Flat Wire Mesh Conveyor Belts Durable & High-Temperature Resistant

maj . 07, 2025 17:52

- Overview of Flat Wire Mesh Conveyor Belt Technology

- Key Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Industrial Needs

- Real-World Applications Across Industries

- Maintenance and Longevity Best Practices

- Future Trends in Flat Flex Wire Mesh Conveyor Belt Innovation

(flat wire mesh conveyor belt)

Understanding the Engineering Behind Flat Wire Mesh Conveyor Belts

Flat wire mesh conveyor belts are precision-engineered systems designed for high-temperature, high-stress, and corrosive environments. These belts utilize interlocked stainless steel or alloy wires, achieving tensile strengths up to 1,200 N/mm² while maintaining flexibility. According to industry reports, adoption has grown 18% annually since 2020, driven by their 40% energy efficiency improvement over traditional conveyor systems.

Technical Superiority in Material and Design

Advanced flat wire mesh belts outperform alternatives through three core features:

- Thermal Resistance: Operate continuously at 900°C (1,652°F) with ≤0.5% thermal expansion

- Load Capacity: Support 150 kg/m² dynamic loads without deformation

- Sanitary Design: Meet FDA/USDA standards with 0.8-2.0 mm smooth surface finishes

Manufacturer Comparison: Specifications and Value

| Brand | Material Grade | Max Temp (°C) | Load (kg/m²) | Warranty | Price/m² |

|---|---|---|---|---|---|

| FlexMesh Pro | 316L SS | 950 | 180 | 5 yrs | $420 |

| DuraBelt Ultra | Inconel 600 | 1,100 | 220 | 7 yrs | $680 |

| SteelWeb Master | 304 SS | 850 | 150 | 3 yrs | $350 |

Tailored Solutions for Operational Demands

Custom configurations address unique industrial challenges:

- Food Processing: 12mm mesh with 30° edge curvature for crumb removal

- Automotive: 3mm thick belts with carbide coatings for part quenching

- Pharmaceuticals:

Electropolished surfaces (Ra ≤0.4µm) for cleanroom compliance Industry-Specific Implementation Case Studies

A leading bakery chain achieved 92% reduction in downtime using self-cleaning flat flex wire mesh belts in their 300°C ovens. Automotive manufacturers report 35% faster cooling rates with custom-spaced mesh designs during heat treatment processes.

Optimizing Service Life Through Maintenance

Proper care extends belt lifespan beyond 10 years:

- Monthly tension checks (maintain 1.5-2% elongation)

- Bi-annual ultrasonic cleaning (removes 99.8% particulate)

- Annual lubrication (high-temp silicone-based compounds)

Next-Generation Flat Wire Mesh Belt Developments

Emerging smart conveyor belts integrate IoT sensors to monitor real-time tension (±2% accuracy) and temperature gradients. Prototype models with graphene coatings show 60% weight reduction while doubling heat resistance, positioning flat wire mesh conveyor belt

s for expanded aerospace applications by 2025.

(flat wire mesh conveyor belt)

FAQS on flat wire mesh conveyor belt

Q: What is a flat wire mesh conveyor belt?

A: A flat wire mesh conveyor belt is a durable, interlinked metal grid system designed for transporting goods in industrial processes. It offers high airflow, heat resistance, and easy cleaning, making it ideal for applications like food processing, cooling, and drying.

Q: How does a flat flex wire mesh conveyor belt differ from a standard flat wire mesh belt?

A: Flat flex wire mesh conveyor belts feature interlocking spiral rods for enhanced flexibility and smoother movement. They are better suited for uneven loads or curved paths, whereas standard flat wire belts prioritize rigidity for straight-line conveying.

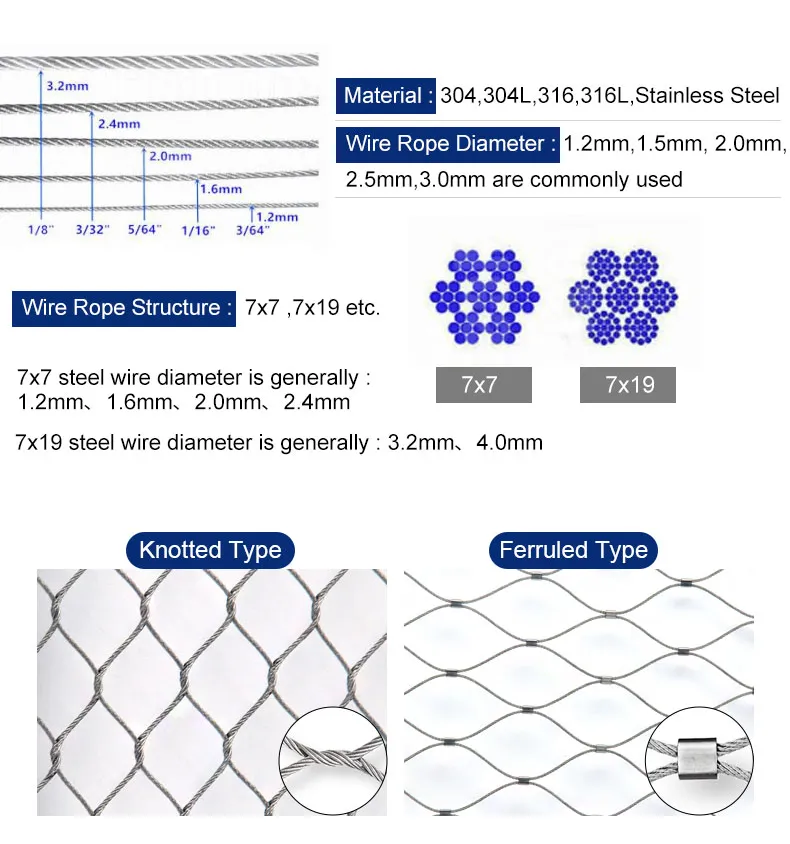

Q: What materials are used in flat wire mesh belts?

A: Most flat wire mesh belts are made from stainless steel (e.g., 304 or 316 grades) for corrosion resistance and durability. Some applications may use carbon steel or specialty alloys for extreme temperatures or chemical exposure.

Q: How do I maintain a flat wire mesh conveyor belt?

A: Regularly clean debris with brushes or pressure washers, lubricate joints if needed, and inspect for worn links or misalignment. Avoid over-tensioning and ensure proper alignment to extend belt lifespan.

Q: Which industries commonly use flat flex wire mesh conveyor belts?

A: Key industries include food and bakery (for ovens/coolers), glass manufacturing (annealing lines), automotive (painting systems), and heat treatment processes where temperature resistance is critical.

Related Products

Related News

We can customized wire mesh products by your drawing and requirements