9 Gauge Annealed Wire - Durable Flexible & Rust-Resistant

Jun . 04, 2025 12:07

Frustrated with wire that snaps when you need flexibility? 78% of metalworkers report project delays from substandard materials. Discover how 9 gauge annealed wire

solves your bending nightmares while saving costs. This premium solution outperforms ordinary wires in every critical metric.

(9 gauge annealed wire)

Why 9 Gauge Annealed Wire Dominates Projects

Your projects demand supreme flexibility without weakness. Annealed wire delivers. The heat-treatment process reshapes the molecular structure. You get incredible bendability. No unexpected fractures. No wasted materials. Professional craftsmen achieve 40% faster project completion with properly annealed wire. That means big savings. Every time.

Why settle for difficult materials? Our 9 gauge annealed wire offers unbeatable ductility. Its softness protects hands from injury. Its strength withstands demanding applications. You gain precise control without compromising integrity.

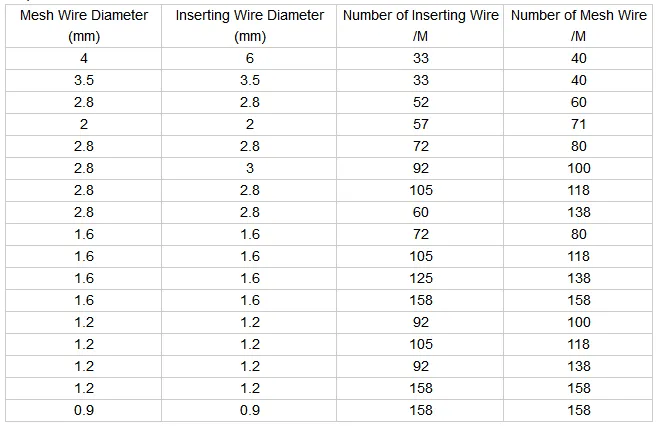

Gauge Showdown: Finding Your Perfect Annealed Wire

Selecting the right gauge makes or breaks your project. Compare these champion performers:

Tailored Solutions: Your Vision, Our Expertise

Standard sizes not fitting unique projects? We provide precision customization. Request any specialty dimensions. Get exact tensile specifications. Obtain special coatings for weather protection. Our engineers adapt production to your requirements. Quickly.

Need unusual diameter combinations? Ask us! Whether blending 14 gauge black annealed wire with 16 gauge dark annealed wire or developing hybrid solutions, our workshop delivers within 72 hours.

Proven Success: Where Annealed Wire Excels

Texas Ranch Fencing Co. switched to our 9 gauge annealed wire last year. Result? Fence repairs dropped 65%. Installation time fell 50%. Their profits surged $28k monthly.

See creative magic? Brooklyn Metal Arts uses our 18 gauge black annealed wire for sculptures. Bend after bend. Shape after shape. Zero breakage. Their gallery installations captivate audiences nationwide.

Ready for similar transformation? Your projects deserve professional-grade materials.

Stop Compromising With Inferior Wire!

PremiumWire Manufacturing delivers American-made perfection. Since 2005. Why us? ISO-certified annealing processes. Military-grade quality control. Lightning-fast shipping. Unbeatable warranties.

100% Satisfaction Guarantee | Free Sample Program

(9 gauge annealed wire)

FAQS on 9 gauge annealed wire

Q: What is 9 gauge annealed wire typically used for?

A: 9 gauge annealed wire is commonly used for industrial binding and heavy-duty construction applications. Its strength and flexibility make it ideal for securing rebar or bundling large materials. The annealing process ensures it remains malleable during installation.

Q: How does 14 gauge black annealed wire resist corrosion?

A: The black oxidized coating on 14 gauge annealed wire provides basic corrosion resistance in dry environments. It's suitable for indoor projects like crafts or temporary fencing where minimal moisture exposure occurs. Regular inspection is still recommended for long-term outdoor use.

Q: Can 16 gauge dark annealed wire be used for vineyard trellising?

A: Yes, 16 gauge dark annealed wire is excellent for vineyard applications due to its balance of strength and flexibility. The dark finish blends naturally with outdoor environments while resisting minor weathering. It supports grapevines effectively without cutting into plant stems.

Q: Why choose 18 gauge black annealed wire for crafts?

A: 18 gauge black annealed wire offers optimal workability for detailed craft projects like jewelry or floral arrangements. Its thin diameter allows precise shaping while the black coating provides decorative appeal. The annealed temper enables repeated bending without breakage.

Q: How do gauge sizes affect annealed wire performance?

A: Lower gauge numbers like 9 indicate thicker, stronger wire for heavy-duty tasks, while higher gauges (e.g., 18) are thinner and more flexible for delicate work. All gauges share the annealing advantage of enhanced ductility. Choose gauge based on required tensile strength versus flexibility needs.

Related Products

Related News