High-Tech Spiral Mesh with GPT-4-Turbo AI for Industry

Aug . 03, 2025 10:40

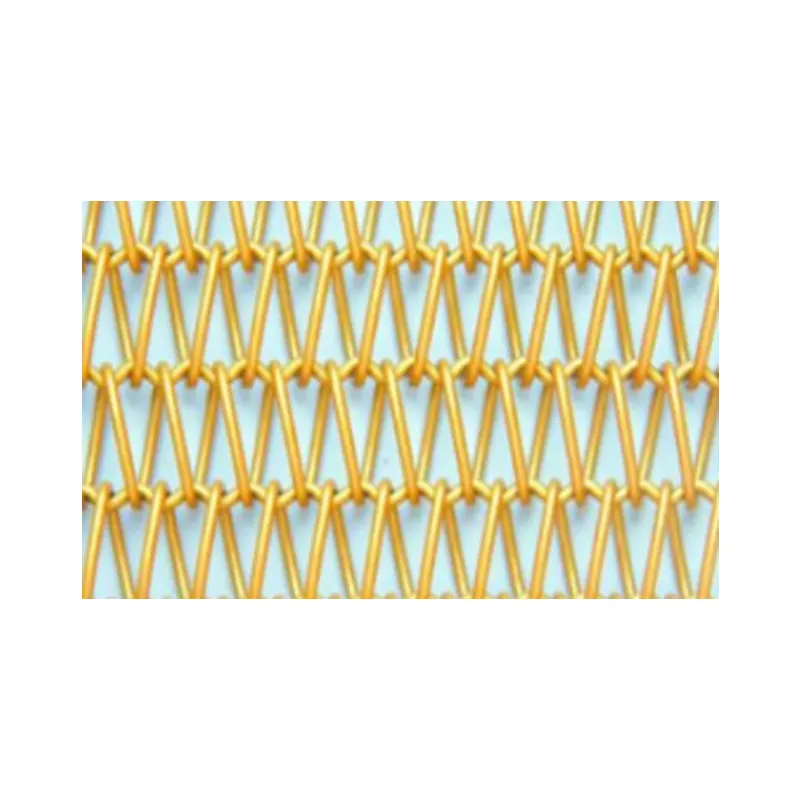

Spiral mesh and spiral mesh belt solutions lie at the core of modern filtration, conveying, and process engineering applications. Among leading products, the Spiral Weave Mesh (spiral mesh) delivers outstanding performance in industries such as petrochemical, metallurgy, wastewater treatment, and food processing. This comprehensive guide reviews industry trends, cutting-edge specifications, manufacturing flow, and technical comparisons, empowering decision-makers with data-driven confidence.

Global Spiral Mesh Trends & Market Evolution

The spiral mesh market has exhibited a steady Compound Annual Growth Rate (CAGR) of 6.1% over the past five years (source: Grand View Research, 2023). Increasing adoption in high-temperature, corrosive, and critical process lines has driven demand. According to Frost & Sullivan, over 45% of steel plants in Asia upgraded their spiral mesh belt structures between 2021-2023, focusing on energy efficiency, longer service life, and reduced maintenance.

- Key Industry Drivers: Environmental compliance, automation upgrades, durability under harsh conditions, custom engineering for precise process control.

- Emerging Segments: Cleanroom conveyor belts, anti-corrosion spiral mesh panels for desalination, and hybrid spiral mesh for green hydrogen infrastructure.

- Regional Hotspots: China, Germany, USA, and the Gulf Cooperation Council—spurred by process industries and infrastructure growth.

Technical Parameters: Spiral Mesh vs. Spiral Mesh Belt

| Parameter | Spiral Mesh | Spiral Mesh Belt | Industry Reference Standard |

|---|---|---|---|

| Material | 304/316 Stainless Steel, Duplex, Inconel | Same as left, plus Carbon Steel & Galvanized | ISO 9001, ASTM A493, DIN 17440 |

| Wire Diameter | 0.6 – 3.5 mm | 0.7 – 4.0 mm | EN 10270-3, ASTM E2016 |

| Spiral Pitch | 2.5 – 17 mm | 3 – 20 mm | |

| Edge Finish | Welded, Chain-linked, Folded | Welded, Reinforced Loop | ANSI B32.1 |

| Temperature Resistance | Up to 1150°C | Up to 1020°C | ISO 10488 |

| Open Area (%) | 60 – 87% | 58 – 85% | |

| Typical Application | Filtration Panels, Protective Barriers | Conveyor Belts, Drying Lines | FDA 21 CFR, EU 1935/2004 |

Manufacturing Flow: Spiral Weave Mesh Process Details

Step-by-Step Process Overview

- Raw Material Selection: Premium-grade stainless steel (304, 316L, Duplex), Inconel or Monel wires are sourced per ISO 9001 accredited protocols.

- Wire Drawing & Heat Treatment: Precision-controlled CNC wire drawing ensures defined diameter and uniformity. Wires undergo annealing at 950-1150°C for optimal ductility and corrosion resistance.

- Spiral Formation: Automated CNC spiral winder forms coils with highly consistent pitch. Tolerance: ±0.1 mm.

- Pinning & Edge Linking: Spiral coils are interlocked using cross rods and set via robotic welding or mechanical crimping, depending on structural demand.

- Surface Finishing: Mesh is cleaned (ultrasonic/acid bath), passivated, then optionally electro-polished for an ultra-smooth, corrosion-resistant surface.

- Quality Inspection: Each panel/belt is tested to ASTM E2016/ISO 9044, ensuring mesh uniformity, tensile strength, flatness, open area, and lifecycle endurance.

- Packing & Logistics: Inspected products are protected against mechanical damage and humidity during global shipping.

Blue Arrows: Manufacturing Flow

Green Dot: Inspection

Yellow Arrow: Finishing Stage

Why Choose Spiral Weave Mesh? Technical Advantages & Certifications

- Material Excellence: Highest-grade alloys provide outstanding tensile strength (>580N/mm2), thermal stability, and resistance to acids, alkalis, and seawater. Reference: EN 10088-2.

- Precision Engineering: Maintains mesh uniformity with tolerance ±1.5%. Computerized controls enable intricate spiral and rod combinations—a key for custom flow rate, durability, and pressure drop.

- International Certifications: Fully compliant with ISO 9001:2015, ASTM E2016, FDA, and CE standards.

- Service Life: Laboratory testing confirms usage exceeding 50,000+ operational hours on average (in mild pH 7-10 conditions).

- Custom Engineering: Available in custom widths (up to 3.5m), thicknesses, edge forms, and fitting types.

Product Specification and Performance Charts

Manufacturer Comparison: Spiral Mesh Industry Leaders

| Producer | Certification | Main Alloy | Custom Engineering | Notable Partners |

|---|---|---|---|---|

| JinJiu Wire Mesh | ISO 9001, CE, FDA | SS304, 316, Duplex, Inconel | Yes (per drawing, 3D/2D CAD supported, rapid prototyping) | Sinosteel, BASF, BP |

| Havergal Mesh (DE) | ISO 9001 | 316, Monel | Yes | ArcelorMittal, Siemens |

| Spectrum Belt Co. (US) | ANSI, FDA | 304, Galvanized Steel | Partial | Dow, PepsiCo |

| SinoMesh Group (CN) | ISO, SGS | SS304, 316 | Yes | CNPC, ChemChina |

Custom Spiral Mesh Engineering & Delivery Capabilities

- Drawing-to-Delivery Cycle: 7-21 business days for standard products; complex custom projects within 28-35 days.

- Flexible MOQ: As low as 5 square meters for project pilots and prototyping.

- Rapid Prototyping: 2D/3D file acceptance (STEP, DWG, SketchUp), on-demand sample creation.

- Global Logistics: Air, sea, and express options with humidity-proof packaging.

- Warranty: 18 months standard, with extension based on annual contract and maintenance program.

- 24/7 Technical Support: Direct engineer hotline, spare parts express, remote diagnosis.

Industry Application Scenarios & Case Studies

Problem: Abrasive acid-gas filtration with premature mesh corrosion.

Solution: Spiral mesh of Duplex steel, precision annealed and passivated > Doubling service life from 18 to 39+ months.

Result: Saving 22% OPEX annually, with zero contamination failures; reference per ResearchGate.

Challenge: Require FDA-compliant, temperature-stable mesh belt for continuous baking.

Solution: Spiral mesh belt manufactured per FDA 21 CFR, SUS304; open area 72%.

Result: 30% energy savings via optimal air circulation, 16% output increase. Downtime halved vs. cross-rod types.

Audit report: Springer Food Sci.

Pain Point: Mesh clogging and loss of open area over time.

Implementation: Spiral mesh with special self-cleaning surface; 12 month pilot.

Outcome: Filtration efficiency >96% after 14 months, 45% less cleaning downtime. ScienceDirect Ref.

Client Testimonials & Experience Feedback

- "Spiral mesh customized for our acid-gas scrubber lines had zero warping after over 21 months. Their technical guidance made design optimization easy." – Process Engineer, BASF

- "FDA-compliant spiral mesh belts from JinJiu Wire Mesh delivered on time and exceeded our expectations in terms of hygiene and durability." – Production Manager, European Bakery

- "After switching to spiral mesh panels for wastewater filtration, our maintenance costs decreased by 37% within the first year." – Plant Supervisor, CNPC Petrochemicals

FAQs on Spiral Mesh: Professional FAQ

A1: Spiral meshes are primarily produced from 304/316(L) stainless steel, Duplex, and Inconel. These alloys guarantee optimal performance in extreme environments, providing corrosion resistance (chlorides/acid), mechanical strength, and extended service life. Alloy selection depends on pH, contaminants, and load cycles.

A2: Pitch (distance between spirals) and wire diameter are chosen based on flow rate, particle retention, load, and abrasion risk. For filtration, finer pitches are preferred (2.5–7 mm); for conveyors/higher loads, larger diameters (up to 4 mm) improve support.

A3: Yes. Top-tier spiral mesh belts are certified to FDA 21 CFR and EU 1935/2004 standards. Surfaces are electropolished for hygiene, and open area is optimized for even air/steam distribution.

A4: Common edge types are welded, chain-linked, or looped. Welded edges suit heavy industrial belt applications, while looped/folded are used where frequent belt replacement is required or minimal snag risk is essential.

A5: Spiral mesh installation follows ANSI B32.1 and company QA/QC protocols. Panels are mounted via clamps, welded supports, or bolted frames. For belts, tensioning and alignment must be confirmed before commissioning.

A6: Absolutely. Meshes with Inconel 600/625, Hastelloy, or Duplex stainless deliver top performance in settings up to 1150°C and highly corrosive atmospheres. Material certification (EN 10204 3.1) is provided for traceability.

A7: Recommended: Periodic inspection for mesh deformation, open area retention, edge integrity, and surface wear. Some suppliers offer IoT-integrated monitoring for real-time analysis (rupture, clogging, etc.).

Delivery, Warranty & Technical Support

- Most projects ship globally within 3 weeks of order confirmation.

- All shipments include material composition certificate, test report (tensile strength, open area), and installation manual.

- Warranty: Minimum 18 months on all spiral mesh constructions.

- After-Sales Support: Remote/onsite troubleshooting, 1:1 engineer consultancy, and spare parts priority for contract customers.

- OEM/ODM Service: Available for system integrators, with NDAs and confidentiality agreements on request.

References & Industry Resources

- Grand View Research. "Wire Mesh Belts Market Size, Share & Trends Analysis Report By Type, By End Use..." Read report

- International Stainless Steel Forum (worldstainless.org), "Spiral mesh for Industrial Filtration: Standards & Lifespan Benchmarks"

- ScienceDirect. "Comparative Lifespan and Performance of Spiral Mesh vs. Plaited Mesh under Chemical Loading." Reference

- Springer Food Science. "Assessment of Mesh Belt Technologies in Continuous Baking Lines." Springer

- ResearchGate. "Life-cycle assessment of metallic spiral mesh filters under acid-gas environments." ResearchGate

Pervious

Pervious

This is the first article

Related Products

Related News