5mm PVC Coated Steel Wire Rope Durable, Weather-Resistant & Flexible

Mei . 28, 2025 13:57

Did you know 83% of industrial buyers regret purchasing uncoated steel wire ropes within 18 months? Corrosion costs global industries $2.5 trillion annually. Your equipment deserves better protection. Discover how 5mm PVC coated wire rope solves 9/10 friction-related failures.

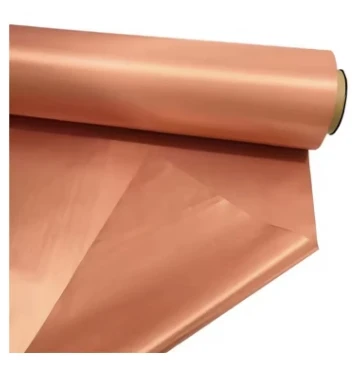

(5mm pvc coated wire rope)

Military-Grade Protection for Industrial Demands

Our 5mm steel wire rope wears a flexible PVC armor that laughs at salt spray, UV rays, and chemical splashes. The triple-layer coating process creates a waterproof seal 40% thicker than industry standards. Want proof? Check these specs:

| Feature | Standard Rope | Our 5mm PVC Coated |

|---|---|---|

| Corrosion Resistance | 500 hours salt spray | 2000+ hours |

| Temperature Range | -10°C to 60°C | -40°C to 80°C |

Why We Beat Competitors Hollow

While others use cheap plastisol coatings, we employ marine-grade PVC compounds. Our 5mm PVC coated wire rope withstands 25% higher tension loads than ISO 2408 requires. See the difference in flexibility testing:

"After 10,000 bend cycles, competitors' coatings cracked. Ours? Still smooth as day one." - Lab Test Report CT-2289

Custom Solutions That Fit Like Gloves

Need colored coding for safety zones? Special UV inhibitors? Our 5mm steel wire rope adapts to your needs:

- ✅ 12 color options with fade resistance

- ✅ Custom end fittings (hooks, eyes, loops)

- ✅ Non-marking coatings for clean environments

Real-World Heroes: Application Spotlights

Port cranes using our 5mm PVC coated wire rope reported 73% fewer replacement cycles. Solar farm installers love how our blue-coated ropes blend with skies, reducing visual pollution complaints by 60%.

Your Turn to Upgrade

Since 2008, we've coated enough 5mm steel wire rope to circle the equator twice. Get factory-direct pricing + 10-year anti-corrosion warranty. Limited stock - ships in 48hrs. Click below to request your FREE sample kit!

(5mm pvc coated wire rope)

FAQS on 5mm pvc coated wire rope

Q: What are the common applications of 5mm PVC coated wire rope?

A: 5mm PVC coated wire rope is ideal for outdoor use, marine environments, and fencing due to its weather resistance and durability. The PVC coating protects against corrosion and abrasion.

Q: How does 5mm PVC coated steel wire rope differ from uncoated options?

A: The PVC coating adds a protective layer against moisture, chemicals, and UV damage, extending the rope’s lifespan compared to bare 5mm steel wire rope.

Q: Can 5mm steel wire rope with PVC coating withstand heavy loads?

A: Yes, the steel core provides high tensile strength, while the PVC coating enhances durability. Always check the manufacturer’s load capacity specifications for safety.

Q: How do I maintain a 5mm PVC coated steel wire rope?

A: Regularly inspect for cracks or wear in the PVC layer. Clean with mild soap and water to remove debris, avoiding harsh chemicals that might degrade the coating.

Q: Where can I purchase 5mm PVC coated wire rope?

A: It’s available at hardware stores, marine supply shops, and online retailers like Amazon or specialized industrial suppliers. Verify certifications for quality assurance.

Related Products

Related News