Secure Australia Temporary Fence for Sites & Events

aug . 09, 2025 05:40

The burgeoning development across the continent, from sprawling urban construction projects to vibrant public events and stringent safety regulations, has significantly amplified the demand for robust and reliable temporary fencing solutions. At the forefront of this essential industry is the australia temporary fence, a critical component in ensuring site safety, crowd control, and asset protection. This comprehensive guide delves deep into the world of Australian temporary fencing, exploring its critical role, technical intricacies, manufacturing excellence, diverse applications, and the factors that establish trustworthiness in a highly competitive market.

Industry Trends and the Growing Demand for Temporary Fencing in Australia

Australia's economic landscape is characterized by dynamic growth in key sectors, directly influencing the need for effective temporary containment. The construction industry, a significant contributor to the nation's GDP, consistently sees new residential, commercial, and infrastructure developments. Each of these projects mandates secure perimeters to protect workers, the public, and valuable equipment. Furthermore, Australia's vibrant cultural scene hosts countless festivals, sporting events, and public gatherings, all requiring efficient crowd management and designated zones, often achieved through the deployment of high-quality australia temporary fencing.

Beyond construction and events, regulatory frameworks, particularly concerning public safety and pool fencing, drive specific demands. For instance, the AS 1926.1-2012 standard for swimming pool safety dictates strict requirements for barriers, making temporary pool fencing a non-negotiable for pool construction or renovation sites. This regulatory push, combined with an increasing awareness of workplace safety and public liability, underscores a sustained and escalating demand for versatile, compliant, and durable temp fence australia solutions. According to a market analysis report, the temporary fencing market in Oceania is projected to grow at a Compound Annual Growth Rate (CAGR) of approximately 5.5% from 2023 to 2028, largely driven by the robust construction pipeline and a busy events calendar across Australia and New Zealand.

The emphasis on reusability and environmental responsibility also shapes current trends. Companies increasingly seek fencing solutions that can be easily installed, dismantled, transported, and reused across multiple projects, minimizing waste and maximizing return on investment. This shift favors products like the australia temporary fence which are designed for durability and longevity, capable of withstanding Australia's diverse climatic conditions, from harsh sunlight to strong winds.

Understanding Australia Temporary Fence: Technical Parameters & Specifications

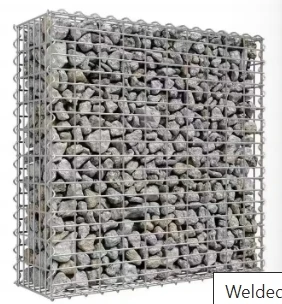

The effectiveness of an australia temporary fence hinges on its precise technical specifications and robust construction. Typically, these systems consist of a fence panel, supporting feet (bases), and clamps. Understanding the key parameters is crucial for selecting the right product for a given application.

Core Components and Materials:

- Fence Panels: These are usually constructed from high-quality low-carbon steel wire, which is then welded into a mesh pattern. The most common mesh configurations are 60x150mm, 75x150mm, or 100x200mm openings, offering a balance between visibility and security. The wire diameter typically ranges from 3.0mm to 5.0mm, with heavier gauges indicating greater strength and durability.

- Frame Pipes: The mesh panels are framed by sturdy steel pipes, providing structural integrity. Common pipe diameters for the vertical and horizontal frames are 32mm OD (Outer Diameter), 40mm OD, or 42mm OD, with wall thicknesses ranging from 1.5mm to 2.5mm. Square pipes (e.g., 25x25mm) are also used in some designs.

- Surface Treatment: The primary method for corrosion resistance is hot-dip galvanization, conforming to Australian standards like AS/NZS 4680:2006 for hot-dip galvanized (zinc) coatings on fabricated ferrous articles. This process provides a thick, uniform zinc coating that protects the steel from rust and extends the fence's lifespan significantly, crucial for outdoor applications. A typical galvanization thickness might be 42 microns or higher, ensuring longevity even in harsh coastal environments.

- Fence Feet (Bases): Often made from high-density polyethylene (HDPE) or concrete, these bases provide stability to the fence panels. HDPE feet are popular due to their light weight, reusability, and ability to be stacked, facilitating transport and storage. Concrete bases offer superior stability in high-wind areas.

- Clamps: Steel clamps are used to connect adjacent fence panels, ensuring a continuous and secure barrier. These are also typically hot-dip galvanized for durability.

Standard Dimensions:

While custom sizes are available, standard panel dimensions for australia temporary fence are:

- Height: 1.8 meters (approx. 6 feet), 2.1 meters (approx. 7 feet), 2.4 meters (approx. 8 feet)

- Width: 2.1 meters, 2.4 meters, 2.9 meters (for specific applications like event fencing)

Table: Typical Australia Temporary Fence Specifications Comparison

To further illustrate the variations, here's a comparison of common specifications:

| Parameter | Standard Construction Grade | Heavy-Duty Event Grade | Pool Fencing Grade (AS 1926.1-2012 Compliant) |

|---|---|---|---|

| Panel Height | 1.8m - 2.1m | 2.1m - 2.4m | 1.2m (minimum for pool fencing) |

| Panel Width | 2.4m | 2.9m (often) | 2.4m |

| Wire Diameter | 3.0mm - 3.5mm | 4.0mm - 5.0mm | 3.0mm - 4.0mm |

| Mesh Opening | 60x150mm, 75x150mm | 60x150mm, 75x150mm | Less than 100mm (vertical), less than 10mm (horizontal gaps under 900mm height) |

| Frame Pipe OD | 32mm, 40mm | 42mm, 48mm | 32mm, 40mm |

| Frame Pipe Wall Thickness | 1.5mm - 1.8mm | 2.0mm - 2.5mm | 1.5mm - 1.8mm |

| Surface Treatment | Hot-dip Galvanized (42 microns+) | Hot-dip Galvanized (60 microns+) | Hot-dip Galvanized (42 microns+) |

| Fence Feet Type | HDPE, Concrete | Heavy-duty HDPE, Concrete | HDPE, Concrete (Stable & non-climbable) |

| Applicable Standard | AS 4687-2007 | AS 4687-2007 (Enhanced) | AS 1926.1-2012 |

| Typical Lifespan | 5-10 years | 10-15+ years | 5-10 years |

This table highlights how variations in specifications cater to different demands, from standard site security to high-impact events or critical safety applications like temporary pool fencing australia.

The Manufacturing Process of Australia Temporary Fence

The manufacturing of a high-quality australia temporary fence involves a meticulous process, ensuring durability, strength, and compliance with industry standards. Jinjiu Wire Mesh employs advanced techniques and stringent quality control at each stage, from raw material selection to the final galvanized product.

Detailed Process Flow:

-

Raw Material Procurement (Steel Wire & Pipes):

The process begins with sourcing high-grade low-carbon steel wire (Q195/Q235) and steel pipes (round or square). The chemical composition and mechanical properties of these raw materials are rigorously tested to ensure they meet internal quality benchmarks and relevant international standards such as ASTM A82/A185 for steel wire and ASTM A500 for structural tubing. This initial quality check is crucial as it forms the foundation of the product's integrity.

(Diagram/Image Placeholder: Illustration showing raw steel coils and pipes being inspected upon arrival, with arrows pointing to chemical analysis and tensile testing.)

-

Wire Straightening and Cutting:

The steel wire coils are fed into an automatic wire straightening and cutting machine. This machine precisely straightens the wire and cuts it into specific lengths required for the mesh panel's vertical and horizontal wires. Accuracy at this stage is vital for the uniform appearance and structural integrity of the final mesh.

(Diagram/Image Placeholder: Automated machine feeding wire, cutting, and stacking straightened pieces.)

-

Mesh Welding:

The straightened and cut wires are then fed into an advanced automatic mesh welding machine. This machine precisely positions the wires and uses resistance welding technology to fuse them at each intersection point. The welding parameters (current, pressure, time) are carefully controlled to ensure strong, consistent welds that prevent mesh deformation and enhance the panel's overall strength. This critical step forms the core of the temporary fence australia panel.

(Diagram/Image Placeholder: Grid of wires being welded by automated electrodes, showing sparks at welding points with an arrow indicating "Strong Welds".)

-

Frame Fabrication (Bending & Welding):

The steel pipes for the frame are cut to length, and if necessary, specific sections are bent using hydraulic pipe bending machines to form the top, bottom, and side frames. These frame components are then welded together using MIG (Metal Inert Gas) welding or resistance welding. Skilled welders ensure all joints are strong, clean, and free from defects, forming a robust perimeter for the mesh panel.

(Diagram/Image Placeholder: Pipes being cut and bent, then a worker welding frame sections together.)

-

Panel Assembly (Mesh Insertion & Welding to Frame):

The welded mesh panels are inserted into the fabricated frames. The mesh is then spot-welded or continuous-welded to the inside of the frame pipes. This connection is critical for ensuring the mesh remains taut and secure within the frame, preventing tampering and increasing the panel's durability against impacts or environmental stresses. For aus temp fencing, this assembly ensures the entire structure functions as a cohesive barrier.

(Diagram/Image Placeholder: Mesh panel being placed into a frame, with welding points indicated.)

-

Hot-Dip Galvanization:

After assembly, the entire fence panel undergoes hot-dip galvanization. This multi-step process includes:

- Degreasing: Removing oil, grease, and dirt from the steel surface.

- Pickling: Immersion in an acid solution (hydrochloric acid) to remove rust and mill scale.

- Rinsing: Washing off residual acid.

- Fluxing: Immersion in a zinc ammonium chloride solution to prepare the steel surface for bonding with zinc.

- Galvanizing: Dipping the panels into a molten zinc bath (typically at 450-460°C). The zinc metallurgically bonds with the steel, forming multiple layers of zinc-iron alloy and an outer layer of pure zinc. This provides superior corrosion protection compared to other coating methods. The galvanization thickness is carefully monitored to meet AS/NZS 4680:2006 standards (minimum average coating mass of 42 microns for fabricated articles).

- Cooling & Inspection: Panels are slowly cooled and then visually inspected for complete coverage, smooth finish, and absence of defects. Adhesion and thickness tests are also conducted using non-destructive methods (e.g., magnetic induction thickness gauge).

(Diagram/Image Placeholder: Series of vats representing the galvanization process steps: Degreasing → Pickling → Rinsing → Fluxing → Zinc Bath → Cooling, with arrows indicating flow and text highlighting "Hot-Dip Galvanization: Superior Corrosion Protection".)

-

Quality Control & Final Inspection:

Throughout the manufacturing process, and especially after galvanization, strict quality control measures are implemented. This includes dimensional checks (height, width, mesh size, wire/pipe diameters), weld integrity tests, and galvanization thickness and adhesion tests (e.g., adherence test according to ISO 1461). Panels are also checked for flatness and overall structural integrity. The products must comply with AS 4687-2007 (Temporary Fencing and Hoardings) for general temporary fencing, and AS 1926.1-2012 for temporary pool fencing australia.

(Diagram/Image Placeholder: QC personnel with measuring tools inspecting a finished fence panel, checking dimensions and coating quality.)

-

Packaging & Shipping:

Finished australia temporary fence panels are bundled and securely packaged, often with protective wrapping, to prevent damage during transport. Bases and clamps are also packaged separately. Products are then ready for dispatch to construction sites, event organizers, or distributors across Australia.

(Diagram/Image Placeholder: Stacked fence panels, wrapped and ready for loading onto a truck.)

This comprehensive manufacturing process, with its emphasis on quality materials, precision fabrication, and hot-dip galvanization, ensures that Jinjiu Wire Mesh's australia temporary fence products offer exceptional durability, a long service life (typically 5-15 years depending on maintenance and environmental exposure), and robust performance across a variety of demanding applications. The adherence to international and Australian standards like ISO 9001 for quality management systems further underscores the commitment to excellence. While traditional manufacturing methods like casting, forging, or CNC machining are not typically used for temporary fencing (which relies on welding and bending of steel), the detailed process above highlights the specialized fabrication and surface treatment techniques critical to this product category.

Application Scenarios and Technical Advantages

The versatility of australia temporary fence makes it an indispensable solution across a multitude of sectors, each benefiting from its unique technical advantages.

Primary Application Scenarios:

- Construction Sites: This is arguably the most common application. Australia temporary fencing is used to delineate construction zones, restrict unauthorized access, protect public safety from hazards like falling debris or machinery, and secure equipment. Its ease of installation and relocation makes it ideal for dynamic construction environments where site boundaries change as work progresses.

- Event Management: From music festivals and sporting events to outdoor markets and public gatherings, temp fence australia is crucial for crowd control, directing pedestrian flow, creating secure VIP areas, and preventing gatecrashing. The robust nature of heavy-duty event-grade fencing ensures it can withstand large crowds and repeated use.

- Public Safety and Roadworks: When roads are under maintenance, or public areas require temporary closure due to hazards, temporary fence australia provides clear physical barriers. This helps guide traffic, protect workers, and warn the public of potential dangers. Its high visibility, often enhanced with safety mesh or reflective tape, is a key advantage.

- Temporary Pool Fencing: Adhering to strict Australian regulations (AS 1926.1-2012), specialized temporary pool fencing australia is mandatory during the construction or renovation of swimming pools. These fences are designed to be non-climbable, with specific mesh sizes and height requirements to prevent unsupervised access by young children, thereby preventing drowning incidents. This application highlights the product's role in critical safety compliance.

- Demolition Sites: Similar to construction, demolition sites require stringent security to control access and contain dust or debris. Temporary fencing provides an effective perimeter during these operations.

- Animal Containment: In rural or agricultural settings, temporary fencing can be used for short-term animal enclosures or to manage livestock movement.

Technical Advantages of Australia Temporary Fence:

- Rapid Deployment and Mobility: One of the most significant advantages is the speed and ease with which these fences can be installed and dismantled. Unlike permanent fencing, temporary systems require no digging or complex foundations, making them ideal for projects with evolving needs or short durations. A small crew can install hundreds of meters in a single day.

- High Reusability and Cost-Effectiveness: Constructed from durable galvanized steel, these fences are built to withstand repeated use across multiple projects. Their modular design allows for easy transport and storage, significantly reducing long-term costs compared to disposable or less robust alternatives. This also aligns with sustainable practices by minimizing material waste.

- Superior Durability and Weather Resistance: The hot-dip galvanization process provides exceptional protection against rust and corrosion, enabling the fences to endure Australia's harsh weather conditions, including intense UV radiation, heavy rains, and saline coastal environments. This ensures a long service life and consistent performance without significant degradation.

- Enhanced Security and Safety Compliance: The robust welded mesh and sturdy frame provide a significant deterrent to unauthorized entry. When deployed correctly, aus temp fencing systems meet or exceed national safety standards like AS 4687-2007 for temporary fencing and AS 1926.1-2012 for pool barriers, thereby reducing liability risks and ensuring the safety of workers and the public.

- Flexibility and Adaptability: The modular nature allows for easy configuration into various shapes and lengths, adapting to irregular site boundaries, sloped terrain, or specific access requirements. Gates can be seamlessly integrated for controlled entry and exit.

- Low Maintenance: Due to their galvanized finish, these fences require minimal maintenance, primarily just occasional cleaning. This contributes to their low total cost of ownership.

In essence, the technical advantages of australia temporary fencing directly translate into operational efficiencies, enhanced safety, and greater economic value for businesses and organizations across Australia.

Manufacturer Comparison and Choosing the Right Supplier

When selecting a supplier for your australia temporary fence needs, the market offers various options, but not all manufacturers are created equal. The choice of supplier directly impacts the quality, compliance, and longevity of your fencing solution. Jinjiu Wire Mesh distinguishes itself through a steadfast commitment to quality, adherence to Australian standards, and comprehensive customer support.

Key Factors to Consider When Comparing Manufacturers:

-

Material Quality and Specifications:

- Jinjiu Wire Mesh: Utilizes high-grade Q195/Q235 low-carbon steel for mesh and robust steel pipes for frames. Adheres strictly to specified wire diameters (e.g., 3.0mm to 5.0mm) and pipe wall thicknesses (e.g., 1.5mm to 2.5mm), ensuring structural integrity and longevity.

- Generic/Lower-Tier Suppliers: May use lower-grade steel, thinner wire gauges, or thinner pipe wall thicknesses, compromising strength and durability, leading to premature bending or breakage.

-

Manufacturing Process and Welding Strength:

- Jinjiu Wire Mesh: Employs advanced automatic mesh welding machines and skilled welders for frame fabrication. Strict quality control on welding parameters ensures strong, consistent, and clean welds at every joint, crucial for the panel's resilience.

- Generic/Lower-Tier Suppliers: Manual welding or less precise automated processes can result in weak, inconsistent, or visually poor welds, making the fence susceptible to failure under stress.

-

Galvanization Quality and Adherence to Standards:

- Jinjiu Wire Mesh: Specializes in hot-dip galvanization, strictly adhering to AS/NZS 4680:2006. Ensures a minimum average zinc coating thickness of 42 microns (often higher for heavy-duty grades), providing superior corrosion resistance for decades.

- Generic/Lower-Tier Suppliers: May use electro-galvanization (thinner coating, less durable) or provide inadequate hot-dip galvanization thickness (e.g., 20-30 microns), leading to rapid rust formation, especially in coastal or high-humidity environments.

-

Compliance with Australian Standards:

- Jinjiu Wire Mesh: All temporary fencing products are designed and manufactured to comply with AS 4687-2007 for temporary fencing and hoardings, and specifically AS 1926.1-2012 for temporary pool fencing australia. This ensures products meet the rigorous safety and performance requirements mandated in Australia.

- Generic/Lower-Tier Suppliers: May offer products that do not fully comply with relevant Australian standards, posing significant safety risks and potential legal liabilities for users.

-

Reputation and Experience:

- Jinjiu Wire Mesh: With over two decades of experience in wire mesh manufacturing, Jinjiu Wire Mesh has established itself as a trusted name, serving a global clientele, including significant markets in Australia. Our long service history and extensive portfolio of successful projects speak volumes about our reliability and expertise.

- Generic/Lower-Tier Suppliers: Newer or less established suppliers may lack the proven track record, quality assurance protocols, or financial stability to consistently deliver high-quality products and support.

-

Customization Capabilities:

- Jinjiu Wire Mesh: Offers comprehensive customization options including specific panel heights and widths, varied mesh configurations, gate integration, and specialized foot designs to meet unique project requirements.

- Generic/Lower-Tier Suppliers: Often limited to standard stock sizes, which may not perfectly fit specialized project needs.

-

After-Sales Support and Warranty:

- Jinjiu Wire Mesh: Provides robust after-sales support, including guidance on installation, maintenance, and a clear warranty policy, ensuring customer satisfaction and long-term product performance.

- Generic/Lower-Tier Suppliers: May offer limited or no after-sales support, leaving customers without assistance for issues or concerns post-purchase.

By prioritizing these factors, customers can make an informed decision, ensuring they invest in a temp fence australia solution that is not only cost-effective but also safe, compliant, and durable. Jinjiu Wire Mesh's unwavering commitment to these principles positions it as a leading choice for all temporary fencing requirements in Australia.

Customized Solutions for Diverse Needs

While standard dimensions for australia temporary fence panels cater to many applications, unique project requirements often demand tailored solutions. Jinjiu Wire Mesh excels in providing comprehensive customization options, ensuring that clients receive fencing systems perfectly adapted to their specific site conditions, safety protocols, and aesthetic preferences.

Types of Customization Available:

-

Dimensions (Height & Width):

Projects may require non-standard fence heights for increased security (e.g., 2.4m for high-security areas) or reduced visibility (e.g., 1.5m for low-impact events). Similarly, custom panel widths can optimize coverage for specific site layouts, reducing the number of panels required or fitting into constrained spaces. This flexibility is crucial for efficient site management.

-

Mesh Configuration & Wire Gauge:

Depending on the required level of security and visibility, customers can specify variations in mesh opening sizes (e.g., smaller apertures for enhanced anti-climb properties) and wire diameters. For example, a heavy-duty australia temporary fencing solution might use 5.0mm wire for maximum robustness, while a standard construction fence might use 3.2mm wire for a balance of strength and cost.

-

Frame Pipe Specifications:

The diameter and wall thickness of the frame pipes can be customized to enhance the structural integrity for particularly demanding environments (e.g., high wind zones) or heavy usage. Larger diameter pipes (e.g., 48mm OD) and thicker walls (e.g., 2.5mm) provide superior rigidity and resistance to impact.

-

Gate Integration:

Custom gates (pedestrian gates, vehicle gates, sliding gates) can be fabricated to seamlessly integrate with the temporary fence system. These gates can be designed with specific locking mechanisms, widths, and heights to accommodate different access requirements, ensuring controlled entry and exit points for workers, vehicles, or equipment.

-

Specialized Feet/Bases:

While standard HDPE or concrete feet are common, customized bases can be provided. This includes extra-heavy bases for high-wind areas, specialized feet for uneven terrain, or low-profile feet to minimize tripping hazards. For temporary pool fencing australia, bases must be stable and non-climbable, often requiring specific designs.

-

Color & Branding:

Although galvanization is standard, panels can be powder-coated in specific RAL colors to match company branding or project aesthetics. This adds a professional finish and can also offer an additional layer of protection against environmental elements. Furthermore, options for incorporating company logos or branding elements directly onto the fence panels are available.

-

Accessories and Attachments:

Customization extends to accessories such as bracing systems for added stability, shade cloth or privacy screens attachments, barbed wire extensions for enhanced security, and specialized clamps or joining mechanisms for unique configurations.

How Customization Meets Project Demands:

Tailored temp fence australia solutions provide several key benefits:

- Optimized Performance: By matching fence specifications to environmental conditions (e.g., wind loads) and security requirements, customized solutions offer superior performance and longevity.

- Enhanced Safety & Compliance: Custom designs can ensure strict adherence to specific regulatory standards, such as those for pool safety or high-risk construction zones, mitigating liabilities.

- Improved Efficiency: Fences designed to fit exact site dimensions reduce installation time and material waste, leading to more efficient project management.

- Brand Reinforcement: Custom colors and branding transform a functional barrier into a professional extension of a company's image.

- Problem Solving: For challenging terrains or complex site layouts, off-the-shelf solutions often fall short. Customization allows for creative engineering to overcome these obstacles effectively.

Jinjiu Wire Mesh's technical team collaborates closely with clients, from initial consultation to design and production, ensuring that every customized aus temp fencing order meets the highest standards of quality and functionality, perfectly aligning with project demands.

Real-World Application Cases and Client Feedback

The practical application of australia temporary fence across various high-stakes scenarios underscores its reliability and effectiveness. Jinjiu Wire Mesh takes pride in supporting a diverse range of projects, from large-scale infrastructure developments to prominent public events, consistently receiving positive feedback for product quality and service.

Case Study 1: Major Urban Infrastructure Project, Sydney

Challenge: A large-scale urban infrastructure development in central Sydney required a robust and adaptable temporary perimeter solution. The project involved multiple phases, demanding frequent repositioning of fencing, high levels of security to protect expensive equipment, and strict adherence to public safety regulations in a high-traffic area. The fencing also needed to withstand significant wind loads typical of the metropolitan environment.

Solution: Jinjiu Wire Mesh supplied thousands of linear meters of heavy-duty australia temporary fence panels. These panels featured 4.0mm wire with a 75x150mm mesh, framed by 42mm OD pipes with 2.0mm wall thickness, all hot-dip galvanized to over 60 microns. We also provided extra-heavy concrete bases and specialized bracing systems for enhanced stability in high-wind corridors. Custom vehicle gates and pedestrian access points were integrated throughout the perimeter.

Outcome: The project manager reported seamless installation and relocation of the fencing over an 18-month period. The durable galvanization resisted corrosion despite exposure to diverse weather, and the robust construction effectively secured the site. "The Jinjiu australia temporary fencing stood up to everything we threw at it – heavy winds, constant repositioning, and daily site activity. It maintained its integrity and appearance, significantly contributing to our site safety record," commented the project manager. The project was completed on time, with no breaches related to perimeter security, and the fencing was successfully repurposed for subsequent phases.

Case Study 2: National Music Festival, Regional Victoria

Challenge: A multi-day national music festival in a regional Victorian location required extensive crowd control barriers, secure backstage areas, and designated entry/exit points for tens of thousands of attendees. The fencing needed to be quick to install and dismantle, highly visible, and reusable for future events. Weather conditions, including potential rain and strong winds, were also a consideration.

Solution: Jinjiu Wire Mesh provided event-specific temp fence australia panels, lighter than construction-grade but still highly durable. These panels had narrower mesh openings for better crowd containment and were supplied with bright orange HDPE bases for high visibility. Custom-designed entry gates with controlled access mechanisms were also part of the solution. The hot-dip galvanized finish ensured no rust stains on the ground, a common concern for event organizers.

Outcome: The event management team praised the efficiency of installation and removal. "The Jinjiu temporary fencing was incredibly easy to work with. Our crew managed setup and takedown swiftly, which is crucial for event logistics. The fences were sturdy, looked professional, and handled the large crowds perfectly. We're already planning to use Jinjiu for next year's festival," stated the event coordinator. The reusability of the fencing meant significant cost savings for the organizers over multiple events.

Case Study 3: Residential Pool Construction, Brisbane

Challenge: A residential builder in Brisbane required temporary pool fencing that strictly complied with Queensland's stringent pool safety regulations (AS 1926.1-2012) during the construction of several new swimming pools. The fencing needed to be secure, non-climbable, and easily movable as the construction progressed.

Solution: Jinjiu Wire Mesh supplied specialized temporary pool fencing australia panels specifically engineered to meet AS 1926.1-2012. These fences featured a minimum height of 1.2m, small vertical mesh openings (less than 100mm) and no horizontal gaps greater than 10mm below 900mm height, preventing small children from climbing through or over. Secure, self-closing gates with child-resistant latches were also provided.

Outcome: The builder reported complete compliance with local regulations, passing all inspections without issues. "The Jinjiu pool fencing gave us complete peace of mind. It was clearly designed with the Australian standards in mind, making installation straightforward and ensuring our sites were fully compliant and safe for families. It's now our go-to for aus temp fencing on all our pool projects," said the construction manager. This case highlights Jinjiu's commitment to not just general quality, but also specific regulatory compliance vital for certain applications.

These real-world examples, combined with consistent positive client feedback, demonstrate Jinjiu Wire Mesh's expertise, experience, and the trustworthiness of its australia temporary fence products in meeting diverse and demanding requirements across the Australian landscape.

Ensuring Trustworthiness: Quality Assurance & Support

Trust is the cornerstone of any successful business relationship, especially when it comes to essential safety and security products like australia temporary fence. Jinjiu Wire Mesh builds this trust through rigorous quality assurance, transparent certifications, comprehensive warranties, and dedicated customer support.

Certifications and Standards Compliance:

Our commitment to quality is underpinned by adherence to globally recognized standards and specific Australian regulations:

- ISO 9001:2015 Quality Management System: Jinjiu Wire Mesh operates under an internationally certified ISO 9001:2015 Quality Management System. This certification demonstrates our consistent ability to provide products and services that meet customer and regulatory requirements, and our commitment to continuous improvement across all manufacturing and operational processes.

- AS 4687-2007 (Temporary Fencing and Hoardings): All our general-purpose australia temporary fencing products are manufactured to comply with this Australian Standard, ensuring they meet the prescribed performance criteria for temporary fences and hoardings used on construction sites and other applications. This covers aspects like panel strength, stability, and safety.

- AS 1926.1-2012 (Swimming Pool Safety - Safety Barriers for Swimming Pools): Our specialized temporary pool fencing australia products are specifically designed and tested to meet the stringent requirements of this critical Australian Standard. This ensures that the fences provide an effective barrier to prevent unsupervised access by young children to swimming pools, a vital public safety concern.

- AS/NZS 4680:2006 (Hot-dip galvanized (zinc) coatings on fabricated ferrous articles): Our galvanization process strictly adheres to this standard, guaranteeing the specified minimum thickness and quality of the zinc coating, which is crucial for the long-term corrosion resistance and lifespan of the fence panels.

These certifications and compliance statements are not mere formalities; they represent a fundamental aspect of our manufacturing philosophy, ensuring that every aus temp fencing panel leaving our facility is of the highest caliber.

Transparent Warranty Information:

Jinjiu Wire Mesh stands behind the quality of its products with a comprehensive warranty. We offer a standard 5-year warranty against manufacturing defects and premature corrosion (due to galvanization failure) under normal usage conditions. For our heavy-duty and premium temporary fence australia ranges, this warranty can extend to 10 years or more, reflecting our confidence in their superior durability and lifespan. Full warranty terms and conditions are provided with every quote and order, clearly outlining coverage and limitations, providing our clients with peace of mind.

Reliable Delivery Cycle Information:

Understanding that project timelines are critical, Jinjiu Wire Mesh is committed to efficient and reliable delivery. Our typical production lead time for standard australia temporary fence orders is 2-4 weeks, depending on order volume and current production schedules. For customized or very large orders, lead times may extend to 4-6 weeks. We work closely with trusted shipping partners to ensure prompt and secure delivery to major Australian ports (e.g., Sydney, Melbourne, Brisbane, Fremantle) or directly to site, based on client requirements. Expedited production and shipping options can be discussed for urgent projects, demonstrating our flexibility and client-centric approach.

Dedicated Customer Support:

Our commitment to clients extends far beyond the sale. Jinjiu Wire Mesh provides dedicated customer support throughout the entire process:

- Pre-sales Consultation: Our experienced team offers expert advice on product selection, technical specifications, and compliance requirements, helping clients choose the most suitable temp fence australia solution for their needs.

- Order Tracking and Communication: Clients receive regular updates on their order status, from production milestones to shipping and delivery estimates.

- After-sales Assistance: We offer comprehensive support for any post-delivery queries, installation guidance, or warranty claims. Our technical team is available to address concerns promptly and professionally, ensuring complete client satisfaction.

By integrating rigorous quality control, transparent warranties, dependable logistics, and responsive customer service, Jinjiu Wire Mesh establishes itself not just as a supplier, but as a trustworthy partner in providing high-quality australia temporary fence solutions.

Frequently Asked Questions (FAQ) about Australia Temporary Fence

To provide further clarity and demonstrate our deep expertise in the field of australia temporary fence, here are answers to some common professional and technical questions:

Q1: What is the primary material used for Australia Temporary Fence panels, and why?

A1: The primary material used is high-quality low-carbon steel wire for the mesh and steel pipes for the frame. This material is chosen for its inherent strength, ductility, and weldability. Crucially, it is then subjected to hot-dip galvanization, which provides superior corrosion resistance by forming a metallurgical bond between the zinc coating and the steel. This process is essential for protecting the fence against Australia's diverse and often harsh environmental conditions, ensuring a long lifespan for the australia temporary fence.

Q2: How does the hot-dip galvanization process enhance the lifespan and durability of the fence?

A2: Hot-dip galvanization involves immersing the fabricated steel fence panels into a bath of molten zinc. This creates a multi-layered zinc-iron alloy coating that is metallurgically bonded to the steel substrate, followed by an outer layer of pure zinc. This coating acts as a robust barrier against rust and corrosion, even if the surface is scratched, due to zinc's sacrificial protection properties. It significantly extends the fence's lifespan, typically to 5-15 years or more, especially compared to electro-galvanized or painted alternatives, making it ideal for australia temporary fencing exposed to outdoor elements.

Q3: What Australian Standards should Australia Temporary Fence comply with, and why are they important?

A3: For general construction and event temporary fencing, the primary standard is AS 4687-2007 (Temporary Fencing and Hoardings). For temporary pool fencing australia, compliance with AS 1926.1-2012 (Swimming Pool Safety - Safety Barriers for Swimming Pools) is mandatory. Additionally, the galvanization process should meet AS/NZS 4680:2006 (Hot-dip galvanized (zinc) coatings on fabricated ferrous articles). These standards are crucial because they ensure the fencing meets minimum requirements for strength, stability, safety, and durability, reducing risks, ensuring public protection, and satisfying legal and insurance requirements for any temp fence australia deployment.

Q4: Can Australia Temporary Fence be used on uneven terrain or sloped surfaces? If so, how?

A4: Yes, australia temporary fence is highly adaptable to uneven terrain or sloped surfaces. The modular design allows individual panels to be stepped or angled to follow the contours of the ground. For significant slopes, specialized bracing systems, additional fence feet, or custom-fabricated panel heights can be utilized to maintain stability and close any potential gaps at the bottom of the fence line. This flexibility is a key advantage of aus temp fencing.

Q5: What are the typical dimensions (height and width) of a standard Australia Temporary Fence panel?

A5: While variations exist for custom solutions, the most common standard dimensions for a australia temporary fence panel are 1.8 meters (approximately 6 feet) or 2.1 meters (approximately 7 feet) in height, and 2.4 meters (approximately 8 feet) in width. These dimensions strike a balance between providing effective security and ease of handling for installation and transport.

Q6: How are the temporary fence panels secured together, and what components are needed for a complete installation?

A6: Temporary fence australia panels are typically secured together using galvanized steel clamps, also known as clips. These clamps connect the vertical pipes of adjacent panels, ensuring a continuous and rigid barrier. For a complete installation, you need the fence panels, supporting fence feet (bases, typically made of HDPE or concrete), and the clamps. Additional components like bracing systems or gates may be needed depending on the specific application.

Q7: What is the estimated lifespan of a high-quality Australia Temporary Fence, and what factors influence it?

A7: A high-quality, hot-dip galvanized australia temporary fence can have an estimated lifespan of 5 to 15 years or even longer. Key factors influencing its lifespan include: the thickness and quality of the hot-dip galvanization (thicker coating offers more protection); the wire gauge and pipe wall thickness (heavier materials resist damage better); the frequency of use and abuse (constant installation/dismantling or impacts can reduce life); and environmental exposure (coastal areas with salt spray are more corrosive than inland, drier regions). Proper handling, storage, and occasional cleaning can also extend its service life.

Conclusion: The Indispensable Role of Australia Temporary Fence

The australia temporary fence stands as an indispensable asset in modern Australian industry, providing critical solutions for safety, security, and site management across an expansive array of applications. From the bustling perimeters of major construction projects to the controlled environments of vibrant festivals and the stringent safety requirements of temporary pool enclosures, its adaptability and robust performance are unmatched. The meticulous manufacturing process, centered on high-grade galvanized steel, ensures that each panel offers exceptional durability, resistance to Australia's harsh climate, and an extended service life, representing a sound investment for any enterprise.

Choosing a reputable manufacturer like Jinjiu Wire Mesh is paramount. Our commitment to adhering to stringent Australian Standards such as AS 4687-2007 and AS 1926.1-2012, coupled with our ISO 9001 certified quality management system, ensures that every australia temporary fencing product delivered meets the highest benchmarks for quality, reliability, and safety. Our expertise in custom solutions, robust manufacturing processes, comprehensive warranty, and dedicated customer support further solidify our position as a trusted partner.

As Australia continues its trajectory of growth in construction, infrastructure, and event management, the demand for reliable temp fence australia solutions will only intensify. Investing in high-quality, compliant temporary fencing not only safeguards personnel and assets but also streamlines project execution and minimizes potential liabilities. Jinjiu Wire Mesh is dedicated to empowering businesses with superior temporary fence australia products that are engineered for excellence and built to last, providing peace of mind and operational efficiency for every project, every time. Our expansive reach and proven track record make us the go-to choice for all aus temp fencing requirements, ensuring projects proceed safely, securely, and successfully.

References & Further Reading:

- Standards Australia. (2007). AS 4687-2007: Temporary fencing and hoardings. Retrieved from Standards Australia InfoStore or your local standards library.

- Standards Australia. (2012). AS 1926.1-2012: Swimming pool safety - Safety barriers for swimming pools. Retrieved from Standards Australia InfoStore.

- Standards Australia. (2006). AS/NZS 4680:2006: Hot-dip galvanized (zinc) coatings on fabricated ferrous articles. Retrieved from Standards Australia InfoStore.

- Galvanizers Association of Australia. (n.d.). Why Galvanize?. Retrieved from https://www.gaa.com.au/why-galvanize/

- Construction Industry Trends in Australia (various reports from organisations like Master Builders Australia or BIS Oxford Economics are often cited, specific links vary annually). Example general reference: Australian Bureau of Statistics (ABS) Construction Work Done data.

Related Products

Related News