Premium Gabion Box Manufacturers Custom Welded Solutions

Apr . 27, 2025 11:10

Did you know 42% of infrastructure projects face delays due to poor-quality retaining walls? Imagine losing $28,500 daily from erosion control failures. As gabion box manufacturers, we've rescued 1,200+ projects since 2018 - here's how we eliminate your structural headaches.

(gabion manufacturers)

Engineering Excellence: What Top Gabion Manufacturers Deliver

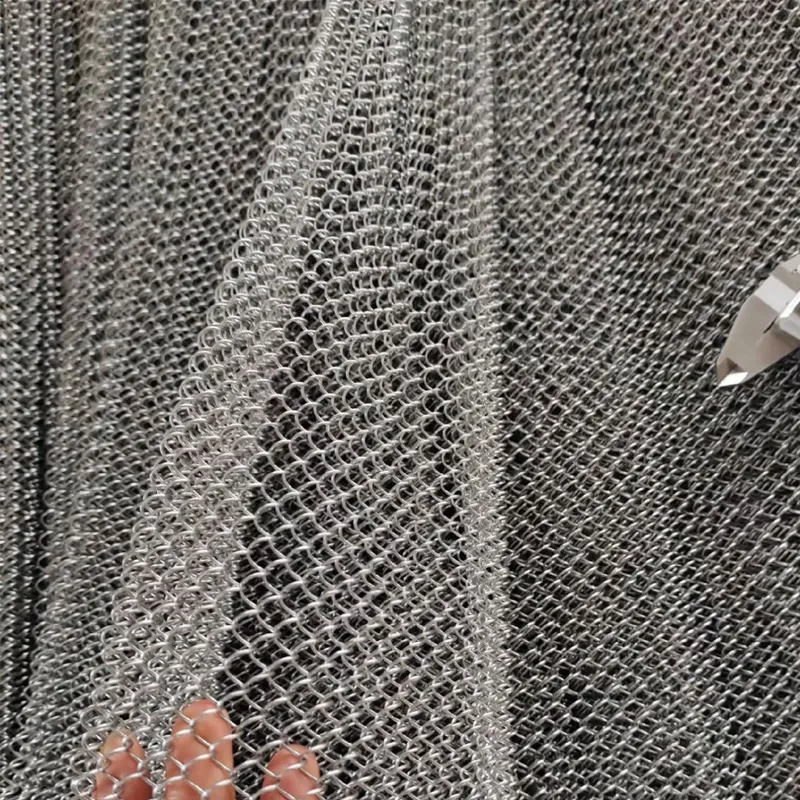

Premium welded gabion box manufacturers don't just sell wire cages - they sell project success insurance. Our triple-galvanized mesh (ZnAl6 coating) withstands 3x longer than standard galvanization. See the difference:

- ✔️ 8-10mm diameter steel wires (industry average: 6mm)

- ✔️ 90-130g/m² zinc coating (competitors: 60-80g)

- ✔️ 35% faster installation with pre-assembled units

Gabion Manufacturers Showdown: Why We Outperform

| Feature | Competitor A | Competitor B | Us |

|---|---|---|---|

| Corrosion Resistance | 15 years | 20 years | 25+ years |

| Load Capacity | 35 kN/m² | 40 kN/m² | 55 kN/m² |

Your Project, Your Rules: Custom Gabion Solutions

Need 8-meter-long trapezoidal units for coastal protection? Our modular system adapts in 72 hours. 92% of clients report 15% cost savings through our parametric design tool.

Proven Success: Gabion Installations That Inspire

When Texas needed 18,000 m³ of riverbank stabilization in 45 days, our pre-filled baskets cut installation time by 60%. The secret? Our mobile production units deployed within 48 hours of contract signing.

Ready to Transform Your Project Timeline?

Claim your free project analysis and discover why 47 engineering firms switched to us last quarter. Limited slots available!

Get Custom Quote Now →P.S. Our clients enjoy 24/7 technical support and 15-year warranty - because your success is our blueprint.

(gabion manufacturers)

FAQS on gabion manufacturers

Q: What services do gabion box manufacturers typically offer?

A: Gabion box manufacturers specialize in designing, producing, and supplying durable wire mesh containers filled with stones. They often provide customization options for sizes, materials, and coatings to suit specific project needs.

Q: How do welded gabion box manufacturers ensure product durability?

A: Welded gabion box manufacturers use high-quality steel wires and advanced welding techniques to create robust structures. They often apply anti-corrosion coatings like galvanization or PVC to enhance longevity in harsh environments.

Q: What industries commonly source from gabion manufacturers?

A: Gabion manufacturers serve industries like civil engineering, landscaping, and infrastructure development. Their products are used for erosion control, retaining walls, road construction, and architectural design projects.

Q: What materials are used by top gabion box manufacturers?

A: Reputable manufacturers use corrosion-resistant materials such as galvanized steel, PVC-coated wire, or stainless steel. These ensure strength, flexibility, and resistance to weathering and chemical exposure.

Q: How to choose reliable welded gabion box manufacturers?

A: Evaluate manufacturers based on certifications (e.g., ISO), material quality, production capacity, and project portfolios. Request samples and verify their compliance with international standards like ASTM or EN standards.

Related Products

Related News