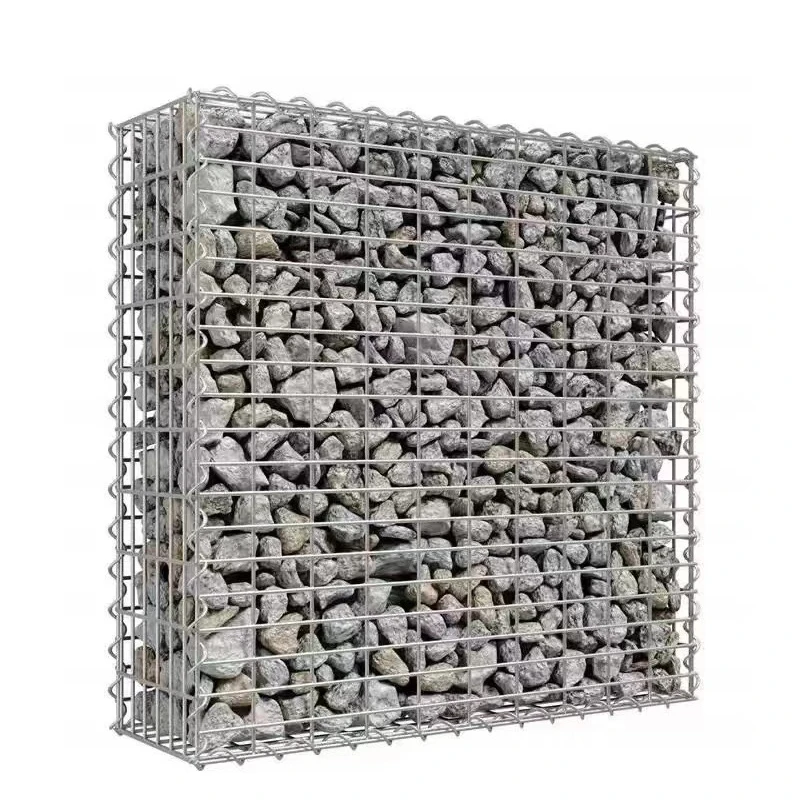

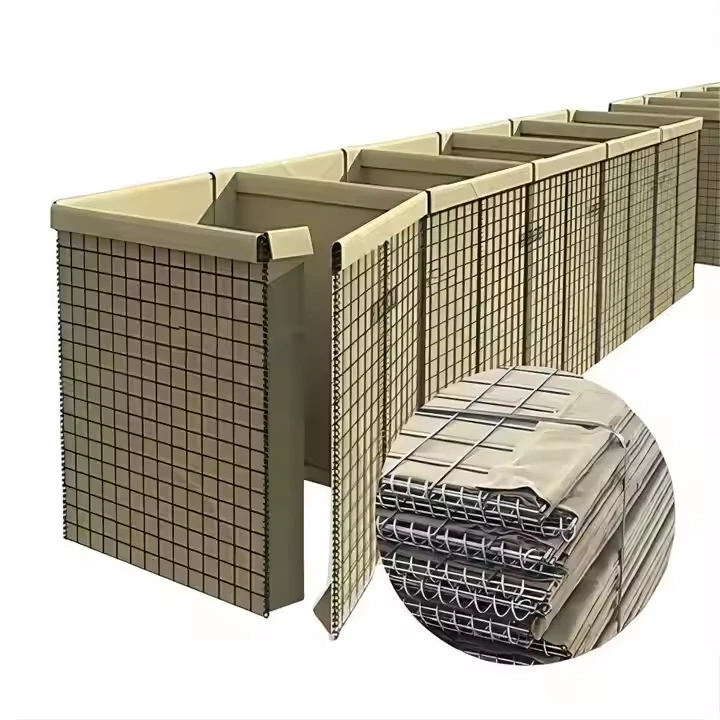

Related Products

Related News

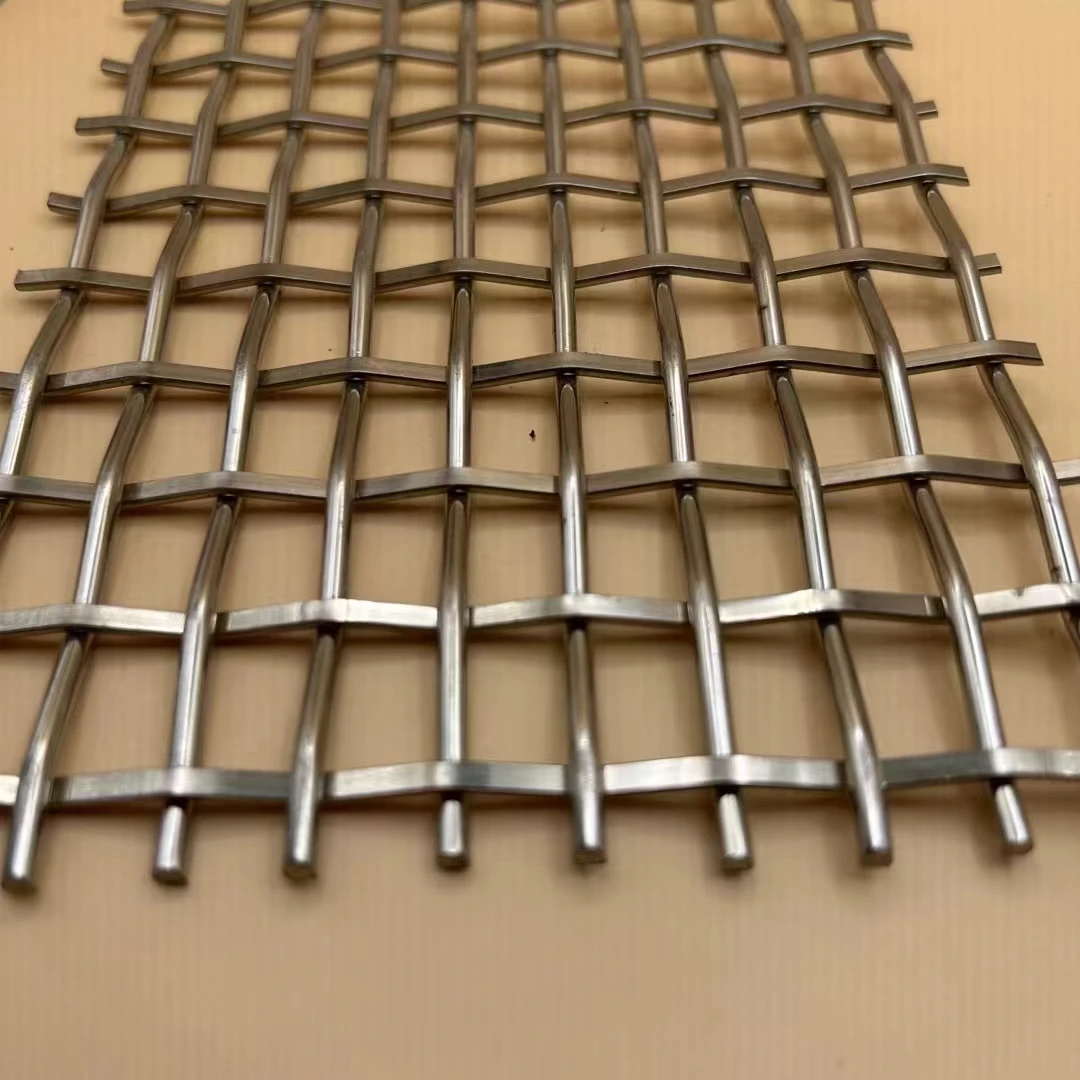

We can customized wire mesh products

by your drawing and requirements